A wire is an electrical conductor that carries electricity where the conductor of wire is made with aluminum or copper. Similarly, a cable is a set of one or more different wires used to transmit electric current. It is necessary to know different kinds of wires & their characteristics controlled by the NEC or National Electrical Code for different installations & applications. There are many factors that need to be considered for selecting a proper composition like wire size and wire lettering. This article discusses an overview of electrical wiring, its types, differences, and its applications.

What is Electrical Wiring?

Electrical wiring is the network of cabling used for distributing electrical energy to different outlets like switches, fans, fuses, lights, sockets, etc. Once electrical wiring is correctly conducted within a building, then control & distribution of load is better. There are different types of electrical wires available in the market which are used for making connections between mains supply and loads.

Materials

Electrical wiring is made with different materials like aluminum, silver & copper. Generally, silver material is very expensive, so aluminum & copper materials are mostly used in electrical wiring. Electrical wiring materials are normally categorized into three types based on their properties; conducting materials, insulating materials, and semiconductor materials.

Conducting Materials

Conducting materials used in electrical wiring mainly include; copper and aluminum which are discussed below. Copper material is a good conductor of electricity which is used in the wiring of materials within cables. This material has less resistance & is utilized for electricity conduction at low, medium, and high voltage. This material is used in cable making & wiring.

Conducting Materials

Aluminum material is very cheap and lightweight as compared to copper material. This kind of material is frequently used in electrical wiring & cable making. The color of this material is silvery–white & it has a very soft surface

Insulating Materials

The materials that are used for insulating purpose is known as Insulating materials like paper, rubber, silicone, cotton, ceramic, mica, Teflon, glass, wood, etc. These kinds of insulating materials are very bad conductors with current. These materials have different properties like electrical, visual, mechanical, thermal, and chemical. The proper type of material selection is very significant because equipment life mainly depends on the material type. These materials are used in electronic systems, cable & transmission lines, electrical rubber mats, power systems, portable devices, protective devices, etc.

Insulating Materials

Semiconductor Materials

Semiconductor materials have conductivity in between conductors like metals & insulators or non-conductors like ceramics. The most frequently used semiconductor materials are; germanium, silicon, and gallium arsenide. Si (Silicon) material is used in most electronic circuit fabrication whereas gallium arsenide material is used within laser diodes, solar cells, and many more.

Semiconductor Materials

Electrical Wiring Colors

Electrical wires are available in different colors, so these wires indicates which color wire carries current and which wires are used for neutral or grounding purpose. Knowing the colors of electrical wiring will assist you in knowing the main purpose of every wire function. For instance, red & black color wires carry current, so these are known as hot wires. Similarly, green color or bare copper wires are mainly utilized as ground wires and gray & white color wires indicate neutral wires.

Electrical Wiring Colors

Black Color Wires

Black color wires are known as hot wires which are used for transferring electricity in all kinds of electrical circuits to your switches & outlets. These color wires are very common within normal residential wiring.

Red Color Wires

Red color wires are secondary live wires within 220 & 240 volt circuits. In certain electrical circuits, these wires are used as switch legs. But the main application of this color wire is; it is used to connect hardwired smoke detectors with the power system.

Blue and Yellow Color Wires

These color wires are live wires which are pulled throughout a conduit. Yellow color wires are used as switch legs for ceiling fans or structural lights and also used for outlets that are coupled through light switches. Blue color wires are frequently used for three-way or four-way switches. These two wires can be found very rarely in NM cable.

White & Grey Color Wires

These color wires are normally neutral and these wires serve the exact same function in most households. In electrical panels, these wires help in connecting the neural bus for carrying power reverse to it instead of transmitting from the electrical panel to a device. These two wires carry a certain amount of current, which frequently occurs whenever a circuit load is unstable.

The white color wire is a neutral wire that takes any idle electricity & transmits it back to the breaker panel whereas the green color wire is the GND wire that takes electricity back toward the breaker panel, after that external rod which is buried within the ground.

White Color Wires with Tape

If a white color wire is covered with black or red color tape, then it is used as a hot wire but not a neutral wire. Here, the tape is wrapped normally around the insulation. This is used when a two-wire cable requires a second hot wire, particularly for a 240V circuit/appliance.

Green Color Wires

Green color wires known as ground wires, so used in GND electrical circuits. These color wires become live when any fault occurs in the circuits because they provide a way for electricity to escape into the GND. These wires should never be utilized only for grounding not any other purposes. Green color wire with bare copper & yellow stripes is also GND wires

Electrical Wiring Symbols

Electrical wiring symbols are used to represent the components & electrical devices within a circuit. So, these symbols are standardized through international organizations like IEC or International Electrotechnical Commission, ANSI or the American National Standards Institute & the IEEE or Institute of Electrical and Electronics Engineers. But, there is a variation in different industries, manufacturers & regions. So, consulting related standards & specifications is necessary for understanding or making wiring diagrams.

Types of Electrical Wiring

There are four types of electrical wiring systems; cleat wiring, batten wiring, casing & caping, and conduit wiring which are discussed below.

Cleat Wiring

Cleat wiring is the most straightforward & cheapest electrical installation, used frequently for temporary electrical wiring systems. This kind of wiring utilizes a system of cleats for protecting insulated wires in position & placing them out within the electrical grid. Generally, the cleats are made from porcelain or wood into two parts that you screw into place. In this type of wiring, insulated wires with PVC or VIR are used. These wires are mounted on the ceilings & walls with the help of porcelain cleats, plastic, or wood. This wiring is not suitable for use in residential areas but suitable for temporary settings like buildings in construction.

Cleat Wiring

Cleat wiring advantages are; that its fitting is very simple, cheap & suitable for temporary fitting. It is simple for detecting faults and easy to repair. Cleat wiring disadvantages are; that its appearance is not good, this wiring is not secure and strong, there is a chance of fire or shock, not sustainable, applicable in low temperature places only, and can be affected by its surroundings. Cleat wiring is used in army campuses, Industries, and marriage functions for different kinds of wiring

Batten Wiring

This is a very old wiring method where all wires are connected through an iron clip on a wooden strip and this collection is utilized in huge quantities. This clip is a belt to a wristwatch, located on top of the primary strip & after that by laying wires on the strip, it is connected well by this clip.

In this wiring arrangement, TRS cables through single or many cores are used. These types of cables may be resistant to chemicals & steam. As compared to other wiring, this wiring has less cost and is used within an electric circuit.

Batten Wiring

The advantages of batten wiring mainly include; that it is straightforward and cheaper as compared to other wiring. This kind of wiring looks great and is very simple to repair. The disadvantages of batten wiring mainly include; that we cannot do this wiring in the open outside the house. This kind of wiring is not defended from the outside environment due to its high impact on the weather. In this wiring, heavy wiring cannot be utilized, needs more wires & cables.

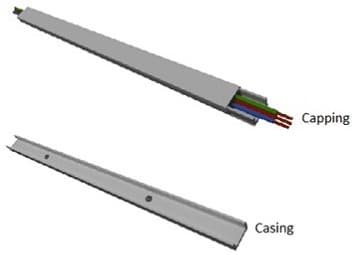

Casing & Capping

This kind of wiring is extremely popular because it is extremely simple & also very cheap. In this configuration, VIR cables are protected by wooden enclosures. In this type of wiring, wires insulated by PVC are enclosed in plastic casings & defended through a cap. This is one of the oldest & most frequently used wiring. This wiring is normally recommended for low-voltage wiring in offices, devices, and homes for wire distribution & protection.

The casing of this wiring is normally a rectangular strip by a white or grey channel & cap. This wiring comes in 1.5 inches size & 0.8 inches thickness with 39.4 inches length. The lifespan of this type of wiring is 20 years and is used in offices & homes.

Casing and Capping

The advantages of this wiring include; this wiring is cheaper, easier, very strong, and long lasting, changes to this wiring is very simple; no possibility of electric shock, and its repair is easy. The main drawback of this wiring is; that this wiring has plastic material, so there is a possibility of a fire due to short circuits and it is not suitable in industries in acidic environments.

Conduit Wiring

Conduit wiring is the most frequently used wiring. This type of wiring is done with a conduit which provides lane & safety to the electrical wiring. Generally, conduits are made with fiber, plastic & fired clay. The conduits are mostly rigid, although the flexibility can be modified based on the necessities. Conduit wiring normally uses the PVC insulated cables, cords & wires. To fix conduit wiring, cables & conduit boxes are the essential necessities.

Conduit Wiring

Conduit wiring advantages are; that it is the safest wiring and looks good because it is laid below the plaster & painting. When these wires are insulated, then they avoid the damage risk because of external factors. The conduit wiring maintenance is simple, repairing & customization is possible. This wiring is reliable and popular, utilized in different weather conditions and electric shock risk.

Conduit wiring disadvantages are; that its installation cost is high because it uses metallic pipes, the installation procedure is complex, and metallic pipes in this wiring can cause electric shock. The applications of conduit wiring mainly include; a home, garage, barn, or shed. Flexible metal conduits are used in commercial buildings. The thick & galvanized conduits are utilized in outbuildings wherever conduits can be injured. By using conduit wiring, the installation of the service feeder is done.

Comparison between Different Wiring Systems

The difference between different wiring systems is discussed below.

| Cleat Wiring | Batten Wiring | Conduit Wiring | Casing & Capping Wiring |

| This wiring has ordinary VIR (or) PVC insulated wires. | Battern wiring includes all cables, control gear & pertinent security components. | This wiring includes either PVC or VIR cables. | This wiring has PVC-insulated wires which are enclosed within plastic casings & defended by a cap. |

| The lifespan of cleat wiring is short. | The lifespan of batten wiring is long. | The lifespan of batten wiring is very long. | The lifespan of casing and capping wiring is quite long. |

| Its cost is low. | Its cost is medium. | Its cost is very high. | Its cost is medium. |

| This kind of wiring needs semi-skilled labor. | This kind of wiring needs semi-skilled labor. | This kind of wiring needs very highly skilled labor. | This kind of wiring needs highly skilled labor |

| Its installation is very simple. | Its installation is simple. | Its installation is very difficult. | Its installation is very difficult. |

| Its repair is simple. | Its repair is easy. | Its repair is very difficult. | Its repair is a little difficult. |

| There is a risk of fire. | There is no possibility of fire. | There is no possibility of fire. | There is a very high fire risk. |

| Its maintenance is very easy. | Its maintenance is very easy. | It requires maintenance. | It needs maintenance. |

What kind of wiring is used in homes?

Non-metallic cable or NM cable is commonly used in homes. These cables have a minimum of three or above conductors which have been enclosed in plastic sheathing for safety.

What is neutral in electrical?

A neutral wire in electrical is a current-carrying conductor that brings the current supply back to the power source for establishing control above the voltage.

Why are electric wires coated with PVC?

Electrical wires are coated with PVC insulators to keep us safe from electric shocks.

Why are electric wires made of copper?

Electric wires are made with copper because it is a very good conductor of electricity.

When to use conduit for electrical wiring?

Conduit is used whenever electrical wires run through walls to defend them from injury & fire risks.

Thus, this is an overview of electrical wiring, its types, advantages, disadvantages, differences, and applications. The process of connecting wires & cables to the associated devices like switches, fuse, lights, sockets, fans, and many more to the main distribution board is known as electrical wiring. Here is a question for you, What are the types of conduit?