Max Buchholz first introduced Buchholz relay in the year 1921 and was named after him. A relay is basically an appliance of security utilized in electrical transmission systems such as distribution and transmission. Buchholz relay is efficient in protection again arching, fractional discharge, hot spots, and current leakage in electrical systems. The device has an important impact when it comes to economic prospects and is also enhancing the life of equipment of electrical systems. This article will serve as a Buchholz Relay manual.

Buchholz Relay Definition

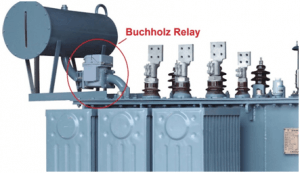

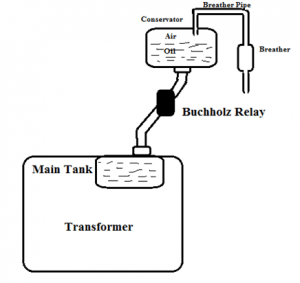

To understand What is Buchholz relay, head to its definition. The Buchholz relay can be defined as a device which is utilized for the protection against certain dangers in electrical transformers of ratings over 500kVA most of them are oil observing in nature. The device protects the transformers from certain dangers such as insulation failure of turns and impulse breakdown of oil. Moreover, it also extends its support from short-circuiting, incipient, and inter-turn etc. This device is having the capability to sense different kinds of faults and shuts the circuitry to avoid damage. The following is a general Buchholz relay diagram.

Features of Buchholz Relay

There are numerous features of Buchholz relay mentioned below.

- It has a consistency against the generation of fake alarms.

- The design of the relay is robust.

- It has a dedicated design for OLTC applications.

- It airtight the transformers.

Basic Working Principle of Buchholz Relay

First of all, let us understand What is the role of the Buchholz relay?

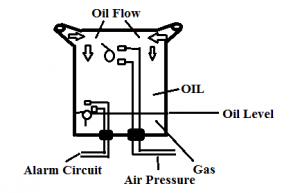

Buchholz relay working principle is based on mechanics i.e. whenever it is activated mechanically. In cases whenever there is an error in the transformer, no matter how small or large, for instance, the error of insulation, the core of transformer halt its working immediately generating CO2 and Co gases. The Buchholz relay gas analysis is undergone. This will roll over the mercury switch hence, dropping the location of the float. The contacts of switches will break immediately. However, on fewer instances because of the outflow of oil in the tank, few air bubbles are building up which make the upper portion of relay’s container to have a drop in the level of oil and alarm appears.

It can also be elaborated that when any fault occurs in an electrical device i.e. transformer there is some heat generated by fault currents. This heat causes decay of the transformer’s oil and bubbles are created which run upwards. These bubbles are relocating oil in the relay which is in a similar manner as to the extent of gas gathered. This dislocation of oil causes higher float for shutting high mercury switch for the generation of an alarm. Therefore, in case even if a small fault occurs the alarm will be generated. In the case of major faults, heat generated is too high and an enormous gas is created. These massive gases are then floating in an upward direction and its motion is enough for tilting of the float of Buchholz relay. The following image is a depiction of Buchholz relay operation.

Construction of Buchholz Relay

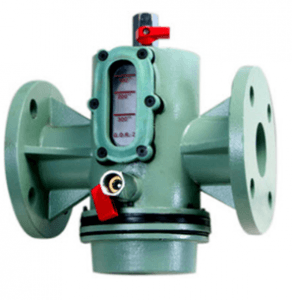

The construction of Buchholz relay is simple and straight forward. There are basically two major elements in the relay. The names of the elements are lower and upper elements. The upper element of the relay consists of a mercury switch which is linked to the float. Whereas, the lower element comprises of mercury switch increased on the hinged flap located over a straight line to the flow of oil. The following is the simple depiction of Buchholz relay construction.

The Buchholz relay advantages and disadvantages are given below in detail.

Advantages of Buchholz Relay

The following are major advantages of Buchholz relay.

- The Buchholz relay is specifying inter-turn errors which are occurring because of heat in the core and is assisting deterrence against major faults.

- The relay is capable to determine the severity of fault even after dismantling of the transformer.

- In the case of major faults, the transformers can easily be isolated through Buchholz relay and accidents can be prevented.

Disadvantages of Buchholz Relay

The following are the major disadvantage of the Buchholz relay.

- The Buchholz relay can only be implemented in transformers and other electrical equipment having absorbed oil.

- The relay is only detecting faults in cases when the level of oil is below.

- The relay is not guarding connecting cables, therefore dedicated protection is required for cables.

- The response time of Buchholz relay is a bit too high.

- 1 second is minimum operation time of this relay.

Applications of Buchholz Relay

Buchholz relay purpose is important in electrical systems and especially in oil absorbed high rating transformers. The following are some major applications of the relay which is famous for its unique nature.

- The bushing of this relay is pierced.

- The relay is used for the insulation failure of the core bolt.

- It can detect the short circuit of windings of the transformer.

- It can also detect the short circuit in between different stages.

- The relay is also feasible to be used in bad and loose electrical contacts.

- It can be utilized at the entrance of the air bubbles in the oil.

- The relay is capable to find the spots where the oil level is reduced because of any leakage.

Testing Procedures of Buchholz Relay

There is numerous Buchholz relay testing procedure and a few famous tests are explained below in detail.

- Leakage Test: The relay can be packed with oil even at 90 degrees Celsius temperature and through the force of its bars it is verified for the outflow for over 30 minutes of time.

- The Electrical Test: The electrical test is composed of the connection to earthen insulation for ensuring for over 1 minute at over 2K volts.

Precautions to take for Installation of Buchholz Relay

The operation of the Buchholz relay is very simple, however, there is a requirement of some special precautions for the installation process of the relay. The following are some of the major precautions which must be considered while installing Buchholz relay.

- The transformer’s float must be checked for the stiffness of air, e.g.immersing in hot oil for making surplus resistance.

- The relay cover and connection pipe must have at least 1.5 to 3 percent slope and must not project to the exterior for making it sure it be clean of gases.

- The connections of the conductor should have paper connections instead of rubber connections to avoid damage from oil.