Vacuum pumps are extensively used in refrigeration, air conditioning, etc. systems. They are used to remove air, non-condensable items such as water from a system. Removal of water in the system makes the refrigeration effective since the presence of water would corrode the internal parts of the system and cause inefficiency. The removal of water needs a vacuum pump to be operated. Similarly, it plays a major role in air conditioning systems also. Removal of air would contaminate the system. Therefore it becomes important to vacuum the air or water molecules for the effective use of the system.

What is Vacuum Pump?

Definition: It is defined as a device that removes gas molecules, or water molecules from a particular enclosed space and leaves a vacuum behind. The vacuum is defined as the absence of air. So the vacuum pump removes air for air conditioning systems, or water for refrigeration systems to create a vacuum behind. A vacuum pump is a set of systems combined together for the application.

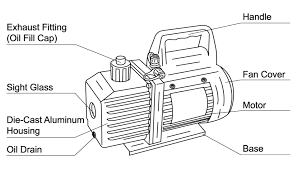

Vacuum Pump

The above figure represents the schematic of the vacuum pump including the parts of the pump. The function of each part is explained in brief below:

Exhaust Fitting- For filling oil into the pump

Handle: For transportation purpose, to carry from one place to other

Fan Cover: It covers the fan inside, which is used for cooling the motor. The fan cover also protects the fan from dust.

Motor: It is the heart of the system. It consists of a three-phase or single-phase induction motor which rotates the pump for sucking gas molecules or water particles. One sucked it creates a vacuum. The motor consists of a squirrel cage or a wound rotor induction motor. The motor again consists of a stator and a rotor. In the stator, the three-phase coils are placed which when are excited with three-phase supply, produce a magnetic field.

Base- This acts as a medium for placing the pump on the ground. It must be able to withstand the weight of the pump.

Oil Drain- This inlet is used to circulate oil inside the system. The oil is used for cooling and lubrication purposes.

Die-Cast Aluminum- It forms the outer part of the pump. It houses the compressor inside.

Slight Glass- This is used to indicate the level of oil in the system. Based on indication, oil is refilled periodically.

Vacuum Pump Working Principle

The vacuum pump consists of two major components. Motor and Compressor which are interconnected through a shaft. For large systems, two-stage compressors are installed. The left part of figure 1 which is the compressor part is elaborated in Figure 2. The details of the components are briefly described as:

Vacuum Pump Construction

Inlet- This is connected to the system where a vacuum is to be created. For example, if we want to create a vacuum in the refrigeration system, then it is connected to the inlet.

Exhaust Outlet- It is connected to push the molecules outside. For a vacuum pump, the air is induced inside from inlet and exhausted outside from the exhaust outlet.

Exhaust Valve- On the creation of low pressure, the valve opens to induce air outside.

Stator- It forms the outer part of the pump where the compressor is placed. It is made of cast iron to support the compressor system. In this part, the three-phase coils are placed which form the magnetic field for the motor to work.

Spring- It is connected to a shaft which rotates inside the stator. When the motor runs, it rotates the springs along with the blades and rotor.

Pump Oil and Oil Reservoir- Oil is used for cooling and insulation purpose.

The nonlinear air gap distribution between shaft and stator which is also called a compressor chamber eccentric in shape. The principle behind a vacuum is the difference in pressure between exhaust outlet and inlet. As we know, air flows from high pressure to a low-pressure area, and water from high height to low height, the vacuum is created by creating a difference in pressure. The difference in pressure is created due to the eccentric shape of the compressor chamber.

When the shaft moves, it rotates the rotor of the compressor. When the rotor rotates, due to the eccentric shape of the air gap, low pressure is created below the exhaust valve. When this pressure becomes enough, the exhaust valve opens and air or water molecules are forced outside. This creates a vacuum in the inlet valve. For a large system, two-stage compressors are also used. In that case, the inlet valve of the second compressor is connected to the exhaust valve of the first compressor. The two compressor chambers are connected in series.

The rotor shaft when rotates creates a region of low pressure so that the gasses or water molecules to be evacuated will rush into the low-pressure area. The rotor rotates such that, a balance in the system is maintained. The rotor of the shaft is not perfectly centered, such that a difference in the pressure can be created by varying the volume. The springs are attached to rotor such that they can be compressed to create a difference in the volume.

Vacuum Pumps Classification

Vacuum pumps can be broadly classified as shown below:

Entrapment Type

- Gas Retained in pump

- Cryo and Ion

Gas Transfer

- Kinetic

Diffusion and Turbomolecular

- Positive Displacement

They are broadly classified as entrapment type and gas transfer. In the entrapment type, the gas is retained in the pump. It is of nature cryo and ion. For gas transfer, it is of the type kinetic and positive displacement. The kinetic is of diffusion and turbomolecular in nature.

Based on the induction motor used in vacuum pumps, they are also classified as single-phase or there phase vacuum pumps. Most of the applications except a few in the industry are single-phase pumps only. For large systems like air conditioning of large buildings or huge refrigeration systems, we have three-phase vacuum pumps.

Vacuum Pump Uses/Applications

The vacuum pump has the number of applications in industry, residential, and commercial areas. In air conditioning systems, it is used to circulate air for an enclosed space. The circulation of air causes a difference in temperature and hence cools the system. Similarly, for the refrigeration system, it is used to circulate water to cool the system. Apart from that vacuum pumps are also used in vacuum cleaners, commercial applications, thermoforming, and drying applications, in conjunction with hydraulic pumps, automobile industry, etc.

FAQs

1). What is the unit of a vacuum?

The SI unit of vacuum is torrs. The SI unit of pressure is the pascal.

2). How much PSI is a vacuum?

About 14.7 PSI forms a vacuum. Also known as 29.92 of mercury (Hg) or 760 mm of mercury (torr).

3). Is vacuum negative pressure?

Yes, a vacuum is also known as negative pressure. Also known as negative gauge pressure, as it reflects differential reading between the surrounding atmospheric pressure and pressure in the system evacuated.

4). How a vacuum is created?

The vacuum is created by making a difference in the pressure. The gas or water molecules travel from high pressure or low-pressure area.

5). What is a high vacuum pump?

The pressure up to 10-3 to 10-8 is known as a high vacuum pump. Since the pressure up to this level requires a huge system, it is classified as a high vacuum pump.

Hence we have seen, the operating principle of vacuum and its applications. This particularly has huge applications in refrigeration systems and air conditioning. Here is a question for you, how vacuum pumps are different from vacuum cleaners which we use in day to day life?