Temperature sensors and temperature switches are the two most significant devices utilized in different industries & applications for monitoring as well as controlling temperature. But the main difference between these two is; that a temperature switch is an electronic device used for opening or closing an electrical circuit whenever it reaches a particular temperature whereas a temperature sensor is a device used to measure its surrounding temperature & provides an o/p signal that corresponds to the temperature. Both devices are mainly used to measure temperature, but they vary in their functionality as well as application. Examples of temperature switches are; Thermostats and thermal fuses whereas RTDs and Thermocouples are examples of temperature sensors. This article discusses an overview of a temperature switch, its working, and its applications.

What is a Temperature Switch?

A switch that is used for opening and closing switch contacts is known as a temperature switch. The switching condition of this switch simply changes based on the input temperature and this function can be utilized as safety against overcooling or overheating. Generally, these switches are accountable for monitoring machinery & equipment temperature which are used for limitation of temperature.

This switch is mainly designed for detecting temperature changes & turns on or disables a switch depending on the set temperature thresholds. These are versatile devices that merge the functionality of a sensor as well as a switch to make it ideal for monitoring & controlling temperature within various applications. These switches are used commonly within electronic devices, HVAC systems & industrial processes wherever accurate temperature regulation is essential.

Symbol

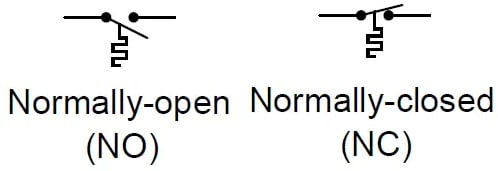

The temperature switch symbol for NO (Normally Open) and NC (Normally Closed) is shown below. A normally open (NO) contact is the one that will stay open until a certain condition is satisfied whereas normally closed (NC) contact is the one that remains closed until a particular condition is satisfied.

Temperature Switch Symbols

Temperature Switch Working Principle

These switches work based on the thermal sensing principle. Thermal switches include a temperature sensor which helps in detecting temperature changes & a switch mechanism reacts simply to these changes. Once the temperature goes above a predefined threshold, the switch is triggered & the temperature drops below another threshold, then the switch will be deactivated.

These switches use different temperature sensors like analog and digital sensors. Analog temperature sensors provide a cost-effective solution mainly for temperature detection within various systems whereas digital temperature sensors offer precise temperature sensing & are used commonly in applications that need high accuracy.

Construction

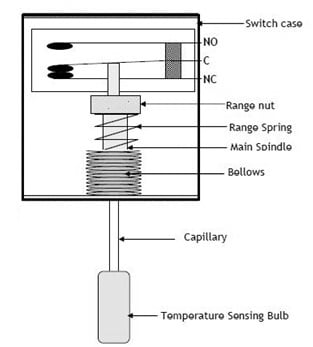

The temperature switch construction is shown below which includes different components like; the switch case, range spring, range nut, main spindle, capillary, bollows & temperature sensing bulb. In this switch diagram, the fluid in the temperature-sensing bulb will react to changes in temperature. Whenever temperature rises, then pressure in bellows will be increased. As a result, the increase within the temperature-sensing bulb will reduce the bellows and the spindle can be moved up until the spring force & the bellows pressure are stable. The movement of the spindle is moved to the switch and it causes ON and OFF action depending on the set point of the switch.

Temperature Switch Construction

Working

The temperature switch works simply based on the temperature changes occurring within an enclosed space. The main function of this switch is to activate whenever temperature changes take place. Whenever the sensing probe of this switch notices any increase in temperature, it will open the electric contacts. Likewise, if this switch notices a reduction in temperature after that electrical contacts will be simply closed. Thus the changes within temperature can be utilized for activating a switching mechanism.

Temperature Switch Circuit Diagram

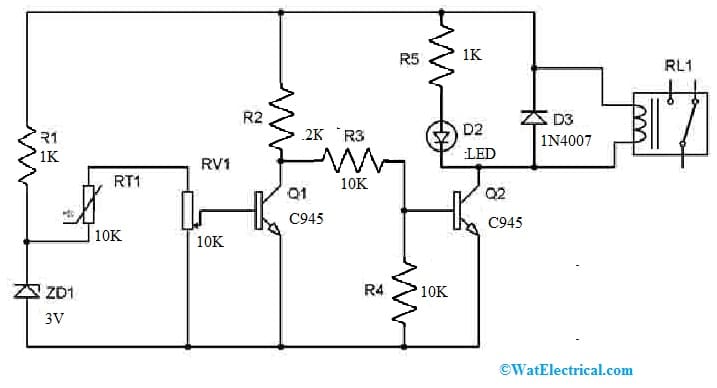

The temperature switch circuit is shown below which is used to control different systems based on the nearby temperature. This circuit with a C945 transistor maintains the temperature of a small covered region. The required components to make this circuit mainly include a C945 transistor, 10K thermistor, 3V zener diode, 1N4007 diode, 100uf 50V electrolytic capacitor, 12V relay, two -10K, 2.2K and 1K resistors, 1 – two pin and three pin terminal blocks, 1 LED and connecting wires. Connect this circuit as per the circuit shown below.

Temperature Switch Circuit Diagram

The major components used in this circuit are; a C945 transistor, 3V zener diode, 10K thermistor, and 1N4007 diode which are discussed below.

The C945 transistor is an NPN transistor that is used widely in different electronic circuits. This transistor provides low voltage output & high current gain because it is a low-power amplifier & switching transistor. This transistor handles 50V of maximum voltage which is suitable to use in different applications. This transistor is capable of amplifying weak signals, so used in audio & RF-based applications.

A 10K Thermistor is a kind of resistor used to exhibit a change within resistance depending on temperature. This thermistor has 10,000 ohms resistance at 25 degrees Celsius. Whenever the temperature varies, then thermistor resistance will be either increased or decreased based on the kind of thermistor. The main function of this thermistor in this circuit is to detect the surrounding temperature. Once the temperature goes beyond a certain threshold, then its resistance will be changed triggering the switch operation.

The 1N4007 is a rectifier diode that is capable of handling high currents & voltages. This diode is used commonly in power supply circuits for changing AC to DC. This silicon diode simply offers 1000V of a maximum reverse voltage.

The main function of this diode within the circuit is to defend the other components against reverse voltage. This diode allows the flow of current in a single direction only to avoid any harm to the circuit because of the reversed polarity.

3V Zener Diode is a special type of diode that works in the reverse-biased region & maintains a stable voltage across the terminals of the diode. This diode has a 3V breakdown voltage so whenever the voltage across the zener diode goes beyond 3V, then it will start conducting by maintaining the voltage constant across the diode. The main function of this 3V zener diode in this circuit is to provide a constant reference voltage. So this voltage can be used as a comparison through the voltage across the thermostat to decide if the temperature has gone above the preferred limit.

Working

These switches are flexible devices that can be used for controlling various systems depending on the nearby temperature. The C945 transistor provides the amplification required amplification to notice changes in temperature whereas the 10K thermistor detects the temperature. The diode in this circuit defends the circuit against reverse voltage & the 3V zener diode offers a stable reference voltage.

Whenever the temperature goes beyond the preferred threshold, then the thermistor resistance will be changed by triggering the switch operation. After that, this switch can be used for controlling different systems like heaters, fans & other appliances depending on the nearby temperature. Making this simple and effective circuit for controlling systems depending on temperature plays a vital role in industrial (or) domestic applications.

Types of Temperature Switches

These switches are classified into two types mechanical temperature switches and electronic temperature switches which are discussed below.

Mechanical Temperature Switches

These switches are classified into two types; bimetal & gas-actuated types which are discussed below.

Bimetal Temperature Switch

These switches include a bimetal disc which helps mainly in determining the temperature. These switches include two metals; zinc & steel or brass & steel where these two are utilized as platelets or strips. These metals have different thermal coefficients. Whenever this switch reaches nominal temperature because of an increasing ambient temperature, then the bimetal disc of this switch will be changed to its reverse position. This switch will return to its before state after it cools down to the reset switching temperature.

The power supply for these switches through electrical latching is interrupted before it switches back. To attain the maximum clearance from one another, the bimetal discs are in concave shape once they open. Because of the heat effect, the bimetal will deform in a convex way & the surfaces of contact can stroke each other securely. Additionally, these switches can be used as a thermal fuse or over-temperature protection.

Bimetal Type

Gas-Actuated Temperature Switch

These switches are mainly developed for safety-critical applications. These are high-quality switches because they are manufactured with ISO 9001 for consistent plant monitoring. These types of switches are traced through quality assurance software at each step and they are 100 % tested. These switches are set with micro switches for flexible operation which enables an electrical load switching up to 250 V AC, 20 A directly.

These switches are used for temperature monitoring & controlling processes. These are used in safety-critical applications within general process instrumentation, particularly in the petrochemical as well as chemical industries, gas & oil industries, power generation including; water or wastewater industries, mining, and nuclear power plants.

Gas-Actuated

Electronic Temperature Switches

These switches are mainly used for recording temperatures nearly in all technical processes. These switches help in recoding temperatures in off-shore, shipbuilding, chemical sector, petrochemical, mechanical engineering, plant engineering, tunneling technology, cooling systems, hydraulic power packs, power plants, food, and beverage industry, etc.

These types of switches include a power supply source, electronic circuit & measuring element. This type of switch is mainly used for measuring temperature by simply changing it into a switching signal throughout the change within the measuring element temperature. So this switching signal will change in proportion to the temperature & can be measured accordingly. These switches are mainly applicable wherever high accuracy is required.

Electronic Type

Advantages and Disadvantages

The advantages of temperature switches include the following.

- The advantages of using a mechanical type switch include low cost, ruggedness, not requiring a power source, and simplicity of operation.

- These switches assist in reducing production costs by self-testing capabilities.

- These switches allow systems to be autonomously protected with integrated and selectable hysteresis for improved noise immunity & decrease system size equal to 50% against discrete implementations.

The disadvantages of temperature switches include the following.

- These are expensive.

- Not every temperature switch works through every heating & cooling system.

Applications

The uses or applications of temperature switches include the following.

- These switches are mainly used in different technical and industrial processes. This switch will open or close the corresponding switch contact once it reaches a preset temperature.

- These switches are used in compressors, mobile hydraulics, compressors, pumps, machine building, heating and cooling circuits.

- These switches are normally used in industries to limit temperature by monitoring the equipment machinery temperature. For instance, switch ON a fan for cooling the equipment and switch off machinery once it overheats.

- These switches are specially designed for use in heating systems, boilers, circulation pumps, air heaters & burners. They are typically used across a wide range of general-purpose applications, although these are particularly significant in industries like pharmaceuticals, automotive engineering & foodstuffs.

- Mechanical type switches are mainly used in a wide range of applications like mobile working machines in agriculture, industrial machines, construction & material handling type industries.

What is a Temperature Switch used for?

This switch is used for opening and closing switch contacts where the switching condition of this switch will be changed based on the input temperature. So this function is used mainly as protection from overcooling/overheating.

What is a Temperature Activated Switch?

A temperature-activated switch is an electromechanical device used to open & close contacts for controlling the current flow in response to changes in temperature.

What is a High Temperature Limit Switch?

The high-temperature limit switch or furnace plenum thermostat is a protection device that is designed to cut the supply of gas when the temperature of the burner exceeds the secure operating range. Once the temperature falls back within the secure range, it allows the gas valve to open again.

Thus, this is an overview of a temperature switch, circuit, working, types, advantages, disadvantages, and its applications. This switch is also known as a thermal switch which is used for opening as well as closing the contacts of the switch. The switching condition of this switch will be changed based on the i/p temperature. So this function can be used as protection from overcooling or overheating. Here is a question for you, what is SPDT switch?