Autotransformer is a single winding transformer that works on the principle of Faraday’s Law of electromagnetic induction. Mostly used in low voltage range, for industrial, commercial and laboratory purposes. Also known as variac, dimmer stat, etc. autotransformer can be single and three-phase. Due to single winding, autotransformers have fewer losses, more efficient and robust. By taking tapping on the secondary side, a wide range of voltage can be obtained. In some applications, they are also connected to converters for rectifying the output AC voltage.

What is Autotransformer?

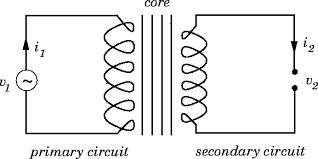

The principle of the autotransformer is the same as two winding transformers. It works on the principle of Faraday’s Law of electromagnetic Induction, according to which whenever there is a relative change in magnetic field and conductors, an emf is induced in the conductors. Consider a two winding transformer shown below

Transformer

When an alternating voltage is applied to the primary winding, it induces an emf in the primary winding due to the alternating nature of the magnetic field created due to AC supply and static conductors. According to Faraday’s Law of electromagnetic induction, there must be relative displacement between field and conductors, and in this case, the field is alternating and conductors are constant. Because of which an emf is induced in the primary winding of the transformer.

Induced emf in the primary winding creates an alternating flux in the primary winding. Flux links the secondary winding of the transformer by passing through the core of the transformer. This is called mutual induction. An emf is induced in the secondary winding. And based on the number of turns on secondary winding, the magnitude secondary induced emf is calculated.

Autotransformer Working Principle

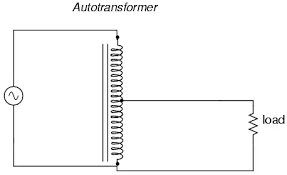

Now consider the autotransformer circuit diagram shown below. As compared to two winding transformers as shown in Figure 1, Autotransformer has single winding. When an alternating supply is given to the primary circuit, because of Faraday’s Law of electromagnetic Induction, an emf is induced in the primary part. Since the magnetic field is alternating in nature, and conductors are stationary.

Autotransformer

The induced emf in primary produces a flux, which is called as primary winding flux. This flux links the secondary winding and induces an emf on secondary winding due to mutual induction. Hence emf is transferred in the secondary winding. Based on a number of turns on the secondary side, the magnitude of induced emf is determined.

Autotransformer Working

The emf equation of induced emf is given as

E=4.44∅Nf

This can be generalized for both primary winding emf and secondary winding emf. If we take ratio we get as

E1/E2 =N1/N2 =k

It could be seen that the magnitude of induced emf is directly proportional to a number of turns. If a number of turns are greater on the secondary side, it is called a step-up autotransformer. If several turns are less, it is called a step-down autotransformer. It is also observed that, in two winding transformers, flux links the secondary winding through the core of the transformer. There is no electrical link between primary and secondary. For that reason, the transformer is called as electrically isolated but magnetically coupled device. But for an autotransformer, there is electrical isolation. There is only one winding. For this reason, autotransformer is called as electrically and magnetically coupled device.

The nature emf induced as shown in above is statically induced emf. If the source is alternating and conductors are constant, in that case, nature induced emf is statically induced emf. If conductors are rotating and the magnetic field is constant in that case emf induced is dynamically induced emf. In the transformer and autotransformer, induced emf is statically induced emf. In the case of DC generators, induced emf is dynamically induced emf. For statically induced emf, the direction of currents is given by Lenz’s Law. In the case of dynamically emf, it is given by Fleming’s Right Hand Rule. Hence in autotransformer, the direction of induced emf is given by Lenz’s Law.

Also in two winding transformers, energy from primary to secondary is induced through induction, but whereas in autotransformer, energy is transferred through both induction and conduction. It is to be noted that, for induction of emf on the primary side, as per Faraday’s Law of Electromagnetic induction, there must be relative change between the magnetic field and set of conductors. For this reason, we get AC voltage on the primary side, which is alternating in nature. If we give, DC, then autotransformer or two winding transformers will not operate, because of the constant nature of supply. Hence we say that the transformer does not operate in DC. In fact due to low resistance of primary winding, when DC supply is given, due to large currents, the winding will burn.

Properties of Autotransformer

The properties are

- Auto Transformer is electrically and magnetically coupled device

- In Autotransformer, power is constant

- In autotransformer, overall flux is constant

- In autotransformer, frequency is constant

- Voltage and current vary based on a number of turns.

- Autotransformer is also called a phase-shifting device

- The losses are less in autotransformer as compared to two winding transformer due to single winding

- The efficiency of the autotransformer is more as compared to two winding transformers

- Both iron and copper losses are less an autotransformer.

Auto Transformer Construction

A transformer basically consists of two parts

- Conductors

- Core

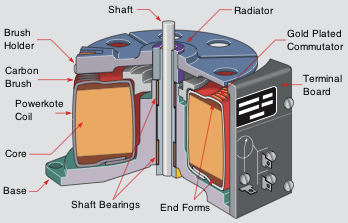

The conductors in the autotransformer are made up of copper. They are of low resistance. The copper conductors are insulated with each other. The material used for insulation is impregnated paper, mica, etc. The insulation also helps in reducing eddy current losses. The winding is wound around the core. For a single winding transformer, the requirement of copper is less as compared to two winding transformers.

auto-transformer-construction

To transfer flux from primary to the secondary, core is used. The core is made up of magnetic material like silicon steel, CRGO steel, etc. CRGO steel is the most efficient material for core, as it has the least hysteresis losses. The role core is to transfer flux from one part of winding to other parts.

Other important parts as shown in figure 3 are bearings, brushes, terminal boards, etc. The parts shown are used for dimmer stat basically used for laboratory purposes.

Advantages and Disadvantages of Autotransformer

The advantages are

- Losses in Autotransformer are less

- The efficiency of the autotransformer is more

- Copper Requirement is less

- The core requirement is less

The disadvantages are

- Autotransformers cannot be used for high voltages. Since any discontinuity in the primary winding would result in complete primary voltage on the secondary side, therefore it cannot be used for high voltages

- The insulation requirement is more. Since autotransformer is both electrically and magnetically coupled, the requirement of insulation is more.

- Because of common winding, a neutral connection is difficult.

Applications of Autotransformers

The following are the applications of autotransformers.

- Autotransformers are used for starting induction motors

- Auto Transformers are used for voltage regulation

- Autotransformers are used for laboratory purposes.

- Autotransformers are used in many industrial applications like paper mills, factories, etc.

FAQs

1). Does Auto Transformer work in DC

No, the autotransformer cannot work in DC

2). Does autotransformer have two windings?

No, autotransformer has an only single winding

3). Is autotransformer an electrically isolated device?

No, autotransformer is electrically and magnetically coupled device.

4). Is the efficiency of autotransformer more than two winding transformers?

The efficiency of the autotransformer is more than two winding transformer

5). Do we use autotransformers for high voltage applications?

No, autotransformers are used for low voltage applications ( 420 V). Beyond that, special measures are taken while designing.

Please refer to this link to know more about Phase Shifting Transformer, Autotransformer Starter.

Hence, this is all about an overview of autotransformers like working, construction, advantages, and disadvantages. Mostly used for starting of induction motors, and laboratory purposes, autotransformers have efficiency up to 98%. They are rugged for application, less maintenance and more lifetime. Here is a question for you, why are autotransformers not suitable for high voltage applications?