Hopefully, we are living in a world that revolves all-around digital trends and technologies. Just flickering a switch will provide power and we find the operation of many devices through a simple motor. Many of the household and commercial devices are included with mini motors and these days they gain more prominence because of their simple design, streamlined operation, and many other features. So, this article completely describes the concepts related to mini motors such as mini dc motor, its applications, the making of the mini-motor, and a few others.

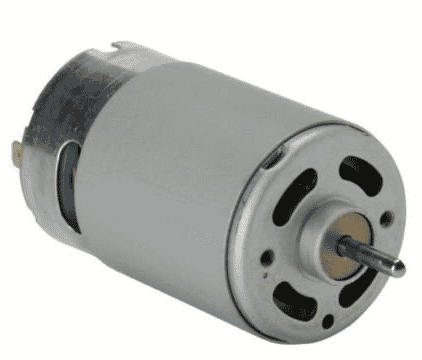

What is Mini Motor?

A mini or small motor is also termed as the electric motor where the fundamental functionality is to convert electrical energy to mechanical energy. Depending on the power availability, mini motors can be implemented in various applications where the minimal size and load enhance dependability and efficiency. Also, these small-sized motors are extremely comfortable and easier to be used for multiple purposes.

Mini Motor

How to Make a Mini Motor at Home?

The required materials for the making of the mini motor at home are:

- Paper clips

- Wire cutting pliers and strippers

- Mini battery

- Required size wood

- Staples, hot glue, staples

- Shielded wire

- Neodymium magnet

- A wire made of copper

The steps to be followed are:

Step 1

Take a copper wire of length 2 – 3 feet and start rolling the copper wire all across the battery. Note that to leave a gap of nearly two inches of wire at one coil edge. And also, the winding has to be so tight. Make sure to leave a wire length of 2 inches behind from your helix after rolling the copper wire around the battery 15 turns. Cover the trailing edges of the wire across the coil 3-4 times. This will create an exact balance for the motor.

Step 2

To gain good electrical association between the motor and battery, the two edges of the coil are completely enameled with sand. The more enameled, the better the electrical connection. First, start to sand off only one edge of the copper wire, then go with the other edge. The other side has to be properly enameled and this provides enhanced connection.

Step 3

In order to hold the coil, there has to be a rig and for this one has to build two small shelves through paper clips. Twist one edge of the paper clip into ‘L’ form, and the other end is bent in the shape to form a shelf. Next, fix the twisted paper clips on the 3 inches wooden board to check whether they are balanced and uniform. If not, do some changes to make them steady.

Step 4

Take an insulated wire of length 1 feet and also cut off your wire into half equal parts. Using wire strippers remove the plastic surface on both the edges of the insulated wire. Then cover the uncovered edge of the insulated wire across the shelves made of paper clips. Place the shelf along with the insulated wire on the wooden block using a staple gun.

Step 5

Now, place the neodymium magnet on the rig. The magnet has to be placed in the center position of the two shelves. Through hot glue, the magnet can be exactly placed and this keeps the magnet in a balanced position.

Step 6

Place the copper coil on the shelves so that the uncovered edges have to be in contact with paper clips. Then connect the exposed insulated wire to the battery. This creates spinning action for the copper coil and the motor action starts.

So, this is the simple procedure of making a mini motor at home.

Types of Mini Motors

Being suitable for many applications that are based on precise design; these mini motors have augmented reliability and performance. Few of the types of mini motors are:

Brushless Mini DC Motors

The prominent features of brushless mini motors are position and speed controllability is tremendous, increased torque density, and more operational life. The requirements of outstanding velocity and torque allow this device to be implemented for various purposes. Brushless are again classified as slotless and slotted mini motors where slotless motors make use of a tube-shaped coil-like ironless motor. And the slotted motors are constructed of stators. Even these motors hold the ability to perform sterilization activities.

Linear Stepper Motors

This kind of mini motors generates translational movement which results in delivering steadfast motion and cost-efficient solutions. Attaining linear motion inside of the motor reduces the complexity of designing and also lessens the points that are necessary for prospective operation. With the elimination of exterior parts, the entire efficiency of the motor gets easily increased. The ball bearing model offers prolonged life for the motor and facilitates greater load managing ability. Digital management allows the motor to be controlled just using a microprocessor having no requirement for a positional response.

Disc Magnet or Micro-Stepper Motors

Disc magnet motors deliver great dynamic performance. The very thin disc magnet provides enhanced resolutions. This generates increased acceleration because of minimal inertia and more top velocity. So, these magnet motors are suitable for applications that need quick incremental movement. The exceptional features in this type are:

- Minimal circuiting allows for fast speed of the motor and boosting ability

- The adjusted package provides quick movement in less time

- Reduced inertia shows excellent acceleration

- Extremely adaptable and it can be available is required diameter ranges up to 91 mm

The other types include

- Can Stack

- Surgical motors

- Ultra EC motors

Applications

The absolute features like compact layout, resistance, and streamlined programming allow various applications of mini motor and those are as below:

- Textile, and footwear domain

- Timber applications

- Plastic and rubber manufacturing

- Used in toys, and watches

- Printing domain

- Nautical purposes

- Bottling

- Used in electromechanical and motorized industries

- Applied for medical operations

- Hairdryers

So, these are a few of the mini motor applications

Project Ideas

People can develop various range of projects using these mini motors. Either in schooling or graduation, they can choose project ideas that are developed with mini motors. A few of the sample mini motor projects that can be developed are racing, water motor, water pump motor, dc air pump, generator motor, drone motor, fan motor, servo motor, gear motor, dynamo motor.

Know more about Difference b/w Motor and Generator.

This is all about the detailed concept of the mini motor which is also called a small motor. As because of this device features like enhanced consistency, efficiency, performance, quality, and design, these motors are extensively used in various applications and industries. In addition to these, gain a detailed knowledge of the detailed operation of the mini motor, its advantages, and more applications?