Due to the improved control structures, hardware and other automation systems in traction elevator systems, most of the manufacturers are producing energy-efficient elevators. Regenerative drive system in elevator is a remarkable advancement in these energy efficient elevators. For mid and high-rise buildings, traction or cable-driven type of elevators are perfectly suitable compared with the electromechanical relays-based elevators and hydraulic elevators. This article is not intended to give an advanced concept about this topic, but to give an idea of ‘how elevators work’.

Due to the improved control structures, hardware and other automation systems in traction elevator systems, most of the manufacturers are producing energy-efficient elevators. Regenerative drive system in elevator is a remarkable advancement in these energy efficient elevators. For mid and high-rise buildings, traction or cable-driven type of elevators are perfectly suitable compared with the electromechanical relays-based elevators and hydraulic elevators. This article is not intended to give an advanced concept about this topic, but to give an idea of ‘how elevators work’.

Types of Elevators

An Elevator is a vertical transport system that carries people or goods between the floors of building safely and efficiently. There are different types of elevators:

- Hydraulic Elevators

- Pneumatic Elevators

- Cable driven or traction Elevators

Types of Elevators

In an elevator, car is raised or lowered within several floors of a commercial and residential building. Depending on the load and the area of application, these elevators are installed with rated capacity. Hydraulic elevators are simple and effective in which the force required to move the car is low compared to the other elevators, but still their use is limited for certain stories high buildings such as 4 to 5 owing to the working ability of these elevators.

Compared to traditional elevators, pneumatic-vacuum elevators are environmental friendly, easy to maintain, install and operate. And, compared to hydraulic elevators, pneumatic vacuum elevators require high pressure to move the car- and, in addition, their usage too is limited for a limited number of storied building. These elevators that run based on air pressure are safe and popular over the past several years for two to three-storied buildings.

Nowadays buildings are constructed to greater heights and with the invention of traction electric elevators – they are commonly used in such buildings. Top speed, smooth ride quality and better elevation are the basic characteristics of these elevators. Let us see in brief about ‘how an elevator works’.

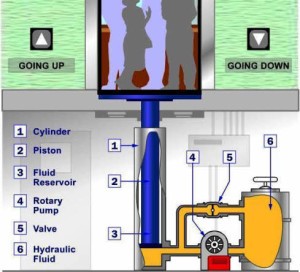

How Hydraulic Elevators Work?

The below figure shows the working of a hydraulic elevator wherein hydraulic fluid with a pumping system moves the elevator car up and down. In this type of elevator, a tank or fluid reservoir supplies hydraulic oil and the pump forces this oil through a least resistance path and returns it to the reservoir when the valve is opened. So when the valve is closed, the pressurized oil created by the pump pushes the piston upside so that the car moves in the upward direction. And when the valve is opened, the fluid returns back to the tank, and hence the piston moves downwards.

Hydraulic Elevators

If the elevator reaches the correct floor, the elevator-control system sends the signals to a motor driver, which stops the motor, and then the pumping of fluid is halted at that position. While lowering, the car stays on exact floor by controlling the signals to the valve mechanism to open or close the valve. This is how the hydraulic system is operated for lifting and lowering the elevator car.

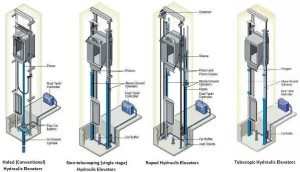

Due to a special type of fluid in this system, the force required to push the piston is very less. This is an advantage of it, but, in order to elevate the car, the piston length required should be more. In other words, if the building height is more, the piston length required should also be longer. This requires an in-depth buried structure for high-storied buildings that’s why these are limited for high-storied buildings. Different types of hydraulic elevators are shown in the below figure.

Different Types of Hydraulic Elevators

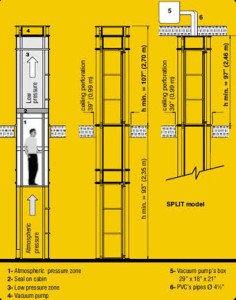

How Pneumatic Elevators Work?

Pneumatic Elevators

This type of elevator consists of exterior cylinder which is transparent self-supporting tube consisting of modular sections, which can be easily fitted into one another. The roof of this tube is made up of steel that ensures air-tight closures with suction inlets and valves. An elevator car runs inside this cylinder, and the head unit on the top cylinder contains turbines, valves and controllers to control the movements of this elevator.

The vacuum pump of the elevator generates higher and lower atmospheric pressures above or below the elevator car, which cause to move the elevator upwards and downwards. As shown in the below figure, the car is lifted high by a higher atmospheric pressure below the car and a lowered air pressure above the car.

When the valves in the low-pressure chamber allow air into it – this causes to lower the car. These valves are also involved in controlling the speed of the car in a desired level. But, this type of elevator cannot build enough pressure to push the car to more than 3- 4 storied high building. That’s why these elevators find limited usage.

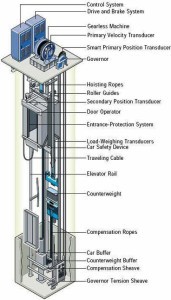

How a Cable Driven or Traction Elevator Works?

Cable Driven or Traction Elevator

This is a typical and most popular type of elevator consisting of a few numbers of hoisting ropes or steel cables which run over a pulley connected to an electric motor. This elevator can be a geared or gearless-traction elevator. In this type of elevator, five to eight wire cables or hoisting cables are attached to the top of the elevator car by wrapping around it on sheaves at one end, and the other end is attached to a counter weight that moves up and down on its guiderails. This counter weight is equal to the weight of the car plus half of the maximum passenger load in that car. This means, during the lifting operation, it needs power for the extra passengers in the car, and, the rest of the weight is balanced by the counter weight.

Whenever the control system attached to the elevator drives the motor in the forward direction, the sheaves also turn around causing to move the car elevator upwards, and then stopping in the desired floor wherein the car is balanced by the counter weight. For the downward movement of the car, reverse happens through a rotating motor via a control mechanism. Some of the elevators use motors with four-quadrant operation to save the energy in regenerative mode. Due to high speeds and high-rise capabilities, these types of elevators are found in many of the applications of lifts and escalators.

Elevator Circuit Diagram

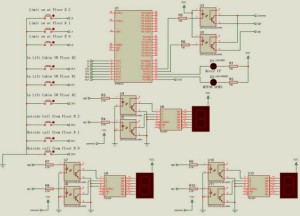

For a better understanding of an elevator operation, a simple practical circuit is illustrated here using a microcontroller for the readers who are interested in developing microcontroller projects. In the below circuit, switches are connected to the various ports of the microcontroller on three floors and also in the car elevator. Each floor’s display is depicted in seven-segment displays which are interfaced to the microcontroller unit.

Elevator Circuit Diagram

The indications of the upward and downward directions of the elevator are indicated using Light Emitting Diodes. For moving the elevator, a motor is driven through a transistor which is not given in the circuit. The Microcontroller is programmed logically in such a way that for the corresponding input switch, it rotates the motor and also drives the seven-segment display and LED display.

This is how elevators work based on hydraulic, pneumatic and traction electric principles. Thanks for your keen attention on reading this article and we believe that the given content might have offered you some interesting insights while reading it. You can also write to us in the comment section for any doubts about this topic, particularly in the circuit demonstrated at last.

Photo Credits: