Gas turbines were developed with the advancement in the two domains of technology like internal combustion engine and steam turbine, The operations that took place in both these fields, lead to the development of current day gas turbines and this happened in the year of 1940s. During the period, 1500 – 1870s John Barber, Vinci and Branca, and other people define or develop other models that utilize steam or hot gas to develop motion. At the same time, Samuel Morel, Barnett, Samuel Brown, and Said created the design of the internal combustion engine. The fundamental understanding and hypothesis of how the gases are used and their performance in the enclosed spaces are known. So, this article gives a complete understanding of one of the types of gas turbine which is Open Cycle Gas Turbine, its working principle, advantages, and applications.

What is an Open Cycle Gas Turbine?

An open cycle gas turbine is defined as the combustion turbine plant which is fired up by the liquid type of fuel in order to trigger a generator rotor that generates electricity. There will be the exhaustion of residual heat to the atmosphere nearly at 5500C. The location of generators and turbines are in the enclosures which are manufactured for reduction of noise and occupy a space of nearly 75m * 75m per unit. The exhausted stack height is nearly at a height of 30m where the intake structure height is at 20m.

Working of Open Cycle Gas Turbine

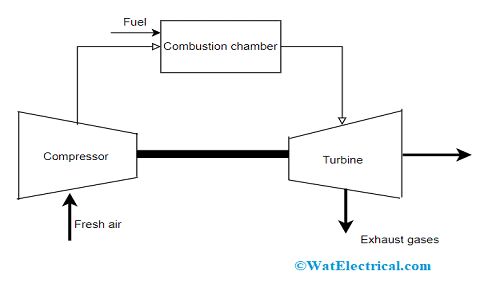

Before moving ahead to know the working principle of open cycle gas turbine, let us know the design system of the device which is that residual heat gets exhausted to a level of 5500C. Here, the generators and turbines are placed in the enclosures and those are structured for noise reduction and they need a space of nearly 75m* 25m for each unit. The height of the stack is nearly 30m whereas the intake structure height is almost 20m. The open cycle gas turbine diagram is shown below:

Open Cycle Gas Turbine Schematic Diagram

The open cycle gas turbine has three parts compressor, power turbine, and combustor where the compressor performs sucking of air from the atmosphere and then compresses it by passing through many compressor phases. Fuel is injected into the combustion compartment and it gets mixed up with compressed air. This mixture then undergoes the operation of ignition so that it generates velocity gas. This velocity gas is then allowed to pass through turbine blades which turn the shaft that is connected to the generator’s rotor section. This rotor revolves internally to the stator and generates electricity. The generated electricity is then distributed to flow across the voltage network and to other locations where it is required.

This is the open cycle gas turbine working principle.

Features

The characteristics of open cycle gas turbine are stated as follows:

- This turbine is even applicable for combined cycles

- The open cycle gas turbine efficiency is almost high which is of almost 44%

- It has enhanced reliability and extended life period

- Used for the generation of electric power and even used in aircraft propulsions

- When compared with steam kind of propulsion systems start-up time of 4 hours, the OPCGT’s have quick start-up time which is nearly 2 mins

- The proportion of back work is more which is approximately 50% whereas for steam power plants it is less

Performance Characteristics

- Possibly the main benefit of general OCGT devices are they can be initiated in lesser time and provide response quickly to sudden modifications in the electric load.

- When there is the addition of a steam bottoming cycle to the device, the devices can have a good response to load modifications whereas the startup time is somewhat more.

Advantages

The main advantages of open cycle gas turbine are explained as below:

- The open cycle gas turbine device is designed with only three components which are combustion, chamber section, and compressor. This makes the device so simple and easy to use. It is also not expensive and easy to manage to have more amount of heat release. The device can also be constructed to burn entire hydrocarbon fuels which might be heavy diesel oils as well.

- OCGT also has minimal weight and it needs minimal space per unit power output

- As the weight and size are less, the capital investment will also be minimal when compared with other types of gas turbines. This advantage allows even a low range of businesses to utilize OCGT devices

- Turbine regulation is very simple

- OCGT device can be used with any kind of gas. For example, when a combination of He+Co2 with He is used, it generates increased efficiency which can be utilized in nuclear plants

- With the combustion products, that are used in the device, there will be no damage to the turbine blades

- Minimal thermal stresses can be present at various levels of loads because of balanced temperature levels

- The operation of OCGT is not based on the atmospheric pressure and because of this any kind of pressure can be utilized so that corresponding plant output can be enhanced. Upon the application of pressure to the turbine, components size can be reduced

These are the foremost advantages of the OCGT device.

Disadvantages of OCGT

The disadvantages of open cycle gas turbine are as follows:

- When there happens a change in the component efficiency level, the device shows quick change as because it is sensitive to efficiency levels. A decrease in the efficiency levels of the turbine and compressor will automatically reduce the cycle’s efficiency.

- The device is even sensitive towards atmospheric temperature levels and an increase in atmospheric temperature decreases the thermal efficiency of the device

- When there is an application of a high level of forces at the compressor section then there will be the requirement of strong heat

- The device provides increased efficiency only when combustion room efficiency is more

- The efficiency levels are less and this is mainly dependent on the heat exchanger

Applications of Open Cycle Gas Turbine

The main applications of OCGT are:

- Open cycle gas turbines are mainly implemented in the aviation domain where they supply motive power mainly for jet propulsion

- Used for generation of electric power

- Utilized for propulsion of locomotive, marine industries and in an automotive domain also

- Implemented in the functionality of mechanical driving

Know more about Nuclear Power Plant MCQs.

Overall this is a detailed explanation of open cycle gas turbine, working principle, advantages, drawbacks, and applications. This is the prominent type of gas turbine employed to turn around the turbine by making gas as the functional fluid. In general, this is also utilized to describe the whole internal-combustion engine which consists of three sections which are a compressor, a turbine, and a combustion chamber. The other topic to be discussed and to known about this topic is what are the types of open cycle gas turbines and how they perform?