We know that electromotive force & current will generate when the magnetic flux is flowing throughout a coil changes. Similarly, once the magnetic flux is passed throughout a solid coil, then it will induce current & emf. So the induced current through the conducting body is called the eddy current. This current is named an eddy current because of the flow of the current look like eddies/whirlpools. This article discusses an overview of an eddy current – working with applications.

What is Eddy Current?

Eddy current definition is; the flow of current that is induced in any solid conducting body once the magnetic flux is supplied throughout it. Once the conductor encounters a change within the magnetic flux, then the free electrons present in the conductor will experience a magnetic force. So the magnetic force effect on the free electrons will move in the eddies or small loops form which is called the eddy current.

The main properties of eddy currents are; these are only induced within the conducting materials, they are distorted by different defects like corrosion, edges, cracks, etc. So this is used in aerospace, power & petrochemical-based industries for detecting damages & metal cracks.

Eddy Current Working Principle

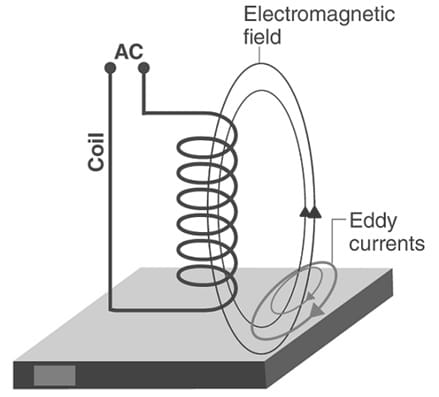

The eddy current working principle is to generate eddy currents within a conductive material. So this can be achieved by connecting a coil to an AC generator which drives an alternating magnetic field. The flow of current induced by this magnetic field in the conductive material will generate a magnetic field by itself in opposition to the alternating magnetic field based on Lenz’s law.

Eddy Current Working

This current is induced current within a conductor whenever a conductor is simply exposed to a varying magnetic field because of the relative motion of the conductor as well as the field source or because the field changes with time. So this can cause electrons to flow in a circular form in the conductor’s body. These circulating currents (eddy currents) have inductance & induce magnetic fields. So these fields can cause attractive, propulsion, repulsive & drag effects.

When the applied magnetic field is stronger or the electrical conductivity of the conductor is greater, or the field changes faster, then the developed currents are greater that are developed & produced fields are greater. This current generates heat & electromagnetic forces like all electric currents. The generated heat can be used for induction heating whereas electromagnetic forces are used for creating movement, levitation, or to provide the very strong braking effect.

Eddy Current Theory

The induced eddy current’s magnitude is measured by using Faraday’s law of magnetic induction. Based on the second law of Faraday’s, the emf induced can be written simply as the speed change of magnetic flux with respect to time will give an increase to induced e.m.f within the conductor,

So mathematically it can be written as

Emf = E = -dΦ/dt

Where,

‘Φ’ is the magnetic flux supplied throughout the conductor.

The negative (-ve) sign indicates the magnetic flux direction & it is determined by the Lenz law.

The induced current within a conductor whose resistance ‘R’ can be measured with ohm’s law, then we can get

I= e/R

Where,

‘e’ is the induced emf within the good conductor when magnetic flux changes

‘R’ is the conductor’s resistance.

By substituting the induced emf value within the above equation, then we can get

I = – dΦ/dt/R => -1/RdΦ/dt

The above equation is the induced current’s expression and the induced current’s direction is simply estimated through the Lenz law.

Eddy Current Braking System

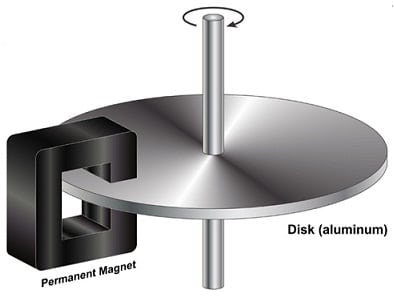

Eddy current braking system is an alternative to mechanical brakes with damage-free use in rollercoasters & high-speed trains. Not like mechanical brakes, this brake system relies on electromagnetism to prevent moving objects because mechanical brakes are based on kinetic energy & friction.

Eddy current is created once a conductor passes through a magnetic field, generating opposing forces that turn within the conductor. Based on Lenz’s law, the flow of current generates a magnetic field that is in opposition to the magnetic field that produced it, and hence these currents are an inverse response to the magnetic field source. As a result, this reaction between electromagnetic forces occurs to be ideal for clean deceleration.

Eddy Current Braking Systems

Eddy current braking system has many advantages compared to mechanical brakes. It is perfect for many types of machinery because of a lack of physical contact between components, so it makes eddy current brakes extremely low maintenance. Eddy current brakes have physical & economic benefits associated so these are the best option for mechanical engineers.

For these brake systems, Electromagnets are normally used instead of permanent magnets because the magnetic field power & braking effect can be changed. One main drawback with these brakes is that they cannot provide a holding torque. Thus, they are frequently used in conjunction with typical mechanical brakes. Eddy current brakes are used in high-speed trains, exercise equipment, industrial equipment, power tools, etc.

Eddy Current Loss

If an eddy current ‘I’ of magnitude supplies throughout a core lane of resistance ‘r’, then it will dissolve energy in the heat form based on the power equation = I2R. As this signifies energy being spent for no functional purpose, which is considered as an eddy current loss or sometimes it is known as iron loss.

In other words, the loss of heat caused by eddy currents within the magnetic material is known as eddy current loss. The other loss that occurred within the magnetic material is known as hysteresis loss. So combining both losses like eddy current & hysteresis are known as iron loss, constant loss & magnetic loss.

The eddy current loss is simply proportional to the Square of the eddy current & core resistance. So, Eddy Current loss formula = K * I^2 R. Here, ‘K’ is the eddy current constant.

From the above equation, it is very clear that the flow of current is higher, and the loss will be higher. The cross-section area of the solid core is large, so it has lower resistance. Based on Ohm’s Law, when the resistance is lower, the flow of current within the circuit will be higher.

I = V/R

Thus, the magnitude of the current will be extremely high which leads to maximum eddy current loss.

Mathematical Expression

It is hard to find out the eddy current loss from the values of resistance & current, although by the experiments, the power loss of eddy current within a magnetic material is given as below shown equation. So, the mathematical expression for eddy current loss calculation is given below.

Eddy current loss, Pe = KeBmax^2f^2t^2V watts

Where ‘Ke’ is constant.

‘Bmax’ is the maximum flux density within Tesla.

‘f’ is the frequency of magnetic reversal within Hz.

t = thickness of laminations in mm

‘V’ is the volume of the core within M^3

The above formula or equation of eddy current loss is used in electrical machines like AC & DC motors and transformers to measure the eddy current loss.

How to Decrease Eddy Current Loss?

Eddy current loss can be reduced by simply reducing the current. So this can be done by increasing core resistance. This core resistance can be reduced by using thin lamination sheets within the core and by using high-resistive silicon (Si) steel for core material

The core material is simply designed with thin laminated sheets. So the lamination on sheets offers electrical insulation between two nearby sheets. The cross-section area of the thin sheet is smaller like R = ρL/A & thus it has more resistance. This large resistance will hinder the eddy currents’ path. So, the magnitude of current, as well as loss, will be reduced.

One more method to reduce the current & loss is by using a Cold Rolled Grain Oriented steel core which has high electrical resistance, so the eddy current will be reduced .

Advantages

The advantages of eddy current include the following.

- The process of Eddy current is very helpful in the inspection process. Eddy current is a non-contact inspection procedure that does not have an effect on the work.

- Inspection through this process is an accurate & very fast procedure.

- Less maintenance is required for its breaks.

- It can bring a machine running at maximum speed to stop quickly, safely & smoothly.

The disadvantages of eddy current include the following.

- The flux leakage occurs more in eddy current.

- The loss of heat is more.

- This process is not applicable to inspecting all kinds of metals.

- Precise inspection is not possible for complex designs.

Applications

The applications of eddy current include the following.

- Eddy currents are used in trains & roller coasters for magnetic braking.

- These are used in Electric power meters.

- These are used in Induction furnaces and damping within Galvanometers.

- This is used at home in electricity meters.

- These are used in an induction-based Furnace.

- These are applicable in cars for speed Indicators and also used in speedometers.

- Eddy current is used for identifying flaws in airplanes.

- This is used in an amusement park ride braking system, which allows for contactless & considerably smoother stopping.

- Eddy current effects are used for cancer treatment in medical equipment.

Know more about Moving Coil Galvanometer, Tesla Coil.

Know more about Magnetic Circuit MCQs, Watt’s Law MCQs.

Thus, this is an overview of an eddy current – working with applications. Eddy currents are induced within a conductive material through an alternating magnetic field because of electromagnetic induction. This is used in sorting materials, measurement & control of tube dimensions, etc. Here is a question for you, what is another name for eddy current?