We all know that the progression of technology enhances day-by-day through the invention of various trends and creativities. In the same way, the approaches to cooking food and making use of fire also get enhanced. We are completely aware of how to cook, molding of metals and procedures followed in various industries and many others. But the greatest revolution that came into existence was to work on the same thing without the utilization of fire. The innovations and enhancing technologies showed up various approaches to make use of without fire for the heating procedure. One of the greatest innovations was “Dielectric Heating”. So, you might be in the thought that how this dielectric process works and many others. Let’s move into the discussion of this.

What is Dielectric Heating?

Definition: Dielectric heating is also termed as radio frequency, capacitive or electric heating. It can be stated as the process where the temperature of the electrical non-conducting substance might be increased by allowing the substance to increase the frequency of the electromagnetic field. This allows to develop dielectric losses in the substance, and this emerges in the aspect of dielectric heating. Frequencies that are in the range of 10-100 MHz are required to measure the scope of dielectric heating. Although, extended frequency ranges work better, in a few of the materials mainly liquids minimal range of frequencies has substantial heating effects, might be because of typical methodologies.

For instance, in some kinds of conductive liquids like saltwater, the effect of ion-drag develops heating due to the slow-motion of charged ions in the liquid under the effect of electric charge, also the liquid particles in the procedure and the transfer of kinetic energy to those particles which is finally delivered as molecular vibrations and so-termed as thermal energy.

dielectric-heating

Furthermore, the process of dielectric heating is also taken into consideration as volumetric which allows for effective temperature increase that means the rapid increase of heating rates by essentially removing the temperature gradient. Also, there exist corresponding variations between microwaves and radiofrequency waves. The enhanced effectiveness of the energy transmission for microwave heating purposes, the penetration halts where the complete MW energy is transformed as heat in the tissue layer. This might develop uneven heating internal to the muscle tissue. While on the other side, RF maintained at mid-frequency ranges holds extensive penetration than that of MW.

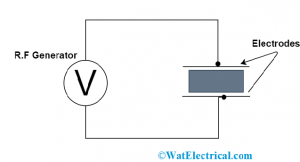

Dielectric Heating Circuit Diagram

The below circuit diagram clearly explains the dielectric heating working. The system is included with two metal plates also called electrodes where here the application of the electric field is done. The substance that has to be heated is positioned between these two electrodes.

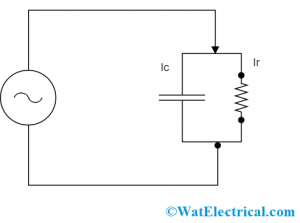

dielectric-heating-equivalent-circuit

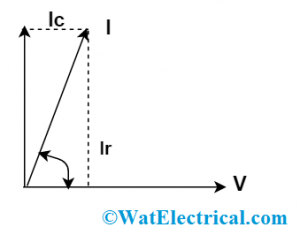

The phasor diagram corresponding to the above circuit is

phasor-diagram

There exist two approaches where the substance can be heated through the heating methodology.

- One is heating the substance through low-frequency waves like a near-field method.

- The other is heating the substance through high-frequency waves through the approach of electromagnetic waves.

Also, the approaches not only in the heating methodology but also in the kinds of materials that are used for heating purposes.

As minimal frequency systems have an extended range of wavelengths, they can easily penetrate through non-conductive substances than that of electromagnetic waves. The distance that is in between the absorber and the radiator needs to minimal of 1/2∏ wavelength, for the substances that are utilizing minimal frequency ranges. Thus, the approach of heating the material through minimal frequency ranges is like near-contact method.

And increased frequency systems have a minimal range of wavelengths. Here, the distance between the electrodes is more than the applied wavelength. Conventional far-field electromagnetic waves are developed between the electrodes.

The dielectric equation can be derived as follows:

The amount of current flow through the capacitor is

IC = Voltage/XC = V/(1/2∏fC) = 2∏fC (Voltage) Amperes

Where C is calculated in farads and Voltage in volts. The current which is drawn from the supply is

I = IC = 2∏fC (Voltage) Amperes

And the amount of power produced is

P = (Voltage) (Current) cosФ

Voltage = 2∏fC (Voltage) × cosФ watts

= 2∏fC (Voltage)2 watts

The condenser capacity is measured as:

C = ErE0 A/t farads

Where ‘Er’ corresponds to the dielectric permittivity

‘E0′ corresponds to the vacuum’s absolute permittivity and the value is 8.854 × 10-12 F/m.

‘t’ is the dielectric material thickness and

‘A’ is the entire surface area of the electrodes measured in m2

Principle of Dielectric Heating

The substance which is subjected to heating needs to be positioned in between the electrodes where an extensive range of frequencies are applied. To makes sure of appropriate losses and to provide sufficient heating, 10 to 20 MHz range of frequencies is applied while the voltage varies in the range of 10 to 20 kV. The required frequency range supply voltage is received from a device called as valve oscillator. The amount of current that is drawn by the capacitor at the time when a.c voltage is applied between the electrodes will not direct to the supply voltage by exact 900, where it implies that there exists a specific current element that is in exact phase with that of a.c voltage. As because of this element, heat is generated in the dielectric material which is in between the electrodes.

Also, the electric energy which is dispersed as heat energy in the dielectric substance is termed as a dielectric loss. This loss is in linear proportion to the multiplication of frequency and squared voltage (V2f). Due to this, an extended range of high-frequency voltages is used in dielectric heating.

So, in general, an a.c voltage of nearly 20kV having a frequency range of 10 to 30 MHz is utilized. So, as per the analysis dielectric heating delivers results of nearly 50%.

Advantages and Disadvantages

Let’s discuss the advantages and disadvantages of dielectric heating.

Advantages

- Because heat is generated all across the entire material, the output is uniform heating. Through traditional procedures, the output will not be uniform heating, and this is one of the foremost benefits of dielectric heating.

- The entire procedure requires minimal time to complete when compared with that of other methods.

- Moreover, dielectric heating is appropriate for non-conducting substances such as plastic, synthetic elements, wood, and many others.

Disadvantages

- Heating can be done only for the substances that have a high-level of dielectric losses.

- The equipment necessary for the entire process is costly and this method is only implemented when other approaches are unfeasible.

- The whole efficiency of the dielectric heating is too minimal, and it is almost 50%

- The utilization of high-frequency ranges might produce radio interferences.

Applications

Few of the applications of dielectric heating are as follows:

Preheating of Plastic Upgrades

The uncooked substances which are in the form of either medicines tablets or biscuits, generally termed as plastic preforms, is necessary to be heated linearly in advance whey they are moved into moulds and the entire mass is converted into liquid, or else when the raw substance is kept directly into the moulds, which is generally steam heated, then the preforms outer surface will become warm and initiates curing whereas the material core has not come up to fluid temperature which results in inadequate hardening of the plastic substance and not correctly filling up the corner locations in the moulds.

And the complications happen because of the reality that plastic raw substances once treated will not be transformed as soft. Any kind of technique of heating based on the conduction of temperature from the surface layer to the core will wretchedly flunk due to the fact that plastic is one of the bad conductors of heat. Thus because dielectric heating is the only approach that can be implemented preheating of plastic preforms to appropriate temperature equally.

Wood Gluing

The foremost approach of gluing wooden boards is dielectric heating. Here, in the wood gluing technique the wet contents of the wooden boards stay as unmodified. It is because of the reason that heat can be implemented at any of the preferred surfaces. The main complication in making use of the animal glues is of extended curing time and also every part has to be kept together and maintained under exact mechanical pressure then after glue application for a period of one day. Mechanical pressure might be applied for wood gluing through dielectric heating so as to provide extensive protection and good adhesion properties.

Baking of Foundry Cores

In foundries, the resin kind of thermosetting attachments is implemented as they can be easily set when reached near to polymerizing temperatures. Through dielectric heating, water can be easily removed from the core mixture and also it increases the core temperature up to polymerization point. So, dielectric heating is appropriate for baking foundry cores assimilated with the thermosetting resin kid of core binders.

Sterilization

This method is even completely appropriate for sterilization of sterile instruments, gauges, bandages, and absorbent cotton.

Textile

Here, the approach is used for drying purposes.

Diathermy

Also implemented in the processes of heating body bones and tissues necessary for healing a few kinds of diseases and ailments.

Sewing Electronically

Stitching of some materials such as umbrellas and raincoats by thread might loosen their stitches after some days and they might not be water-resistant too. In those cases, adhesive curing functions as the best. In electronic sewing, the films that are to be sewn are placed in between the cold rollers and here there will be the application of frequency voltage. So, the heat that is generated in the material tightens the surface and the cold rollers provide strong adhesion to the outer surfaces.

The other applications of dielectric heating are:

- Implemented in milk and beer pasteurization either in packets or bottles.

- Fruits, eggs and vegetable dehydration

- Applied in the process of cooking foods without cutting off the outer surfaces

- Germicidal heating-In dielectric heating procedure the foods will not lose their flavor.

- Used in the process of defrosting vegetables and meat

FAQ’s

What is the principle of dielectric heating?

Dielectric heating works on the principle of dielectric loss. A varying electric field generates energy which is to be dispersed and the molecules move in line with that of varying electric motion.

1). What is meant by dielectric loss?

The loss that is used for heating a dielectric material in the altering electric field.

2). Do radio waves produce heat?

Radio waves hold the ability to easily move into the surface and let their energy to be deposited in the materials and biological networks.

3). Is electric heat efficient?

Electric heat is totally efficient where the received electrical energy is completely transformed as heat.

4). What is power frequency heating?

The heating methodologies that are implemented in the normal frequency ranges (50 Hz) are termed as power frequency heating.

Thus, this is all about an overview of dielectric heating. The extensive advantages and applications allow this procedure to be implemented in many of the applications. Many of the domains these days are making their move towards dielectric heating. So, we would like to provide as What is the main and clear application of dielectric heating and why?