An induction motor is a type of electric motor that uses AC, pushed by a magnetic field that turns. These motors are designed with a rotor, a stator & coil that changes energy from electrical to mechanical with electromagnetic induction. Induction motors are very flexible, efficient, and very simple to design, and allow them to be used with almost any electrical load. There are mainly two kinds of induction motors exist like; Squirrel cage & slip ring induction motor. This article provides brief information on the squirrel cage induction motor, construction, working, and its applications.

What is Squirrel Cage Induction Motor?

A Squirrel cage motor is a sub-type of induction motor, that harnesses electromagnetism to produce motion. As the name suggests, it is derived from its rotor design because it resembles a squirrel cage wheel. This is one of the most frequently used types of induction motors, used widely in various commercial & industrial applications. The shaft of this motor is connected simply to the rotor which looks similar to a cage & it works on the electromagnetism principle. Thus it utilizes the electromagnetic induction effect for converting the energy from electrical to rotational.

Squirrel Cage Induction Motor

Squirrel Cage Induction Motor Construction

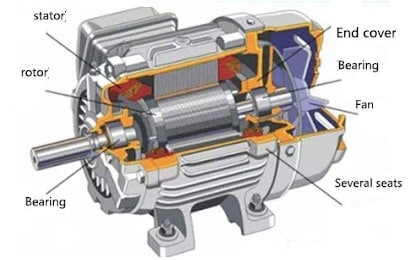

A squirrel cage induction motor is constructed with a stator, rotor, fan, bearings and end cover which are discussed below.

Squirrel Cage Induction Motor Construction

Stator

In the squirrel cage induction motor, the stator is the external component which has a 3-phase winding including a core & metal housing. The windings of this motor are arranged in such a way that they are 120o apart from within space mechanically & electrically. These are either delta-connected or star-connected. The winding of this motor is mounted above a stator to provide a less reluctance path by A.C current for generated flux. Generally, the insulation between the windings is varnish (or) oxide-coated.

Rotor

The rotor of this motor is a rotary part that provides mechanical output for a specified quantity of electrical energy. The output of this motor is mentioned in horsepower on the nameplate. Almost all induction motors have squirrel cage rotors due to their simple construction and robustness. The rotor in this motor is a cylindrical core that is laminated to avoid power losses. This motor’s rotor is made up of copper bars or aluminum which are arranged parallel to each other & all the bars are short-circuited through end rings. Both the rotor conductors & end rings will form a closed circuit. The rotor core here is laminated to avoid power losses from hysteresis & eddy current.

Fan

A fan of the squirrel cage induction motor is connected to the reverse side of the rotor to supply heat exchange. Thus it maintains the motor’s temperature under a limit.

Bearings

Bearings of this motor are provided simply as the base mainly for the motion of the rotor & the bearings maintain the smooth revolution of the motor.

End Cover

The end cover in this motor protects the end of the exposed shaft and avoids accidents. These have very good resistance to most chemicals. They can withstand up to 100 °C operating temperatures. These covers are very simple to install and most roller-bearing units accommodate particularly designed end covers.

How do Squirrel Cage Motors Work?

Squirrel induction motor works on the electromagnetism principle. Whenever a three-phase AC is supplied to the stator winding then it generates an RMF (rotating magnetic field). This RMF has a speed known as synchronous speed. The rotating magnetic field can cause voltage which is induced within the rotor bars so that short circuit current can flow throughout the rotor. So, a self-magnetic field can be generated and it interacts through the stator field. At this time, the rotor field begins opposing its cause according to the principle. Once the RMF catches the moment of the rotor the rotor current will drop to zero. After that, there would be no relative moment between the rotor & RMF.

Therefore, the zero tangential power is experienced through the rotor & decreases for a minute. After the rotor moment reduction, the rotor current can be induced again through the reform of relative motion between the RMF and the rotor. So the tangential power of the rotor for the revolution is restored & begins by following the rotating magnetic field. The rotor in this case maintains a stable speed, which is below the RMF & synchronous speeds. At this time, the variation between the RMF speed & the rotor is simply measured in the slip form. The final rotor frequency can be attained by the development of slip & supply frequency.

Features

The features of the squirrel cage induction motor include the following.

- Speed: This motor is operated normally at a constant or synchronous speed.

- Starting Current: Squirrel cage induction motor uses a high starting current to provide low starting torque.

- The Rotation Direction: These motor’s rotation direction can be upturned if you exchange two power lines out of three.

- Slip: It is a measure of the variation between the rotating magnetic field speed & the rotor speed. The rotor current frequency = slip × frequency supply.

- Power Factor: It is the ratio of actual and apparent power, expressed within percentage. When an electric motor is run at no load then PF is low. Similarly, when the electric motor operates at full load then PF is high.

Specifications

The specifications of the squirrel cage induction motor include the following.

- The power range is from 0.25 to 120 HP.

- Its version is 380 to 415 V, AC @ 50 Hz

- Its speed is 2, 4, 6, 8, and 10 Pole.

- It is enclosed with a fan for cooling purposes.

- Frame size is 56 to 280M.

- The ambient temperature is 50°Centigrade.

- Insulation is Class F.

- The combined variation is 10 %.

- The degree of protection is IP-55

- It has a deep frictional groove ball bearing.

- It has high-temperature Li complex grease (155°C).

- Foot mounted based on IS 1231 (B3), Flange mounted according to IS 2223 (B5), Foot cum Flange mounted (B35), and Face Mounted (B14.

Classification of Squirrel Cage Induction Motor

Squirrel cage induction motors are available in different types based on their electrical characteristics like class A, class B, class C, class D, class E, and class F respectively which are explained below.

Class A Type

Class A type squirrel cage induction motor is the most popular type of motor which uses squirrel cages with fairly low reactance & resistance. Generally, this motor’s blocked-rotor current is above six times the rated complete load current. The starting torque with full load voltage for smaller sizes & low number of poles is almost twice the complete load torque. Similarly, the starting torque for larger sizes & more poles is simply a bit above full load torque.

The pullout torque in this type is 200 to 300 percent always for the full-load torque &it happens at a low slip. The starting torque is equivalent to the rated torque mainly for larger motors & is about 200 percent above the rated torque of the smaller motors. Class A squirrel cage induction motors are used which have fewer inertia loads so that they can speed up in less time like in compressors, conveyors, fans, pumps, etc.

Class B Type

This type of squirrel cage induction motor generates a similar starting torque to the class A type. These motors are started at full load by developing regular starting torque with quite a low starting current.

This induction motor’s blocked-rotor current including full voltage is normally five times the full load current. In this motor, the rotor bars are thin and located deeper to get high reactance at the beginning. The pullout torque of this motor is higher or equivalent to 200 percent always of the rated load torque. Although, it is below the class A type because it has improved rotor reactance. The rotor slip for this motor is still quite low below 5 percent at full load.

Class B-type squirrel cage induction motors are used wherever the load has high inertia like; machine tools, large fans to drive electric generators, and centrifugal pumps. As compared to class A, these types of motors are mostly preferred due to their lower starting-current necessities.

Class C

Class C type squirrel cage induction motor is normally double squirrel cage type. This motor’s blocked-rotor current & slip with full voltage is almost similar to that of the class B type. Generally, these motor’s starting torque including applied full voltage is three times to full load torque. In this type of design, the full load torque & the starting torque is Up to 250 percent. The pullout torque is below as compared to the Class A type.

Class C motors are expensive as compared to Class A & B because these are built with double-cage rotors. Class C squirrel cage induction motors are used for high-starting-torque loads like; pumps, conveyors & compressors. These motors are applicable wherever adequately high starting torque with decreased starting voltage is necessary like; crushers, large refrigerators, compression pumps, textile machinery, equipment in woodworking, and many more.

Class D Type

In class D type squirrel cage induction motor, the high resistance rotor bars are used to provide high starting torque including low starting current. As compared to class B & C motors, these motor’s blocked rotor current including full applied voltage is the same. Full load slip in this motor may change from 5% to 20% based on application. In this motor, thin rotor bars are utilized to decrease the leakage flux & enhance the useful flux to provide high starting torque including low starting current.

In class D type, the high rotor resistance moves the peak torque to an extremely low speed. It is even achievable at zero speed for the maximum torque to happen in this type of design. In this type of motor, full load slip is quite high because of the high rotor resistance. These induction motors are used wherever very high starting torque is necessary like; shearing machines, bulldozers, foundry equipment, stamping machines, punch presses, laundry equipment, metal drawing equipment, etc.

Class E Type

Class E-type squirrel cage induction motors have quite low slip at rated load, extremely low starting torque, and normal starting current. The starting current may be high for induction motors >5kW rating, thus they need a compensator (or) resistance starter. In this motor, a resistance starter or compensator is utilized for controlling the starting current.

Class F Type

Class F-type squirrel cage induction motors with low starting torque and low starting current can start at full voltage. The rotor of this motor is designed in such a way that it provides high reactance at the beginning. As compared to class B and class C types, these motor’s blocked rotor current & full load slip including full applied voltage are the same. In this motor, the starting torque including full applied voltage is almost 1.25 times the complete load torque.

Difference between Squirrel Cage and Slip Ring Induction Motor

The differences between squirrel cage and slip ring induction motor are discussed below.

| Squirrel Cage Induction Motor | Slip Ring Induction Motor |

| The induction motor using a squirrel cage-type rotor is called the squirrel cage motor. | The induction motor using a slip ring rotor is called the squirrel cage motor. |

| This motor is also known as a cage motor. | This motor is also known as the Phase wound rotor. |

| Its construction is simple. | Its construction is complicated. |

| In this motor, is not achievable to include any external resistance. | In this motor, is possible to include external resistance to the rotor. |

| The resistance starter of the rotor cannot be utilized. | The resistance starter of the rotor can be utilized. |

| It has a low starting torque. | It has high starting torque. |

| Brushes are not available in this motor. | Brushes are available in this motor. |

| It needs less maintenance. | This motor needs frequent maintenance. |

| This motor has a low copper loss. | It has high copper loss. |

| The speed control is not possible in this motor. | The speed control is possible in this motor. |

| It has a high power factor. | It has a low power factor. |

| These are less costly. | These are costly. |

| Its starting current is high. | Its starting current is low. |

| The efficiency of this motor is high. | The efficiency of this motor is low. |

| It is used in lathe machines, blowers, profiting machines, fans, etc. | It is used in hoists, elevators, and cranes wherever high torque is necessary. |

Advantages and Disadvantages

The advantages of squirrel cage induction motor include the following.

- Squirrel cage induction motors are low-cost.

- These motors need less maintenance because there are no brushes or slip rings.

- It has good speed regulation.

- It has high efficiency in converting energy from electrical to mechanical.

- These motors have better heat regulation.

- These are small & lightweight.

- There is no risk of sparking because there are no brushes.

- The Squirrel cage motor is reliable and robust.

- It is easy to operate & maintain.

- It is a cost-effective induction motor.

- It has a rugged construction.

- This motor needs less conductor material, so copper losses in this motor are low.

- These motors are better cooled as compared to other induction motors.

- This motor operates at an almost constant speed, high overload capacity & works at a better power factor.

The disadvantages of squirrel cage induction motors include the following.

- These motors have very poor speed control.

- These motors are energy efficient when running at full load current.

- They consume more energy on startup.

- These are more sensitive to fluctuations within the voltage supply. Once the voltage supply is decreased, this motor draws a huge current.

- These induction motors have high starting current & poor starting torque.

- The speed in this motor cannot be controlled easily.

- This motor has more sensitivity whenever fluctuation takes place in the voltage supply.

Applications

The applications of squirrel cage induction motor include the following.

- Squirrel cage induction motor is used commonly in various industrial applications where this motor should maintain a stable speed, and be self-starting (or) there is a need for less maintenance.

- These induction motors are used commonly in centrifugal pumps, machine tools, industrial drives, large blowers, fans, centrifugal pumps, lathes, etc.

- These motors are used to drive conveyors, air compressors, crushers, small hoists, punch presses, reciprocating pumps, shears, bulldozers, large refrigerating machines, mixers, and many more.

- Squirrel cage induction motor is applicable in printing equipment for continuous speed work like; moving platens, guillotines, other small devices, etc.

- It is used within commercial buildings, ventilation systems, manufacturing machinery, elevators, hydroelectric power plants, wind turbines, etc.

- These motors are used in electric vehicles because of their durability & high efficiency.

- These are used in home appliances like air conditioners, washing machines, refrigerators, etc.

What is the use of a squirrel cage induction motor?

A squirrel cage induction motor is used for continuous speed work in printing equipment like moving platens, guillotines, etc.

Why is the speed of a squirrel cage motor fixed?

The squirrel cage motor speed is fixed because the variation in speed from no load to complete load is extremely small.

Why squirrel cage rotor is skewed?

The squirrel cage rotor is skewed to reduce noise and stabilize torque fluctuations that might affect some speeds because of interactions through the pole parts of the stator.

Thus, this is an overview of the squirrel cage induction motor, construction, working, types, differences, advantages, disadvantages, and applications. These motors are versatile, efficient, and reliable, making them the best choice for being widely used in various domains. The main benefit of these induction motors is that their torque speed characteristics can be changed easily by simply changing the bar’s shape. These motors are reliable, self-starting, and convenient in many areas. These induction motors have made their pathway in several application areas in electrical engineering because of their robustness & versatility. Here is a question for you, what are the different types of induction motors?