The 20th century has seen many advancements in technology by inventing many new devices. This was also the era where researchers were making a shift from analog technology to digital technology. The size of many devices began to shrink from meters to millimeters and nano. One such development can be seen in the way monitor screens have been evolved. Displays have come a long way from being a bulky monochrome to slim UHD. One of the devices that played a crucial role in the design of monitor screens is the “Flyback Transformer”. Apart from many other applications, this device is well known for its usage in CRT.

What is a Flyback Transformer?

As the name suggests, the Flyback transformer is a special kind of electrical transformer. This transformer was made to generate high voltages. It is also widely known as “Line Output Transformer”. This transformer is highly used to control the horizontal movement of the electron beam generated in the cathode ray tube. The prominent quality of this transformer that sets it apart from other kinds is its ability to retain energy in its magnetic circuit. This transformer generates a sawtooth signal. But, unlike general transformers, it doesn’t depend on the input waveshape to generate a sawtooth output signal.

Why is it Called a Flyback Transformer?

Flyback Transformer got its name from one of its operations. The primary winding present in this transformer uses a low voltage sawtooth wave. This wave first gets straightened and then switches off abruptly, causing the electron beam to fly back from right to left on the display. Hence the name Flyback Transformer.

Construction

As every transformer. flyback transformer also has primary and secondary windings. Here, the primary winding is done around a ferrite rod. For secondary winding, an emulated wire is used. The secondary winding is done layer by layer around the primary. This is done to reduce the leakage inductance of the primary. Between the layers of secondary, Mylar film is added. This type of arrangement provides high voltage wire parts with high dielectric separation between them. Now, a ferrite frame is wrapped around this assembly, enclosing the magnetic field lines of the transformer. To increase the reluctance, the air gap is maintained between the rod and the ferrite frame. Eventually, this air gap helps in a string of energy in the Flyback transformer.

Circuit Diagram

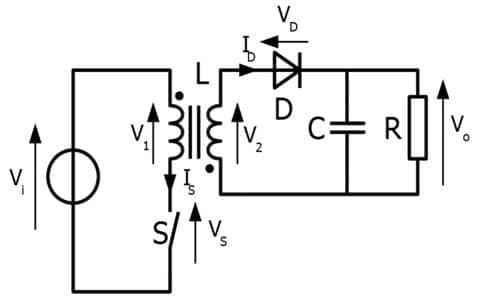

The below diagram shows the circuit for the flyback transformer. The primary components of a flyback transformer are

Flyback Transformer Circuit Diagram

- Primary Switch: A MOSFET mounted on a heat sink is usually considered as a primary switch of the transformer. Switches such as a bipolar transistor, GaN, SiC are also considered occasionally.

- Mutually Coupled Inductors: In a flyback transformer, the secondary winding is wound around the primary winding making them coupled inductors. This arrangement helps it in delivering high voltages up to 50Kv with higher frequencies.

- Output Rectifier: This helps in the transfer of energy stored in the magnetic core of the transformer to the load.

The unique construction of a flyback transformer with an air gap that can store energy makes it stand out from all other transformers.

Working

When the FET switch is closed, the current is supplied to the primary winding. At this stage, energy gets stored in the gap provided in the magnetic core of the transformer. The output rectifier is reverse biased, thus no current flows into the secondary winding when the switch is closed.

When the switch is opened, all the energy stored in the magnetic core gets transferred to the secondary winding, then to the load. At this stage, the current at the secondary winding reaches a peak. Then, when the switch is closed, current in secondary declines rapidly as all the current gets transferred to the load

If the switch is closed before all the energy present in the secondary moves to load, the current in the secondary never reaches zero. Hence, the Flyback transformer is said to be working in Continuous Conduction Mode (CCM).

When the switching is done after all the energy is transferred from secondary to load, the secondary current reaches zero. Hence, the Flyback transformer is said to be working in Discontinuous Conduction Mode (DCM).

Flyback transformers can be designed to work either in CCM or DCM or both. This transformer can operate in any of the above modes depending on the input voltage and load conditions.

Testing of Flyback Transformer

Bad design and poor quality of the materials used during the manufacturing of Flyback Transformer leads to damage of the transformer due to short circuit with 2 years of their usage. Some of the common problems found in Flyback transformer are

- Short circuit in primary windings causing no display, power blink.

- Shorted internal capacitor causing no display, power section will blow.

- External arcing to the ground.

- Internal arcing in the winding.

- breakdown at a full operating voltage

- Cracked Flyback transformer

- Voltage divider breakdown, causing blur display

- Short circuit between the primary and secondary winding

To test the problems related to the primary winding, a Flyback tester is used. This device identifies the faults in the primary winding by performing the ring test. To test the problems related to the internal capacitor, a normal analog meter, and a digital capacitance meter is used. A good capacitor must range between 1.5 nanofarad to 3 nano farad. Problems such as External arcing to the ground and internal arcing in the winding can be found by listening to the arcing sound generated by the transformer.

Applications of Flyback Transformer

Flyback transformers are of low cost, simple in design. This transformer can provide multiple output voltages. Applications of Flyback transformer is highly seen in Cathode Ray Tubes, Television monitors, Plasma Lamps, and similar types of equipment.

Please refer to this link to know more about Core Transformer MCQs.

For cathode ray tubes, high voltage is required to ionize the electron beam. This can be achieved easily with a smaller size, high voltage flyback transformer compared to the conventional transformers. These transformers work at higher frequencies. When used in televisions, they are used to generate a frequency of about 15kHz. When used in modern computer displays, it operates for frequencies ranging from 30KHz to 150kHz.

These transformers are often chosen for high voltage experiments due to their easy availability, simple operation, and high achievable voltages. What is the amount of voltage required by a large color TV CRT?