Linear Variable Differential Transformer (LVDT) and rotary variable differential transformer (RVDT) is an electrical transformer type sensor used to measure the linear displacement and angular displacement respectively. The circuit diagram and working principle is similar to each other but differentiated in terms of core and shaft movements inside the module. These sensors are also called as electromechanical transducer due to the fact that it yields variable alternating current (AC) output voltage proportional to the changes in induced electromotive force (EMF) in primary and secondary windings. In this article, the LVDT & RVDT introduction is presented. The differences between LVDT & RVDT are explained along with a comparison chart in terms of advantages, applications, and working procedures.

What are LVDT and RVDT?

The difference between LVDT and RVDT mainly includes its definitions, advantages, differences, and key differences.

What is LVDT?

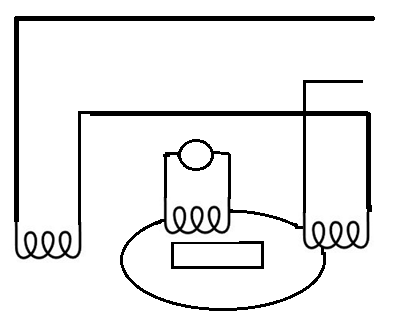

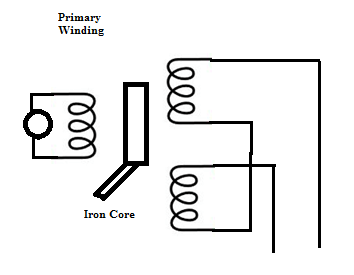

The LVDT is a transformer type which is converting linear displacement into that of electrical signals. This transformer is consisting of 2 secondary and 1 primary winding and each of the secondary windings is having an equal number of turns. Both windings of secondary are connected with each other in series. However, the primary winding has to be placed amid secondary windings.

The excitation of the primary winding is acquired through alteration of current while the soft iron core is in the middle of the secondary winding. The displacement is needed to be measured is always linked to that of the soft iron core. The AC source is being utilized for excitation purposes of the primary winding and the current is inducing flux in primary winding through mutual induction. In such transformers, at the null point, primary flux is equal at both secondary and primary windings. There is an equal magnitude of emf in secondary windings and the net output is zero at the null point.

However, the output of secondary winding is highly dependent on the magnitude of flux which is linking the winding. The emf variation in the secondary winding in accordance with the movement of the iron core.

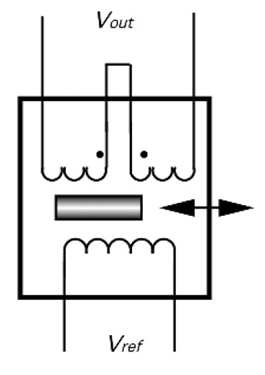

What is RVDT?

The RVDT is also a type of transformer which is operating in the same manner as LVDT, however, the only exception is the use of the rotary ferromagnetic core. The major utilization of RVDT is to measure angular displacement and linear range of its measurement is approximate +- 40 degrees. At the time when AC is utilized then the output is linear throughout a certain range. The transducer of the rotary is sensing angular displacement and core is always placed amid secondary and primary windings and displacement which is to be calculated is linked to the shaft of the core.

Comparison between LVDT and RVDT

Parameter | LVDT | RVDT |

| Measurement Factor | Linear movements | Angular movements |

| Measurement Range | It is between | Linear over range of approximately |

| Shape of the core | Rectangular | Cam-shaped |

| Sensitivity | Equivalent to 2.40 mV /V/degree of rotation | Equivalent to 2 to 3 mV /V/degree of rotation |

| Input Voltage | It varies from 1V to 24V at a frequency range of 50Hz | Minimum 3V with a frequency range of 400 Hz to 20KHz |

| Applications | Used to measure weight, pressure, and other product inspection places | Mainly used in controlling units such as fire monitoring, antenna, and radar systems |

Key/Main Differences between LVDT and RVDT

The key/main differences between LVDT and RVDT are as follows,

- An LVDT, the cylindrical soft iron core is used to calculate the linear displacement, whereas cam-shaped rotary ferromagnetic core in RVDT for angular displacement measurements.

- The sensitivity range of LVDT is high, ranging 2.4mV per the voltage and per degree change in moments and 2 to 3 mV per voltage per degree rotation in RVDT.

- The RMS input voltage of LVDT and RVDT is 1-24V and 3V, respectively.

- A phase sensitivity detector connected at the output of LVDT is used to judge and calculate the direction of movement. In RVDT, the angular position is measured by comparing the difference between two output voltage and angular variations.

- The measuring displacement of LVDT and RVDT is +/- 100mm and 40 degrees, respectively.

Even though designing an RVDT and LVDT is simpler in structure, there is a requirement of great effort to measure non-linearity errors, threshold factor, and maximum precision values. Ferromagnetic materials are used to achieve magnetic shielding properties. The bobbin-less coils (free-standing coils) are leveraged to reduce the size of the LVDT gage head and exact coil positions within the model and the nonlinearity difference range should be in the range of 0.15% and 0.35%.

In most of the scenarios, there exists a trade-off between the primary voltage and the secondary impedance due to eddy current loss in the core. To overcome this drawback, the carrier frequency of LVDT and RVDT is approximately set to 2.5-5 kHz and 5-10 kHz respectively.

In general, LVDT and RVDT are used in a wide range of applications and scenarios where there is a requirement of systems with negligible wear and tear properties. Several types of research are carried out in a similar field to determine its advantage using external sources, and the future prospect deals with the utilization of LVDT and RVDT at its utmost level.