The wire gauge is a significant factor in selecting an electrically conductive wire for a specific application but, the suitable gauge mainly depends on different factors. Thicker wires are mainly used in higher amperage rating circuits for handling the load very efficiently & avoid extreme buildup of heat. Using very thin wires within the particular circuit amperage can lead to wire malfunction or electric fires. These issues can be overcome by determining the whole system amperage by simply calculating the effects of the planned load, circuit length, and load connected. So a suitable wire is chosen depending on this calculation to ensure secure & very efficient operation. This article provides brief information on a wire gauge, its types, and its chart with applications.

What is Wire Gauge?

A gauge that is used to measure wire diameter (cross-sectional area) in the metrology field of round, nonferrous, solid and electrically conducting wires is known as a wire gauge. This determines how much current can flow throughout an electric wire without being injured which is known as ampacity and also it determines the resistance of the electrical wire with its weight for each unit of length.

The wire ampacity mainly depends on different factors like size & insulation. It is significant to ensure that the ampacity of the wire is not exceeded while connecting it to a circuit. Insulation plays a key in deciding the ampacity of wire because it can resist varying heat levels, which can develop the relative ampacity of wire. Usually, a lower wire gauge has higher-rated ampacity as compared to a high gauge wire because the larger wire diameter simply allows more current to carry.

The conductor of a wire must be improved to decrease resistance for optimum transmission. So wire gauges help the users recognize the current-carrying ability of electrical wires.

Wire Gauge

How Do You Determine Wire Gauge Size?

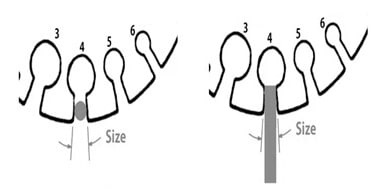

The wire gauge size can be determined by simply measuring the wire diameter. The most common technique used to measure the size of a wire gauge is to utilize a wire gauge tool. This is a small tool including a set of increasing size openings. The wire is placed into a suitable opening & the wire size is decided by the opening of the wire that it fits into. Another technique used to determine the gauge size is to utilize a micrometer. This is a precision measuring device that measures the wire’s diameter with high accuracy.

The diameter of the wire gauge determines how many amperes a wire can perform without overheating. If a wire gets overheated, then the insulation of the wire could melt off & cause a fire. So it is significant to identify which wire gauge size is required for the wire utilized to connect appliances, outlets & switch boxes for a breaker box.

Determine Wire Gauge Size

Wire Gauge Selection

The wire gauge selection can be done based on different factors which are discussed below.

Diameter

Wire gauge diameter ranges from low diameter to high diameter. For instance, the diameter of AWG 4 wire gauge is 0.2043 inches and AWG 40 wire gauge is .0031 inches. Whenever the gauge reduces by six levels then the diameter doubles. The cross-sectional area of wire doubles each time then it goes down to three levels.

Feet per Pound

Feet per pound is the number of feet of wire required to achieve a single pound within weight. For instance, AWG 4 wire needs 7.918 feet whereas AWG 40 needs 34.364 feet.

Resistance

The electrical resistance of wire mainly depends on its thickness & length. Longer wires give higher resistance whereas shorter wires give lower resistance. The resistance of thicker wire has a smaller resistance as compared to thinner wire. For instance; AWG 4 wire at 25° C has a.2485Ω of resistance for 1000 feet whereas AWG 40 wire has 1079Ω resistance for 1000 feet.

Current Capacity

Current capacity refers to a measure of the sum of current a wire carries securely. When AWG 4 low gauge wires are thicker, then they can hold more electrons as compared to AWG 40 higher gauge wires.

Chart

The wire gauge chart is shown below which shows very detailed information about each conductor’s property.

| AWG | Diameter(mm) | Diameter (inches) | Max Current (Amps) | Area (mm2) | Maximum Frequency | Resistance(Ohms/km) | Resistance (Ohms/100ft) |

1/0 | 8.27 | 0.32 | 150 | 53.6 | 250Hz | 0.33 | 0.09 |

2/0 | 9.3 | 0.37 | 190 | 67.5 | 200Hz | 0.26 | 0.08 |

| 3/0 | 10.41 | 0.41 | 240 | 85 | 160Hz | 0.20 | 0.06 |

| 4/0 | 11.67 | 0.46 | 302 | 107 | 125Hz | 0.160 | 0.05 |

| 1 | 7.4 | 0. 29 | 119 | 42.5 | 326 Hz | 0.407 | 0.12 |

2 | 6.5 | 0. 26 | 94 | 33 6 | 410 Hz | 0.512 | 0.15 |

3 | 5.8 | 0. 22 | 75 | 26.8 | 500 Hz | 0.655 | 0.19 |

| 4 | 5.19 | 0. 21 | 60 | 21.2 | 650 Hz | 0.82 | 0.25 |

| 5 | 4.62 | 0. 19 | 47 | 16.8 | 810 Hz | 1.02 | 0.32 |

6 | 4.02 | 0. 17 | 37 | 13.4 | 1100 Hz | 1.30 | 0.39 |

7 | 3.07 | 0. 14 | 30 | 10.5 | 1300 Hz | 1.63 | 0.50 |

| 8 | 3.27 | 0. 12 | 24 | 8.04 | 1650 Hz | 2.06 | 0.62 |

| 9 | 2.90 | 0. 11 | 19 | 6.64 | 2050 Hz | 2.06 | 0.08 |

10 | 2.06 | 0. 10 | 15 | 5.27 | 2600 Hz | 3.28 | 0.99 |

Types of Wire Gauge

There are different types of wire gauges which are discussed below.

14-gauge Wire

If the thickness of a gauge of a wire is 14 then it is known as 14-gauge Wire. These wires are represented by the number 14. These types of 14-gauge wires are used for light fixtures, lights, lighting circuits through 15 Amps & household receptacles.

14-gauge Wire

- The diameter of this in inches is 0.06.

- The diameter of this in mm is 1.62.

- The area of this in mm^2 is 2.08.

- The resistance of this in Ohms/100ft is 2. 52.

- The resistance of this in Ohms/km is 8.29.

- The maximum current of this in Amperes is 5.9.

- The maximum frequency of this is 6700 Hz.

- The recommended 80% Wattage load for 14-gauge wire is 1440 watts (120 volts)

- Its maximum Wattage load is 1800 watts (12V).

12-gauge Wire

If the thickness of a gauge of a wire is 12 then it is known as 12-gauge Wire. These wires are represented by the number 12. These types of 12-gauge wires are used for common wiring in residential areas like; small appliances, light fixtures, household receptacles, etc.

12-gauge Type

- The diameter of this in inches is 0.08.

- The diameter of this in mm is 2.05.

- The area of this in mm^2 is 3.31.

- The resistance of this in Ohms/100ft is 1.58.

- The resistance of this in Ohms/km is 5.20.

- The maximum current of this in Amperes is 9.3.

- The maximum frequency of this is 4150 Hz.

- The recommended 80% Wattage load for 12-gauge wire is 3840 watts (240V) & 1920 watts (120V).

- Its maximum Wattage load is 4800 watts (240 V) & 2400 watts (120 V).

10-gauge Wire

If the thickness of a wire gauge is 10 then it is known as 10-gauge Wire. These wires are represented by the number 10. These types of 10-gauge wires are used in large household appliances which include; clothes dryers and window AC units, etc.

10-gauge Type

- The diameter of this in inches is 0. 10.

- The diameter of this in mm is 2.58.

- The area of this in mm^2 is 5.26.

- The resistance of this in Ohms/100ft is 0.99.

- The resistance of this in Ohms/km is 3.27.

- The maximum current of this in Amperes is 15.

- The maximum frequency of this is 2600 Hz.

- The recommended 80% Wattage load for 10-gauge wire is 2880 watts (120V), 5760 watts (240V).

- Its maximum Wattage load is 3600 watts (120V), 7200 watts (240V).

8-gauge Wire

If the width of a wire gauge is 8 then it is known as 8-gauge Wire. These wires are signified with the number 8. These types of 8-gauge wires are used in central AC, Electric ranges, etc.

8-gauge Type

- The diameter of this in inches is 0.12.

- The diameter of this in mm is 3.2.

- The area of this in mm^2 is 8.3.

- The resistance of this in Ohms/100ft is 0.62.

- The resistance of this in Ohms/km is 2.06.

- The maximum current of this in Amperes is 24.

- The maximum frequency of this is 1650 Hz.

- The recommended 80% Wattage load for 8-gauge wire is 7680 watts (240V).

- Its maximum Wattage load is 9600 watts (240 V).

6-gauge Wire

If the width of a wire gauge is 6 then it is known as 6-gauge Wire. These wires are signified with the number 6. These types of 6-gauge wires are used in large household appliances like; electric furnaces, central AC, etc.

6-gauge Type

- The diameter of this in inches is 0.16.

- The diameter of this in mm is 4.11.

- The area of this in mm^2 is 13.3.

- The resistance of this in Ohms/100ft is 0.39.

- The resistance of this in Ohms/km is 1.29.

- The maximum current of this in Amperes is 37.

- The maximum frequency of this is 1100 Hz.

- The recommended 80% Wattage load for 8-gauge wire is 10560 watts (240V).

- Its maximum Wattage load is 13200 watts (240V).

Uses/Applications

When each wire gauge holds different electrical & physical properties, then they are suitable normally for several purposes. Thinner wire gauges are normally used in lightweight applications whereas thicker wire gauges are normally used for heavy-duty applications.

- Wire Gauge 18 is used in low-voltage lighting, doorbells, Thermostats & cords

- Wire Gauge 14 is used in devices, 15-amp lighting circuits, office outlets & lighting fixtures.

- Wire Gauge 4 is used in large heaters & furnaces.

- 3/0 AWG is used for wiring 200 Amp residential service.

- Wire Gauge 6 is used in kitchen cooktops & ranges.

- Wire Gauge 16 is used in light-duty extension cords.

- Wire gauge 8 is used in Small ovens & AC units.

- Wire Gauge 12 is used in small AC units, bathrooms, kitchens & residential outlets.

- Wire Gauge 10 is used in clothes dryers, washing machines, water heaters, small electric ovens & large AC units.

- 2 AWG, 4 AWG & beyond are used mainly for larger loads which include; AC units, subpanels & hot tubs.

What is the Gauge of a Wire?

The gauge is a significant specification of a wire.

What Does AWG Mean in Wire?

The AWG (American Wire Gauge) is one of the most famous standards for sizes of wire.

What Gauge is Standard Electrical Wiring?

The 10, 12, or 14 gauges are the most common and standard gauges. When the gauge number is higher, then the wire’s diameter will be smaller.

How do you use a Wire Gauge Tool?

A wire gauge tool helps determine the width of the wire you are working with.

What Tool is Used to Measure Wires?

A micrometer tool is used to measure the wire diameter if you need to verify the accuracy of your measurement.

Why is the Gauge Measured Backwards?

It can be measured “backward” because it was defined with imperial units. So there is no proper method for measuring small things with imperial units, thus inverse fractional scales were utilized.

How Does Gauge Size Work?

The sizes of a Wire gauge are signified through numerical values. If the number allocated to a wire is lower, its diameter will be larger and if the allocated number is higher then its diameter will be smaller.

Thus, this is an overview of wire gauge, selection, chart, and its uses. These wires are accessible in different thicknesses which are known as gauges. The wire gauge determines the capacity of the wire to conduct amperes without overheating. If any wire overheats, then it melts its insulation & causes fire potentially. So, it is essential to decide the suitable gauge size for wires utilized for connecting outlets, switch boxes & appliances to a breaker box. Here is a question for you, AWG stand for?