Transformers are typically used to step down or step up voltage levels in AC circuits, and they operate based on electromagnetic induction. When transformers are connected in series, each transformer’s primary winding is connected in series with the previous transformer’s secondary winding. The secondary winding of the first transformer is connected to the load, and the primary winding of the last transformer is connected to the power source. In electrical circuits, a “transformer in series” refers to a configuration where multiple transformers are connected in a series arrangement. Connecting transformers in series is not a common practice in most power distribution systems or practical applications due to several reasons, primarily related to efficiency, complexity, and cost. This article gives brief information about a series transformer or transformers in a series and its effects.

What is a Series Transformer?

A series transformer, also known as an “auto-transformer,” is a type of transformer that consists of a single winding (coil) of wire that serves as both the primary and secondary winding. Unlike a traditional transformer with separate primary and secondary windings, an auto-transformer has a portion of its winding shared between the primary and secondary sides. The shared portion is called the “common” or “series” winding.

Series transformers are commonly used in applications where a small voltage change or adjustment is required. They are more efficient and cost-effective than traditional transformers with separate windings because they use less copper and have lower losses. However, they have certain limitations and are not suitable for all applications.

One significant limitation of series transformers is that they do not provide electrical isolation between the input and output sides. In other words, the output voltage is directly related to the input voltage, and there is no galvanic separation between the two. As a result, any disturbance or fault on the primary side can be directly transferred to the secondary side, which can be a safety concern in some situations.

Transformer in Series Wiring Diagram

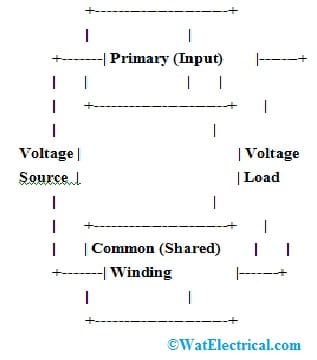

A series transformer wiring diagram shows the connections of a series or auto-transformer, which consists of a single winding serving as both the primary and secondary winding. The diagram will illustrate the tapping point on the winding and the input and output connections. Here’s a simplified representation of a series transformer wiring diagram:

Transformer in Series Wiring Diagram

In the above diagram, the left side represents the primary side of the series transformer, where the input voltage source is connected. The right side represents the secondary side of the series transformer, where the output load is connected.

The common or shared winding is represented in the middle, serving as both the primary and secondary winding. To adjust the output voltage, the tapping point on the common winding can be changed.

Moving the tap closer to the primary end increases the output voltage while moving it closer to the secondary end reduces the output voltage.

Connecting transformers in series means linking the primary winding of one transformer to the secondary winding of another.

This configuration is typically used when you need to achieve a higher voltage output than what a single transformer can provide. It’s important to note that this series connection doesn’t refer to the traditional primary-to-primary or secondary-to-secondary connection found in parallel transformers; it’s a specific arrangement to obtain a cumulative voltage.

When transformers are connected in series to increase the voltage, they are referred to as “boosting” or “step-up” transformers. These transformers are designed to raise the input voltage to a higher output voltage level.

Transformers windings series” can refer to transformers connected in series to achieve specific voltage transformations or to a specific type of transformer called an auto-transformer, which has a shared or series winding for voltage adjustment.

The series transformer function is to step down or step up the voltage level. When multiple transformers with appropriate turn ratios are connected in series, the total voltage transformation is the product of the individual turn ratios. This is useful in various applications, such as power transmission and distribution, where long-distance transmission requires high voltage to minimize losses.

Transformers in Series and Parallel

Transformers can be connected in both series and parallel configurations, each serving different purposes in electrical systems.

Transformers in Series

When transformers are connected in series, their primary and secondary windings are connected in a cascading manner, so the output of one transformer is connected to the input of the next transformer. The primary purpose of connecting transformers in series is to achieve a specific voltage transformation that cannot be achieved by a single transformer alone.

When transformers are connected in series with appropriate turn ratios, the total voltage transformation is the product of the individual turn ratios. For example, if you have two transformers with a turns ratio of 1:2 connected in series, the output voltage will be twice the voltage of a single transformer. Series transformers are often used in power transmission and distribution systems to step up or step down the voltage for efficient long-distance power transmission.

Transformers in Parallel

When transformers are connected in parallel, their primary windings are connected together, and their secondary windings are connected together. The primary purpose of connecting transformers in parallel is to share the total load current, providing a higher power capacity and redundancy.

When transformers are connected in parallel, they share the total load current proportionally based on their individual impedance. This allows for the combined transformers to handle a higher load capacity than a single transformer. Parallel transformers are commonly used in power distribution systems and industrial applications where high power capacity and reliability are required.

Effects of Connecting Transformers in Series and Parallel

Connecting transformers in series and parallel can have different effects on their overall operation, voltage transformation, and current handling capabilities.

- When transformers are connected in series they do not provide electrical isolation between the primary and secondary sides, which can be a limitation in specific applications where isolation is required, the current flowing through all transformers will be the same, and they may experience slightly reduced voltage regulation due to load imbalances and the shared winding nature of auto-transformers.

- When transformers are connected in parallel, they have the same voltage across their primary and secondary windings, they provide electrical isolation between their primary and secondary sides, and they share the total load current.

- Series-connected transformers are mainly used for voltage transformation and voltage adjustment (in the case of auto-transformers), while parallel-connected transformers are employed to increase current handling capacity and improve load sharing.

Advantages & Disadvantages

The advantages of the series transformer are;

- It is very efficient mainly for a high range of frequency.

- It prevents iron loss & condensed flux leakage.

- This transformer provides very good mechanical strength.

The disadvantages of transformer in series or series transformer are;

- The efficiency losses, complexity, cost, isolation, and safety.

- The size of this transformer can become high.

- The available power will slightly decrease based on the transformer efficiency.

- The amount of power required is high.

- It is not applicable outdoors.

- These transformers can be noisy.

Applications

The applications of transformers in series or series transformers include the following.

- Voltage regulation.

- Dimmer switches.

- Power transmission & distribution systems.

- Audio equipment.

Can Transformers Connect in a Series?

The transformers are typically not connected in series in power distribution or electrical circuits.

Why are Windings Used in Transformers?

Windings are an essential component of a transformer, and they serve a crucial purpose in the process of electromagnetic induction, which is the fundamental principle behind how transformers work.

What Happens When two Transformers are Connected in Parallel?

When two transformers are connected in parallel, they distribute load, offer redundancy, reliability increases, and can improve overall system efficiency.

Please refer to this link to know more about Power Transformer.

Thus, this is an overview of transformers in series, connection, working, and their effects. In series transformers, the voltage can be divided but the current will be the same. Thus, if there is above single primary winding, the voltage supply will be divided evenly at the input terminal within all the windings however the current will remain the same. If we desire to obtain double the voltage at the output, then we two secondary windings need to be connected within a series. It’s essential to design electrical systems carefully, and in most cases, the best approach is to use appropriate-sized single transformers or parallel-connected transformers to meet the specific voltage and power requirements while maximizing efficiency and reliability. Here is a question for you, what is a step-up transformer?