An electrical generator is a machine that converts mechanical energy into electrical energy. It works on the principle of electromagnetic energy conversion. When a mechanical domain is given to the machine it develops a magnetic field that is further converted into electrical energy. Initially, mechanical energy to the machine is given by a prime mover. Due to this input current passes through the windings which develop the magnetic field. This magnetic field is utilized to convert mechanical energy to electrical energy. Depending upon the type of input given it is classified into two DC and AC respectively. In this article, we shall discuss what is a DC generator, construction, how it works, how emf is induced, characteristics and applications.

What is a DC Generator

Definition: It is an instrument that changes mechanical energy into electrical energy which gives its output as Direct current. It is commonly used by householders and also by offices in the case of power shutdown.

Construction

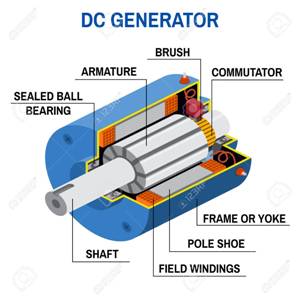

It consists of a frame called the Yoke, pole core, armature core, armature windings, commutator, brushes, and bearings. The yoke is the outer part of the machine that is used for protecting it against environmental issues. Hence, protecting shield for the machine. It is also used as a mechanical support for the pole core. In small generators, Yoke is made of Cast Iron whereas, in large generators, the yoke is made of cast steel.

Field magnets consist of pole core and pole shoe and these magnets get magnetized when current is flown through the winding. The field winding rests on the pole shoe which is responsible for the production of a magnetic field. Field magnets are responsible for expanding the flux throughout the airgap. Due to the large space available inside the machine, the reluctance of the magnetic path is less. Armature provides space for the armature conductors to be housed on it. It is normally made of some circular sheet laminations of 0.5mm thickness. The figure below depicts how armature laminations are punched.

Armature windings are employed on the armature of a machine. Usually, armature core outer diameter is punched at regular intervals to house the armature conductors. A commutator consists of some segments made of mics. It is used for accumulating current from the armature conductors and then, it converts the AC to unidirectional current. Brushes are housed inside the brush holders and are rectangular. These are made of either carbon or graphite and used to accumulate current from the commutator. The schematic diagram of the machine is shown in the figure below.

Parts of the Machine

Working

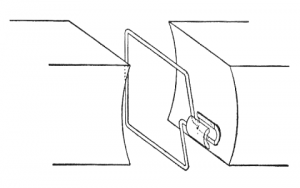

Consider a simple loop generator in which a conductor is made to rotate in between permanent magnets. The figure which depicts the single loop generator is shown in the figure below.

Single Loop Generator

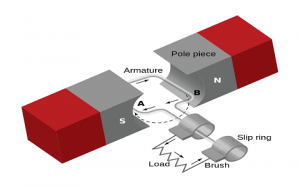

Due to the permanent magnets, the magnetic field is developed inside the generator. When the conductor is rotated inside this magnetic field, it cuts these lines of magnetic flux to produce an EMF. This induced EMF causes the current to flow inside the single loop. The working of the machine is shown in the figure below.

Working Diagram

The single loop conductor is classified into A, B, C and D as shown in the figure. As the loop continuously rotates inside the magnetic field an AC will be generated. When the side AB of the loop is perpendicular to the magnetic field maximum amount of EMF will be induced but it is vice-versa when AB is parallel. The amount of EMF induction is directly proportional to the rate of magnetic flux. Therefore, an alternating current is developed inside the generator initially. But, to the implementation split rings the alternating current is changed to direct current. The Initial current induced inside the generator is shown in the figure below.

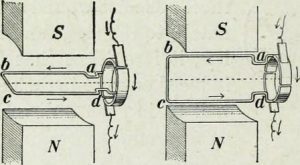

How Machine Works

The split rings segments with brushes are attached to either end of the loop. The split rings are divided into two-segment which are laminated from each other by Mica. The side AB is connected to the split ring segment ‘a’ and the side CD is connected to the segment ‘b’. As the loop rotates, for every half a rotation the segments of split ring interchange from ‘a’ to ‘b’ and for next cycle ‘b’ to ‘a’. Therefore, this action makes possible for the split ring to generate a unidirectional in the single loop. This process of conversion of AC to unidirectional current is known as commutation.

How EMF is Induced

This works on the principle of Faraday’s law of Electromagnetic Induction. It states that whenever a magnetic flux is cut by the conductors an EMF will be induced. Similarly, an EMF is induced in the generator due to the rotation of conductors inside the magnetic field.

EMF Equation

The emf induced is expressed by the equation

E = ФZN/60 . P/A

where

E = Induced EMF,

Z = number of conductors,

A = number of parallel paths,

P = number of poles,

N = speed in r.p.m, and

Ф = Flux per pole in wb (weber)

The frequency of the machine can be found by

f = PN/120

where

f = frequency of the system in HZ,

p = number of poles, and

N = speed of armature in r.p.m.

Armature Reaction of DC Generator

- The armature is the type of winding that is placed on the rotor in these machines. As the rotor rotates an emf will be induced in it when experienced by an electromagnetic field.

- The armature reaction is the opposite of the magnetic field developed by the permanent magnets and the magnetic field developed by the armature flux.

Please refer to this link to know more about DC Generator MCQs

Characteristics of DC Generator

The characteristics of any motor are done to know the performance of the machine in different conditions. What happens if we increase the excitation, current, and load current. We can know these values from the performance characteristics. Generally, these are plotted considering different parameters. These characteristics help us to select a suitable motor based on the requirement.

Usually, the characteristics are of three types. They are

- OCC (open circuit characteristics)

- Internal characteristics, and

- External characteristics.

Advantages

- Design is simple

- Simple operation

- Highly reliable

- Constant voltage can be achieved

- Speed control is easy.

Applications

- These are used as boosters, in welding equipment, to charge batteries in solar systems, in an emergency at house and offices.

Thus, in this article, we had an overview of a DC generator. It is a machine that converts the mechanical energy supplied into electrical energy. The output obtained from the generator is direct current. Apart from this, we had also studied the construction, working, how EMF is generated, the basics of armature reaction, characteristics, advantages, and application of DC generator. Here is a question for the readers, what are the different effects of Armature reaction?