The word capacitor comes from ‘capacity’ and a capacitor has the capacity to store electrical power. Capacitors are an integral part of electrical circuitry, in power circuits, their role as power factor improver and power storage device cannot be underemphasized. After batteries, the capacitor is the only device that can store electrical power. Capacitors are also used as power quality improver. However, in electronic circuitry, capacitors have many more different roles to play. In ceramic we have found a material that is of great importance in miniaturization of capacitors used in electronic circuitry and hence we have ceramic capacitors. Although various types and capacities of capacitors are used for different applications. Here, we shall restrict ourselves to the ceramic capacitor only.

What is a Ceramic Capacitor?

Definition: The ceramic capacitor has a fixed value of capacitance in micro or Pico farads which is achieved by using ceramic as a dielectric medium between the layers of conducting foils/plates. Ceramic being nonconductive, non-metallic, and helpful in retaining electric charge on the plates even at high temperatures is being used as a suitable medium.

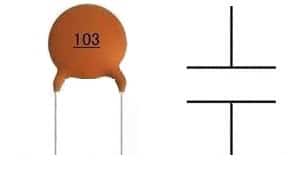

Ceramic Capacitor Polarity and Symbol

The ceramic capacitor is a non-polar capacitor, which gives it the flexibility to use with any polarity and supply (AC/DC). The symbol of a ceramic capacitor which is universally accepted is as given hereunder.

Ceramic Capacitor Symbol

Ceramic Capacitor Construction

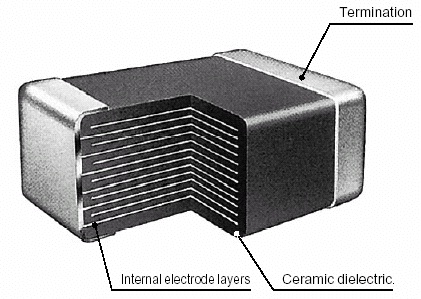

Ceramics, due to their superior insulating and dielectric qualities, they were used in capacitors. By using ceramics, we could

make capacitors into different shapes and sizes. As capacitance very much depends on the surface area of electrodes (plates). Therefore in order to increase the surface area, we go for multi-layer construction, which gives us the benefit of higher capacitance in a compact and small size. It behaves as if many capacitors were connected in parallel. Such capacitors are also known as multi-layer ceramic capacitors (MLCC).

Ceramic Capacitor Temperature

The above section of a multilayer ceramic capacitor shows how terminations are placed and how ceramic is placed between the electrode layers. Ceramic capacitors also come either in chip or dish construction and have very small values of the order of Pico or nano Farads (unit for measurement of capacitance). In a dish type construction, we have two small circular dishes which form the electrodes and ceramic is used as the filler between the two electrodes.

Ceramic Capacitance Types

As discussed above, ceramic capacitors can be classified based on the shape and construction. We shall now see how the variation in the dielectric medium can also change the type of ceramic capacitor. Different dielectrics give different properties to the capacitor. Based on this, ceramic capacitors are classified into classes 1,2, and 3.

Class Description

Class 1: These ceramic capacitors offer a high level of stability and exhibit low loss levels and they are ideal for use in resonant circuits.

Class 2: These ceramic capacitors offer high volumetric efficiency, i.e. large capacitance for a given volume for smoothing, by-pass, coupling, and decoupling applications.

Class 3: These ceramic capacitors offer higher volumetric efficiency than the class 2 ceramic capacitors, but their temperature stability is not so good. Accuracy of these capacitors is low, and are known as general purpose capacitors.

With the advancement in electronics now a day’s, surface mounted ceramic capacitors are also in use.

Characteristics of Ceramic Capacitors

The characteristics of ceramic capacitors very much depend on the dielectric medium used and the construction (monolithic or multilayer), Titanium dioxide is used with additives to get the desired characteristics in a ceramic capacitor.

The basic characteristics of these capacitors are: They can be miniaturized, can handle higher voltages, and can give accurate capacitance with low tolerance value. Multilayer ceramic capacitors are usable over a wide range of frequencies.

By altering the dielectric composition, we can make these capacitors with the least variation in capacitance over a wide range of temperature changes. Such capacitors are called temperature compensated type.

Similarly, a ceramic capacitor can be engineered to perform under large frequency variations and with high dielectric constant.

Advantages/Disadvantages of Ceramic Capacitor

The advantages include the following.

- Ceramic capacitors are non-polar and can be used for both AC and DC supplies.

- These capacitors very compact and can be miniaturized and mass-produced.

- Due to nonpolar nature, these capacitors perform well as various frequency filters.

- The cost of these capacitors is low

- These capacitors can withstand voltage variations.

- This capacitor can be engineered to perform under low frequency with a large dielectric constant which reduces the size without compromising on capacitance.

- These capacitors have a good life span.

The disadvantages include the following.

- These capacitors are available in low values only up to some micro-farads and their mechanical strength is low.

- Ceramic capacitors sometimes pick up mechanical vibration and produce noise due to the microphonic effect.

- During the manufacturing process, the ceramic layer may become uneven with variation in thickness and also may have voids resulting in the deteriorating performance of the capacitor which may cause premature failure.

Applications of Ceramic Capacitor

The applications of this capacitor include the following.

- Because of their non-polarity, low cost, and availability in a wide range these capacitors are used as general-purpose capacitors.

- These capacitors are used for minimizing RF noise due to commutation.

- The maximum application of these capacitors is found in resonant circuits at transmitting station, bypass filters, coupling or decoupling, oscillators, etc.

- Surface-mounted ceramic capacitors are used in PCB’s for high-density applications.

- For voltages up to several hundred volts multi-layer ceramic capacitors are used with PCBs.

- These capacitors are also used in power applications like induction furnaces, power supplies, filters, etc.

- Ceramic capacitors are also used in snubber circuits for the protection of semiconductor devices and in the aviation industry.

FAQs

1). What is the use of a ceramic capacitor?

A ceramic capacitor is a very important component in a circuit and finds its use in many electronic and power circuits. These are commonly used in communication, aviation, and power circuits.

2). Is a ceramic capacitor polarized?

No, a ceramic capacitor is not polarized and can be used in both AC and DC supply.

3). Why ceramic capacitor has no polarity?

The ceramic capacitors have no polarity because of their uniform construction of the dielectric medium. Only electrolytic capacitors are polar due to their construction.

4). Can a ceramic capacitor go bad?

Yes, ceramic capacitors can go bad mostly due to high voltage, which results in rupturing of the dielectric due to which the capacitor becomes Leakey. It may also go bad due to some manufacturing defect.

5). What is the working voltage of a ceramic capacitor?

The working voltage of a capacitor has to be less than its rated voltage. In the case of a ceramic capacitor, the voltage can be between a few volts to a few kilovolts. However, the capacitor can be tailored for higher and lower voltages.

Thus, ceramic capacitors having a wide range of applicability and have a great scope for further development. The capacitor performance can be tailor-made, by altering its dielectric medium and to some extent its construction. A deeper insight into it will enable us to choose the right capacitor for our application. Designing an electronic circuit without proper knowledge of capacitors is just like riding a boat without a rudder.