Initially in the period 1931, the eddy current dynamometers were invented by Martin and Anthony Winther. From the year 2002, these dynamometers are manufactured with a license under Dynamatic and Eaton production line. But these instruments were not so popular because DC generators and motors were more in popularity and implementation. Being so suitable for modern-day frameworks, these devices are implemented in sophisticated applications too. Basically, a dynamometer is the one used to calculate the torque and the power which is released from the power train of the automobile. Depending on the type of absorption units or the absorbers the devices implement dynamometers are classified. So, now we are going to have a detailed look into the concept of eddy current dynamometer, its working principle, how it is constructed, advantages, and applications.

What is Eddy Current Dynamometer?

This comes under the classification of engine dynamometers and these are accurate, quick response, minimal maintenance, and repeatable substitution for the water brake technology. The instrument is mainly implemented for the purpose to calculate different characteristics of the active mechanical test apparatus. It is also used to know the performance analysis for gas and water turbines, internal combustion engines, for both small and medium-sized power motors and for many others.

Features

The main features of eddy current dynamometers are as follows:

- Enhanced rotational speed

- Minimal inertia moment and residual torque

- The device operates in both clockwise and anti-clockwise directions

- It has constant braking torque and has no shock characteristics

- Braking torque can be measured internally having no use of external devices

- Inbuilt optical speed sensor

- The device is available in 13 models having the highest torque value of 399 N.m to that of 560 N.m

- Operating braking power ranges between 500 – 140kW

- Delivers similar performance when operated in any of the direction

- It is available in single, double, and triple rotors

- Strong modular management and mechanization system

- Best cost to performance ratio

- Better stability and accuracy

Eddy Current Dynamometer Working Principle

The basic principle of the eddy current dynamometer is dependent on the Eddy current which means on the right-hand principle of Fleming’s law. The main components in this device are brake, force evaluation and speed calculation instrument, and others. Where the brake controls overloading of the prime mover and it also has the functionality to alter the absorbed power delivered from the prime mover into heat and this heat is cooled up internal cooling arrangements.

The torque calculation of eddy current dynamometer corresponds is based on the similar amount of torque that is applied and the output torque in the reverse direction. So, torque can be calculated using the revolving torque of the dynamometer which is the brake housing counter torque to signify.

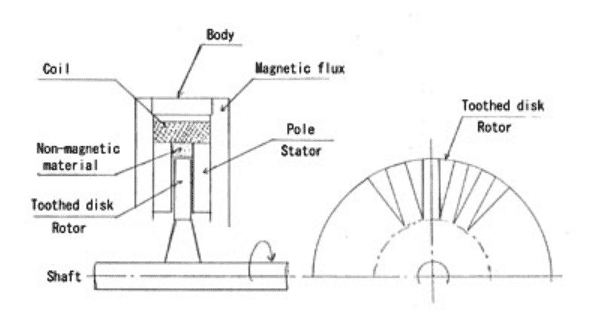

The below eddy current dynamometer construction clearly explains the operation of this instrument.

Eddy Current Dynamometer Construction

As it is already stated that the device is included with stator where electromagnets are located upon this and the rotor disc which is made up of either steel or copper and it is connected to the engine’s output shaft. The eddy currents that are developed in the stator create opposition for the rotor movement by loading up the engine. As these currents develop heat there has to be a cooling apparatus in the device. The torque is calculated in the same way as that of the absorption dynamometer that is using the assistance of the moment arm. The load can be regulated by controlling the electromagnet’s current.

This is the eddy current dynamometer working.

Eddy current dynamometer consists of the brake, measuring force and speed measuring device, etc. The brake regulates the load of the prime mover, and at the same time converts the absorbed prime mover power into heat, which is taken away by the water.

The torque measurement of the eddy current dynamometer is according to the principle of the same amount of applied torque and reaction torque in the opposite direction. So, the torque can be measured by the dynamometer rotating torque (i.e. brake housing counter-torque) to indicate.

The hard construction and efficient power absorption make sure of having increased operational life and this eddy current dynamometer have the following:

- Stator protection component

- Passage for hot air

- Cooling management

- Sensors

- Electronic manageable unit

- Load cells and excitation coils

- A calibrating lever

- Baseplate

- Trunnion assistance

Available Types and Resultant Outputs

To suit with everyone kind of application and requirement, eddy current dynamometers are available in multiple capacities and the below comparison table explains in clear

| Power capability in kW | Resultant torque in Nm | Speed in rpm |

| 40 | 160 | 18000 |

| 100 | 320 | 16000 |

| 10 | 45 | 25000 |

| 500 | 2000 | 12000 |

| 16 | 70 | 24000 |

| 25 | 100 | 20000 |

Typical Specifications

Few of the specifications of eddy current dynamometer are as below:

- The device has to be maintained with clean water having no wastage and dirt

- The pressure range for the cooling water ranges between 0.2 – 0.4Mpa

- The device has a water outlet and the temperature of this has to be <500C

- It can be operated either in the left or right-handed direction because it functions both CW/ACW directions

- As there are various kinds of dynamo classifications, it has precise torque measurement like ±4% for the range of 6kW to 100kW whereas ±0.2% for 160kW and ahead

- It has speed preciseness of ±1 rpm

Advantages

Few of the eddy current dynamometer advantages are as below:

- Streamlined construction and assemblage

- Extensive power handling capacity

- It consists of a disc rotor and so it has minimal inertia

- Increased response to modify in the input signals

- Increased operational life and even long repairing intervals

- It need only simple maintenance as because of minimal components

- Reduced downtime as its mechanical construction is so less

Eddy Current Dynamometer Applications

The applications of eddy current dynamo are:

- Releases certification work

- Implemented in the applications that require transitory test cycles

- Implemented in the applications that require drive cycles

- Automobile simulation work

- Employed in the applications that need great durability and performance

Please refer to this link to know more about Regenerative Braking MCQs.

So, this is all about the concept of an eddy current dynamometer. Here, we have gone through a detailed discussion of how eddy current dynamo operates, on which principle it functions, technical specifications and ratings, advantages, and applications. Also, there are many other concepts to be learned in this topic and one of those is how eddy current dynamometers are calibrated as per the required torque and speed ratings?