The fundamental induction heating principle was introduced and applied in manufacturing industries in 1920. During the Second World War, the development of technology has been increased to reach urgent requirements of a period of war for a quick, consistent procedure to solidify the parts of the metal engines. At present, technology is focusing on lean industrialized methods & giving importance to improved quality control of induction technology. This article discusses an overview of induction heating.

What is Induction Heating?

An induction heating can be defined as, a method that is used for connecting, solidifying otherwise make softer metals/conductive materials. In current manufacturing methods, induction heating provides a smart combination of pace, reliability & control. In common metal heating methods, open flame or a torch is openly applied to the part of the metal. However, it is induced in the element by moving electrical currents. This kind of heating depends on the exclusive characteristics of RF (radio frequency) energy.

induction-heating

How Induction Heating Works?

The induction heating method is used to heat an object which is conducting electrically (metal) through electromagnetic induction, wherever eddy currents are produced in the metal as well as resistance directs to Joule heating of the object.

For induction heating, there are two basic things are needed like an altering magnetic field and a material that is electrically conductive is located into the magnetic field.

This heater includes an induction coil by which a high-frequency AC is supplied. Heat is also generated through magnetic hysteresis losses within materials that have important relative permeability. The AC frequency mainly depends on the size of the object, type of material, coupling and the depth of penetration.

This is a rapid, clean, non-polluting heating method that can be used to change the material’s conducting properties. The coil does not get hot itself & the effect of heating is below controlled. The technology used to make heating much simpler is solid-state transistor technology, cost-effective heating used for different applications like soldering, induction heat treating, brazing, melting, forging, etc

Induction Heating Circuit

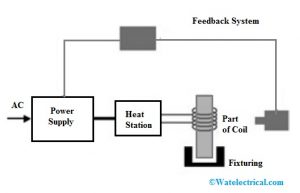

The induction heating method mainly includes RF power supply which supplies an AC to the entire circuit, and the set up of this is shown below. A copper coil can be used like an inductor as well as the current is given to it. This coil includes a material that is to be heated.

induction-heating-circuit

By changing the supplied current’s strength, we can regulate the heating temperature. When the eddy current generated within the material supplies reverse to the material’s electrical resistivity, exact & localized heating can be viewed within this process.

Heat can be generated beside the eddy current because of hysteresis within magnetic elements. The electrical resistance provided through a magnetic material in the direction of the altering magnetic field in the inductor can cause inner friction to create heat.

When this heating method is a non-contact process, then the material to be heated supplies away from the current supply or in any gaseous environments or flooded in a fluid in a vacuum. This kind of heating method doesn’t need any ignition gases.

Formula

Inductive current’s frequency determines the deepness of penetration using eddy current into the material. The effective depth of the layers which carry current can be calculated by using the following induction heating formula.

D=5000 √ρ/µf

In the above equation,

‘D’ is deepness in cm

‘µ’ is the relative magnetic permeability of the material

‘ρ’ the material’s resistivity in ohm-cm

‘f’ is the AC field frequency in Hz.

Coil Design

Induction heating coil design is very essential for the effectiveness of the coil. In this, the coil is used as an inductor where the power is applied from different forms. The flow of current which is induced in the material can be proportional to the turns of the coil.

Generally, these coils are copper conductors and based on the applications different forms of coils are used. The most frequently used coil is multi-turn helical, and the heating pattern width for this coil can be identified by the turns of the coil. The coil with a single turn is used where narrowband heating of material is needed.

The helical coil-like multi-position is mainly used for heating the number of metals. Pancake type coil is used whenever it is necessary to heat just one part of the material and finally the internal coil can be used to heat inside bores.

Important Factors

Induction heating system efficiency for an exact application mainly depends on numerous factors like the characteristics of the element, plastic or metal, thin or thick, design of inductor, resistivity, capability power supply.

Advantages

The advantages of induction heating include the following.

- It is mainly useful wherever extremely recurring operations are executed.

- It can be used to heat a small part of a workpiece, where it is needless to heat the entire part.

- it is fast and clean.

Induction Heating Applications

The applications of induction heating include the following.

- This kind of heating is used to heat surface, soldering, and melting the metals.

- By using this liquid conductor heating as well as gaseous conductors heating is possible.

- This process is used in brazing carbide to the shaft

- This heating process is used in pharmaceuticals and sealing resistant cap on bottles.

- In semiconductor industries, this kind of heating is used for silicon heating

- This principle is used in induction stoves

- This principle is used in modeling the machine of plastic injection for enhancing its energy efficiency

- It is used for welding of plastic or metals while they are doped by ferromagnetic ceramics.

- This method is used for heating metals in inductive furnaces to its dissolving point.

Thus, this is all about induction heating. In manufacturing industries, this process offers speed, control, and consistency. This method is efficient, quick & non-polluting. During inductive heating, the loss of heat can be solved with the help of Lenz’s law. This law shows a way effectively with the heat loss which occurs in the method of inductive heating. Here is a question for you, what is the working principle of induction heating?