We all know that the DC generator and DC motor are the machines where the functionality of these machines is to convert mechanical energy to electrical energy and vice versa. But in this conversion process, all the provided input power is not converted into output power because there will be some power loss. This reduces the efficiency and performance of the machine. So, to construct and design DC machines with enhanced efficiency, one has to clearly observe what kind of losses lessen the machine’s efficiency and corrective measure should be taken to eliminate the losses. So, this article let you know about are various kinds of losses in the DC machine and how they happen?

Various Losses in DC Machine

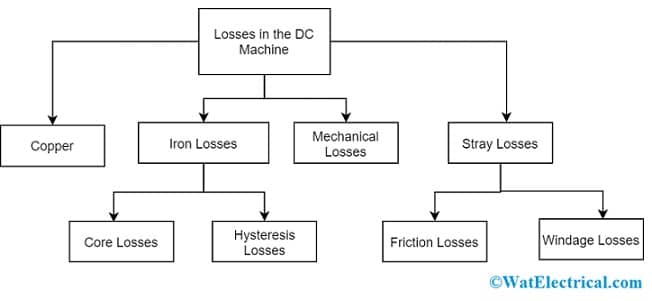

Basically, losses in the DC machine are categorized into five types. They are:

- Electrical or Copper losses

- Core/ Iron losses

- Mechanical losses

- Brush losses

- Stray Load losses

These losses are clearly explained in the below sessions.

Losses in DC Machine

Electrical or Copper Losses in DC Machine

These losses are also termed as winding losses because these happen due to the resistance of machine windings. Ohmic losses happen because of the current flow in the machine windings. Apart from the field windings, the other kind of windings are armature windings, interpoles, and even compensating windings.

Losses produced because of armature windings are Ia2Ra

Here ‘Ia’ represents current flow in the armature and

‘Ra’ represents resistance value in the armature.

Armature losses are nearly 30% of the entire losses.

Even there are other types of copper losses like the shunt field and series field. Shunt field loss has a constant value for both compound and shunt-wound machines. Whereas the other electrical losses have a direct proportion to double of armature current that changes with load.

Electrical losses in the interpole windings are represented as Ia2Ri where Ri corresponds to interpole windings resistance and electrical losses in the compensating windings are represented as Ia2Rc where Rc corresponds to compensating windings resistance.

Magnetic Losses in DC Machine

The losses are also called as magnetic losses or core losses or iron losses. These happen because of the armature rotation in the magnetic field of the poles. These magnetic losses are categorized as

- Hysteresis losses

- Eddy current losses

Hysteresis Losses

These losses happen in the armature section of the machine because any component of the armature will be imperiled to the magnetic field reversals as they authorize to consecutive poles. The frequency value of the magnetic field reversal is shown as

f = P.N/120

Here ‘P’ corresponds to the number of poles

‘N’ is the speed calculated in rpm

The magnetic loss is based on the iron grading, volume, the frequency magnetic field reversal, and the flux density. Through the Steinmetz formula, the magnetic losses can be derived and the formula is

Wh=ηBmax1.6fV, where η corresponds to Steinmetz hysteresis constant and V, corresponds to a volume of the core measured in m3

Eddy Current Losses

Apart from the voltages made in the armature conductors, there also exist voltages in the armature core. So, the voltages developed in the armature core create currents and these are called eddy currents, and the power loss that happens because of their moment is called eddy current loss. These losses appear as heat that increases the D.C machine temperature and decreases the performance. When a constant solid iron core is used in the machine, then the resistance of the eddy current path becomes less as because of the increased cross-sectional area of the armature core. Therefore, the magnitude of the loss becomes increased and this increases the eddy current loss.

As the insulating coating has increased resistance, there will be a minimal current flow between the laminations. Correspondingly, each lamination is so narrow, and the resistance to the current flow across the thickness of the lamination is more. So, core lamination enhances the core resistance that reduces the eddy current and the loss of eddy current. Eddy current loss is represented by

Pe=KeB2maxf2t2V

Where ke is the constant value, Bmax corresponds to flux density measured in wb/m2, ‘T’ corresponds to lamination core width measured in m and ‘V’ is the core volume measured in m3.

Mechanical Losses

The losses that happen due to the mechanical consequences in the d.c machines are called mechanical losses. These are categorized as windage and bearing friction losses. Mechanical losses take place in the running components of the d.c machines and the air that is present in between stator and rotor leads to windage loss. These losses are minimal (nearly 10 -20%)and can be easily reduced.

Brush Losses

The losses that happen between the carbon brushes and the commutator are called as brush losses. At the power contacting location, these losses happen. The loss is based on the brush contact voltage reduction and on the current that flows through the armature. The brush losses are given by the equation

PB = VBIa

The voltage reduction which arises across an extended range of armature currents and over an array of brushes is nearly constant. In general, the voltage drop in most of the cases is considered as 2 volts. So, the voltage drop is considered as 2Ia.

Stray Losses

These losses are termed as assorted kinds of losses. The below scenarios are taken into consideration in stray load losses. The falsehood of flux due to the armature outcome and the short circuit currents in the coil, those go through commutation.

Basically, determining of these losses is somewhat complicated. So, it is required to allocate the acceptable value of stray losses. In many of the d.c machines, stray losses are considered as a convention to be 1% of the whole load resultant power.

Both the mechanical and the iron losses are collectively termed as stray losses.

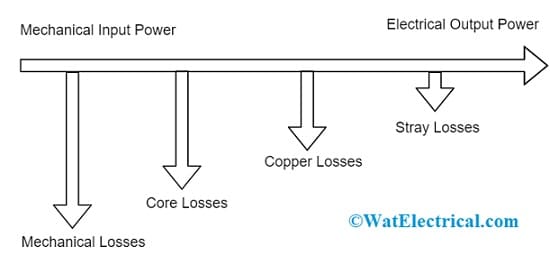

To know clearly about these losses either in a dc motor or dc generator, the best approach is to follow the power flow diagram. Here, the diagram clearly represents what amount of power is wasted in each type of loss and how much amount of power has really transformed into output. The below diagram shows the power loss in the dc machines.

Power Flow

So, this all about the concept of why losses happen in the dc machines and what kind of losses take place. When a particular kind of loss is exactly known, then it will be easy to reduce the loss and so the efficiency can be increased quickly without damaging the machine. The other concept that we need to know is how to minimize losses in the DC machine?