As we know that in the domain of electronics, capacitors are the most prominent devices which are extensively used in the design of various circuits. The key advantage of using a capacitor in electronic circuits is, its ability to store the electrical energy between its plates. These are the most considered components used for controlling the charge flow in the circuit. Capacitors along with devices like inductors and resistors come under the classification of passive components implemented in electronic apparatus. Even though the general capacitors are of integrated type, this article completely focuses on explaining various types of capacitors, their usage, symbol, and applications.

What is the Definition of Capacitor?

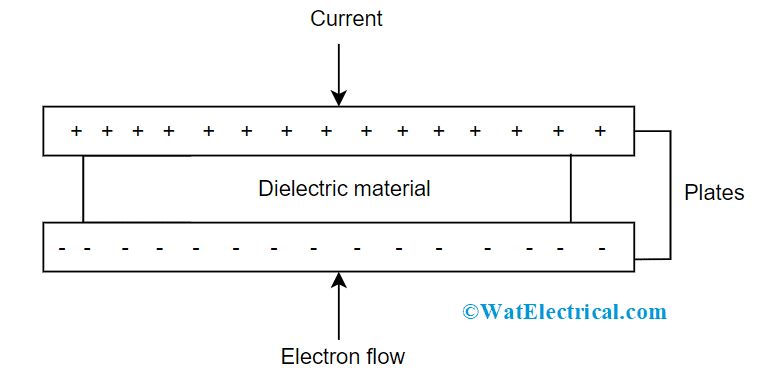

To be clear and accurate, a capacitor is a device that stores electric charge having one or more conductor pairs parted by an insulator/dielectric substance. The dielectric substances are the plates that are used for accumulating the charge where one plate stores positive charge and the other store’s negative charge.

The value of the capacitor is measured in the form of capacitance and this term is stated as the ratio between charge ‘Q’ and applied voltage ‘V’. This is represented as

Capacitance = Q/V

Where

‘Q’ calculated in Coulombs

‘C’ calculated in Farads

‘V’ calculated in Volts

So, this is the basic information of a capacitor. Now, let us know the capacitor types.

Types of Capacitors

There are multiple kinds of capacitors, and they vary in their style, format, manufacturing, length, girth, and many other aspects. But every type holds its own advantages and disadvantages. Therefore, it is more necessary to know how each type works so that the correct type of It can be selected for the required application.

There exist many variations consisting of whether it is fixed/variable, leaded, not-leaded, and many others. So, with all these considerations, capacitors categorization is shown in the below picture.

Today, a few of those types of capacitors are discussed below.

Dielectric Capacitor

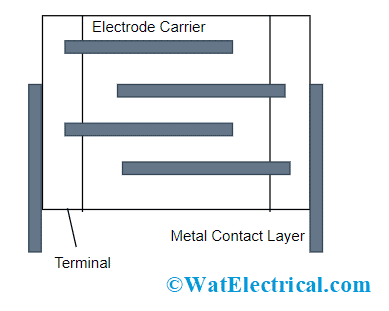

These capacitors come under the classification of variable types. Here, a continuous capacitance is needed for the device in order to tune transistor radios, transmitters, and receivers. These are multi-plated air-separated types that consist of both the static (considered as stator vanes) and movable plates (considered as rotor vanes). The rotor vanes rotate in between the fixed plates and the rotation defines the entire capacitance value.

When both the fixed and movable plated are tightly interconnected, then the device shows the maximum value of capacitance. These devices with high voltage tuning have more air space between the plates so that the breakdown voltage reaches some thousands of volts.

Film Capacitor

Film capacitors are also called film dielectric, plastic film, or polymer film capacitors. The benefit of using these capacitors in electrical circuits is they are economical. This device uses a delicate dielectric substance where the capacitor’s other side is metalized. Based on the necessity, film capacitors are set to be rolled into delicate films. The voltage of this device lies in the range of 50V to 2kV and the capacitance is in the range of 5pF to 100µF. The symbol of the film capacitor is shown below:

Film Capacitor Symbol

Based on the dielectric substance that is used in the device, these film capacitors are further categorized as:

- SMD style

- Radial style

- Heavy-duty snubber

- Axial style

Uses

- Utilized as precautionary capacitors and used in electromagnetic interference

- Employed in power applications

- They find use in enhancing the device’s power factor

- Used to protect devices from sudden and quick voltage spikes

Ceramic Capacitors

The name itself suggests that the device uses a ceramic type of dielectric substance. This dielectric offers characteristics like minimal loss factor, good stability level, but this is based on the type of ceramic that is used. In general, ceramic dielectrics do not provide high capacitance levels per unit volume and because of this the capacitance range between some picofarads to 0.1µF.

The availability of ceramic capacitors comes in usual leaded devices and feedthrough variations, but the most utilized form is surface mount capacitor which can be called MLCC (Multilayer Ceramic Capacitor).

And also based on the temperature range, temperature drift, and tolerance value, ceramic capacitors are further categorized into:

- Class 1 – Class 1 type of capacitors holds a high level of stability having more linear more properties.

- Class 2 – Class 2 types of capacitors possess high volumetric efficiency, but the levels of stability and preciseness are not good.

- Class 3 – Class 3 types of capacitors also possess high volumetric efficiency, but the levels of stability and dissipation factor are not good.

Uses

- The main usage of ceramic capacitors are in PCB boards and also used for high-density requirements

- Also used for many general applications as they have non-polarity behavior

- Employed in DC motors because they find useful in minimizing the RF noise levels

- Utilized in transmitter stations where resonant circuits are implemented

Polypropylene Capacitor

This capacitor comes under the classification of film capacitors, and here a very thin plastic film is used as the dielectric substance which is polypropylene. The main availability of these capacitors is as leaded components, but not widely employed when compared with other types of capacitors, but it has its own applications in various circuits.

The characteristics of polypropylene capacitors are very minimal dissipation factor, low capacitance, and a minimal level of moisture absorption.

Uses

PP capacitors are applicable mainly for multiple domains in electronics and the applications are:

- Used in precision timing and energy storage circuits

- Employed in lighting ballast systems

- They are also used in resonant and pulse discharge circuits that have high-frequency levels

- Used for audio applications as well

Variable Capacitors

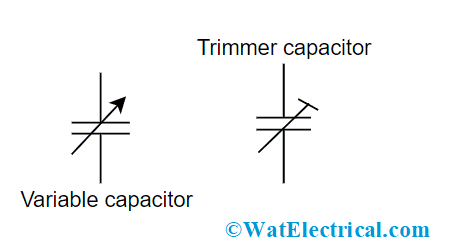

For variable capacitors, the capacitance value is altered by mechanical movement. In general, there is mainly two types of variable capacitors and those are:

Tuning Type – This is used for continuous tuning of the oscillator circuit in radio or else in another circuit that is tuned.

Trimmer Type – This is a small type of variable capacitor that is typically used for one-time oscillator circuit’s internal regulation.

In this type, the capacitors use mechanical structure in order to alter the distance in between the capacitor plates and to adjust the area of plate surface that overlaps. In variable capacitors, the dielectric substance used is air. The symbol of the variable capacitor is shown below:

Different Types of Capacitors in Variable Type

Electrolytic Capacitors

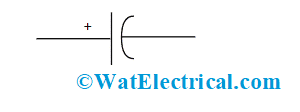

The usage of electrolytic capacitors is mainly in their high capacitance values. Here, a semi-liquid kind of electrolyte solution in a type of cream/jelly is used as a cathode which means the second electrode. The dielectric substance which is used here is a thin oxide layer. As because of the minimal thickness of the insulating substance, capacitors having high capacitance values can be designed where the spacing between the plates is also minimal. The symbol of the electrolytic capacitor is:

Symbol of Electrolytic Capacitor

In this type of capacitors, mostly all of them are polarized in nature which corresponds to that DC voltage which is provided to the terminal should be of appropriate polarity. In case of incorrect polarity, the insulating oxide layer gets breakdown and results in damage to the device.

Electrolytic capacitors are usually utilized in DC power supplies because of their high values of capacitance and also their minimal size assists in decreasing the levels of ripple voltage. But the drawback of using these capacitors is its minimal voltage rating.

The classification of electrolytic capacitors is

- Aluminum Type – Here, aluminum oxide is used as dielectric material

- Tantalum Type – Here, tantalum pentoxide is used as dielectric material

- Niobium Type – Here, niobium pentoxide is used as dielectric material

Uses

- These are mainly used for high capacitance applications

- Employed as filtering equipment in order to lessen the ripple voltage

- Used in audio amplifying devices to decrease noise levels

Silver Mica Capacitor

These capacitors possess increased precision, reliability, and stability. These are obtainable in minimal values and are mainly implemented at high-frequency levels, increased Q values, and minimal capacitor variation. The benefits of using silver mica capacitors are:

- Increased stability as the capacitive distance is minimal

- Airtight surrounding eliminates the complication of plates corrosion and oxidation

- Exhibits high capacitance per unit volume

- The devices can function without having any clamping mechanism

Even, these capacitors have more advantages, they are not more employed due to their high price and heavyweight. Using the extremely high level of compositional change in the raw substance makes the device more expensive. Whereas circuit manufacturers use silver mica capacitors for high power purposes like amplifiers, RF transmitters because other ceramic/porcelain type of capacitors does not hold the ability to tolerate high powers and heat.

The functional voltage range lies between 100 V to 10kV, the capacitance value lies between some pico Farads to a few nano Farads and the temperature coefficient is 50ppm/0C.

Paper Capacitor

This is also signified as a fixed capacitor where the dielectric substance that is used is paper and here the amount of accumulated charge is constant. The device has two plates and a paper that is positioned in between the two metallic plates. The symbol of the paper capacitor is shown below:

Paper Capacitor Symbol

Uses

- Employed for the purposes of noise filtering, and used in coupling/decoupling of systems

- These are utilized to provide additional power for amplifiers and used in audio systems

- Paper capacitors are also used in sensors such as fuel level, humidity, and many others.

Please refer to this link to know more about Capacitor MCQs.

Comparison of Various Types of Capacitors

| Type of Capacitor | Dielectric Material | Relative Permittivity calculated at 1kHz | Highest Dielectric Strength |

| Class 1 ceramic | Paraelectric | Ranges between 12 – 40 | Less than 100 |

| Class 2 ceramic | Ferroelectric | Ranges between 200 – 14000 | Less than 35 |

| Paper | Paper | Ranges between 3.5 – 5.5 | 60 |

| Aluminum Electrolytic type | Al2O3 | 9.6 | 710 |

| Tantalum Electrolytic type | Ta2O5 | 26 | 625 |

| Glass | Glass | Ranges between 5 – 10 | 450 |

| Vacuum | Vacuum | 1 | 40 |

| Supercapacitors | Helmholtz double layer | 5000 | |

| Film capacitors | Polytetrafluoroethylene | 2.0 | 250 |

| Mica capacitors | Mica | Ranges between 5 – 8 | 118 |

So, this is all about the concept of various types of capacitors. This article has provided a brief on multiple types such as ceramic, electrolytic, paper, variable, mica, and many other types of capacitors. Also know, what are the other types such as Power film type, double-layer, and many others?