The shaded-pole motor plays a significant role in low-torque applications. Although these motors have some limitations in terms of efficiency & starting torque, so current technological developments assure an enhanced & more sustainable future for these types of motors. Understanding this motor’s working principles, benefits, and drawbacks with its applications is essential for choosing the right electric motor for a particular application. This article provides brief information on a shaded pole motor, its working, and its applications.

What is a Shaded Pole Motor?

A shaded pole motor definition is; a simple self-starting single-phase induction motor that has one of the poles shaded with the copper ring known as a shaded pole motor or shaded pole induction motor. Here the copper ring is also known as the shaded ring which performs as a secondary winding for this motor. This motor turns simply in one particular way & the reverse direction of this motor is not achievable. The power losses in this motor are extremely high & the motor’s power factor is low. The starting torque of this motor is also extremely low.

The specifications of a shaded pole motor are; the speed of this motor ranges from 1300 to 2000 RPM, the operating voltage is from 220 to 440 V, the Number of phases is single phase, the frequency range is from 50 to 60 Hz, materials used is MS and SS, usage or application is industrial. The shaded pole motor efficiency is very low ranging from 5 to 35% because of the power loss within the shading coil.

Construction

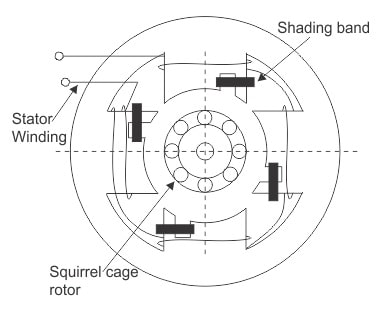

The shaded pole motor construction is very simple because it does not have any brushes, commutators, collector rings, and many more. This motor does not contain any centrifugal switch, so the chances of motor failure are very low. Similar to a normal induction motor, this motor also includes two parts; the stator & rotor. This motor can be designed with two (or) four poles. So the motor speed is inversely proportional to the no. of poles.

The poles of this motor are laminated which means, several material layers are used to make the poles so that the pole’s strength will be increased.

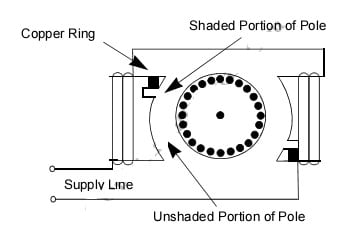

In this motor, the slot is constructed at some space from the edge of the pole. The copper coil which is short-circuited can be arranged within this slot. The part that is coated with the copper ring is known as the shaded part whereas the part that is not coated through the rings is known as the unshaded part.

Construction of Shaded Pole Motor

Stator

The stator of this motor includes a salient pole which means the magnet’s poles are projected in the direction of the motor’s armature. Every pole of this motor is simply excited through its exciting coil. The copper rings shade the loop which is called the shading coil.

Rotor

The rotor used by the shaded pole motor is the squirrel cage rotor. So the rotor’s bars are skewed at an angle of 60º. The skew can be done to obtain a better starting torque. The copper band or shading coil is utilized for shading some segments of the pole to generate the rotary magnetic field. About 1/3 rd segment of the pole is enclosed with a low resistance copper band. After shading a pole through a copper band, two copper coil’s ends are shorted to make a closed circuit.

Working

The shaded pole induction motor working is quite simple. Whenever a single-phase AC supply is provided to its stator winding, then it generates the stator magnetic field. So this magnetic field connects to the shading rings thus, an EMF can be induced within the shading rings.

The shading rings are designed with high-conductivity material like copper which forms a closed loop. In the shading ring, the current starts flowing due to induced EMF within it. So this flowing current also generates a magnetic field that resists the main magnetic field. Therefore, there exists a space displacement within the shaded & unshaded portion of this motor. The space displacement in between both the main & the shaded field is at 90° angle.

This motor generates a rotary magnetic field due to the time as well as space displacement in between the two fields like the main & the shaded portion. The rotary magnetic field turns from the unshaded part to the shaded part of the motor. As a result, this rotary magnetic field simply develops the initial torque within the motor.

Shaded Pole Motor Circuit Diagram

A shaded-pole motor is a type of induction motor that does not contain any start winding although it has one main winding only. So, this kind of motor has some benefits usually cheap, its speed can be simply adjusted with a multi-tap winding (or) varying voltage, this motor is simple to design and can be produced in higher amounts. The typical shaded-pole AC induction motor circuit diagram is shown below.

Shaded Pole Motor Circuit

This kind of motor does not include start winding, thus to start this induction motor, a constant copper loop approximately a small part of each of the motor poles is surrounded by this circuit. The magnetic field in a shaded area of this circuit will cover the field within the unshaded region due to the shaded part of the pole. As a result, the shaft revolving can be attained because of the response of the two fields.

However, this motor circuit has a low starting torque that typically ranges from 25% to 75% of rated torque. The main drawback of this circuit is; it has very low efficiency which is below 20% & the motor running speed ranges from 7% to 10% under the synchronous speed. This type of motor circuit is used wherever the high efficiency, high torque & lot sturdy are not necessary like fans with multi-speed for household purposes.

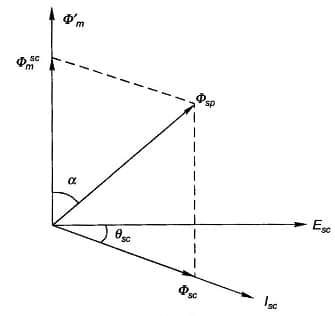

Phasor Diagram

A phasor diagram is a graphical representation of the magnitude as well as the directional relationship between minimum two or above alternating quantities. The shaded pole motor phasor diagram is shown below. In this diagram, we can observe that the net flux within the shaded portion of the pole like Φ̅sp lags the flux ‘Φ̅′m’ within the unshaded part of the pole. So it results in a net torque and that causes the rotor to turn from the unshaded portion to the shaded portion of the pole. Thus, this motor has an exact direction of rotary motion that cannot be reversed.

Phasor Diagram

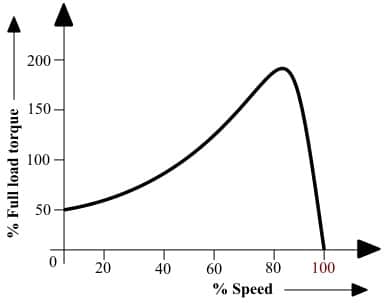

Characteristics

The shaded pole motor’s typical torque-speed characteristics are shown in the following figure. From the following torque-speed characteristics diagram, it is clear that when the speed is initially increased then the torque will be increased and then decreased. Since the Alpha angle value is extremely small thus this shaded pole motor has extremely low starting torque approximately 30 to 50 % of its complete load torque. This motor’s efficiency is also extremely low but, the motor is very reliable, less cost & rugged. Thus, this motor is used only whenever the requirements of starting torque are small.

Characteristics

Generally, a shaded pole motor is a constant-speed motor because its speed will decrease with the load through 10% of a full load. The synchronous speed of this motor is fixed by the supply frequency as well as the no. of poles. For two poles, the slip is about 10% by full load, and the full load speed will be 2000 rpm. Similarly, with a large no. of poles, these motors are simply made for low speeds as 78 rpm for gramophones. When the efficiency is low then a huge part of the current supplies only losses. If this motor mechanically gets slow (or) stalled for long periods then there is no harm to this motor.

Advantages and Disadvantages

The advantages of a shaded pole motor include the following.

- The construction of this motor is rugged.

- These motors are small in size.

- These are not expensive.

- They need less maintenance.

- This motor has less starting torque & power factor.

The disadvantages of shaded pole motors include the following.

- It has less efficiency with stable power loss within the shading coil.

- It has limited starting torque, which it makes inappropriate for heavy loads.

- It is not capable of reversing the motor’s rotation direction without any modifications in design.

- It has limited applications because of its low power factor.

- It has fairly low speed & performance as compared to other types of motor.

- This motor has less efficiency for low speed.

- It is not appropriate for applications with changeable speed

- These motors have less power factor and poor efficiency.

- It has less starting torque thus it is not fine for high-torque applications like electric drills (or) saws.

- It is not used for performance-based applications that require high starting torque like electric vehicles (or) industrial machinery.

Applications

The applications of shaded pole motors include the following.

- Shaded pole motors are used in fans, and small appliances like food processors, blenders, mixers, etc.

- These are used in toys like; electric cars, windup toys, remote-controlled toys, etc.

- These motors are used in portable tools like grinders, drills & saws.

- These are used in refrigerators, AC, etc.

- These are used in electronic devices like; printers, CD players & DVD players.

- This motor is used for hair dryers, cooling fans, desk fans, advertising displays, slide projectors, etc.

- These are used in record players, projectors, tape recorders, photocopying machines, etc.

- These are used mainly for starting electronic clocks & single-phase synchronous timing motors.

- These are used in commercial applications like cooling systems used for display cases & vending machines.

- These are used in medical equipment such as; blood centrifuges.

- These are utilized in automotive applications like cooling fans used for radiators.

- These are applicable in HVAC systems used for air circulation and office equipment like printers & photocopiers.

- They are used in commercial equipment like film projectors, record players & photocopy machines.

Where is the Shaded Pole Motor Used?

Shaded pole motor is used for hair dryers, toys, desk fans, slide projectors, cooling fans, air conditioners, advertising displays, etc.

Are Shaded Pole Motors Efficient?

The shaded pole induction motor efficiency is very low approximately ranging from 5%. to 35% because of power loss within the shading coil.

Can a Shaded Pole Motor be Reversed?

This motor turns in one specific direction only the motor’s reverse movement is not achievable.

How Does s Shaded Pole Motor Fail?

This motor will fail because of wrong wiring, short circuit, Low voltage; wear of the bearing, the rotor bar disconnection, etc.

What is the Highest Hp for a Shaded Pole Motor?

The HP range of these motors ranges from 1/50 HP to 1/20 HP and its continuous torque will range from 30 in-lbs to 150 in-lbs.

How Does a Shaded Pole Motor Start?

This is a motor is a self-starting motor where one of the poles of this motor is shaded through the copper ring.

Which Portion of the Pole in the Shaded Pole Motor is Bigger?

The bigger pole is the unshaded part in the shaded pole motor.

What Determines the Speed of a Shaded Pole Motor?

The speed of the shaded pole motor determines the magnitude of the rotating velocity of the shaft and the number of total revolutions for each unit of time.

Thus, this is an overview of the shaded pole motor or shaded pole induction motor, construction, working, circuit, advantages, disadvantages, and its applications. This motor is one of the types of single-phase AC induction motor which has simplicity & reliability. These types of motors are used commonly in different small devices and appliances like fans, small pumps & refrigerators.

These motors have shading coils on the pole faces of the motor, which provides the primary phase shift required for the rotation of the motor without using complex starting mechanisms. These motors are not expensive and the starting torque which is developed by these kinds of induction motors is extremely low. The losses of this motor are high & the power factor of this motor is very low. Thus, the efficiency of this motor is also extremely low. Because of these reasons, these motors are designed in small sizes only with 40W or below power rating. Here is a question for you, what is an induction motor?