Let us first understand what is a synchronous motor basically, it is an induction motor that rotates at a synchronous speed. Here again, the question arises what is synchronous speed, now the synchronous speed is the speed at which the magnetic field rotates, depending on the frequency. From the formula Ns=120f/p, we know synchronous speed depends on frequency and number of poles (Ns=synchronous speed, f=frequency and p=number of poles). Practically all induction motors except this motor have some slip(the difference between synchronous speed and actual speed)which does not exist in a synchronous motor.

Construction of Synchronous Motor/Synchronous Motor Design

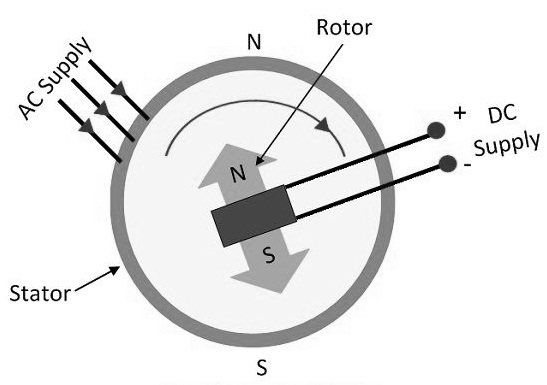

Unlike cage induction motor, the synchronous motor is provided excitation to both stator and rotor which becomes necessary in order to lock the poles together so that the rotor rotates at a synchronous speed.

synchronous-motor-construction

The field on the stator side is kept rotating (three-phase supply)and on the rotor, it is kept fixed (DC supply fed to the rotor through a pair of slip rings). Thus when the stator field rotates and the rotor is locked to the stator through the magnetic field it starts rotating at synchronous speed. Underneath is a diagram just to show the principle of this motor

The main parts of the construction of a synchronous motor as can be seen in the above figure are:

- Stator

- Rotor

- Exciter

- Winding both Stator and Rotor

- Slip ring (not shown in the above diagram)

The construction, however, varies depending on the type of this motor.

Please refer to this link to know more about Synchronous Motor MCQs

Working of Synchronous Motor

The working principle of a synchronous motor can be easily understood by thinking of two magnets locked with each other and if one(stator) rotates at a speed ‘Ns’ the other(rotor) will also rotate at the same speed ie. ‘Ns’.

Further, it will be understood as we go into the construction/design of this motor.

Types of Synchronous Motors

A broadly synchronous motor can be classified as:

- Non-excited (Rotor made of a permanent magnet)

- Separately Excited

For small applications, we may use a permanent magnet type rotor, due to which no separate excitation is required. But for industrial applications, all these motors are separately excited which gives control over power factor. Now the separately excited motors can further be classified depending on the method of providing excitation

- Excitation provided by a shaft mounted exciter

- Excitation provided by a static exciter using diodes/thyristors

In the case of shaft mounted exciter, it acts as a dc generator that feeds the motor rotor thru slip rings.

The excitation through static exciter is considered to be better as shaft mounted exciter gets eliminated and it provides better control.

Further, we can also classify a synchronous motor by the method of starting.

- Starting by a pry mover

- Starting as an induction motor

For details, we have to understand as to what are the starting methods of synchronous motor.

In order to happen a lock between the stator and rotor of this motor, we have to take the rotor near to synchronous speed say 90% of syn. speed. This can be done either by moving rotor by a pry mover or moving the motor as a slip ring induction motor with the help of a starter and switching on the excitation when the speed is achieved. All large synchronous motors are self-starting as an induction motor.

Let us understand what will happen when the load is applied to this motor. As load is applied the load torque angle of the rotor tends to change but due to the increase in stator current the stator magnetic force increases and does not allow it to change it’s(rotor) position with respect to stator thus maintaining synchronous speed.

However, the picture changes when a sudden heavy load is applied to the motor the sudden change in the load torque angle is not responded by the increase in stator current quickly enough and a hunting sets in before a study state is achieved. The result of this hunting is an oscillation in rpm and stator current both. This is known as hunting in a synchronous motor. However, hunting t can be caused by some more reasons as listed below.

- Sudden change in field current

- Sudden change in supply like voltage or frequency.

In order to minimize the effect of hunting, damping winding is provided on the poles of the rotor.

‘V’ Curve of Synchronous Motor

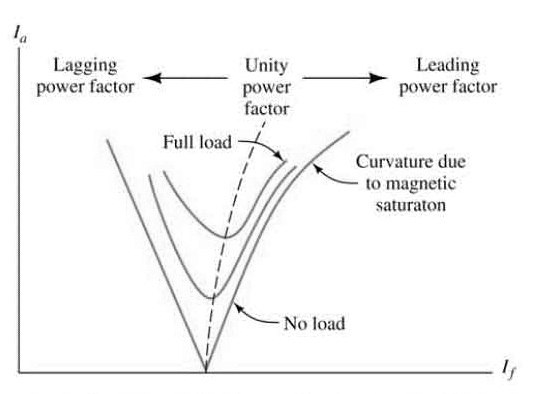

‘V’ curve of this motor is a curve plotted between field current (rotor) and the armature current (stator) at various loads. Because of its shape, it is known as the ‘V’ curve. In this motor, when we change the field current the power factor changes. This can be seen from the v curve, due to this as we increase the field current there is a decree in armature current and vice versa till the power factor is on the lagging side, but on further increase of field current, as the power factor goes on leading side, the stator current or the armature current starts increasing.

This change of power factor with field current finds a lot of use in heavy industry for power factor improvement. From the ‘v’ curve shown below, it is clear that at the unity power factor the armature current is minimum.

v-curve

Why Synchronous Motor is Not Self-starting?

The synchronous motor is not self-starting unless it is started as a wound rotor induction motor, because of the rapidly changing rotating magnetic field the rotor of the motor is not able to respond rapidly enough and the motor remains standstill. The poles of the rotor are almost simultaneously subjected to clockwise and anticlockwise torque thus not allowing the motor to move. By giving a start and increasing the speed to near synchronous we are reducing the relative speed between the rotating magnetic field of stator/armature and the physical motion of the rotor/field.

Applications

The applications of synchronous motor include the following.

- This motor offers two big advantages one is a constant speed motor with no-slip and second, it offers good control over the power factor.

In view of these advantages, it finds many applications in industry - For a very large power requirement, this motor is the only choice because if induction motor with cage or wound rotor is used the requirement of power factor capacitors is very high requiring very large space and also cost. One finds such applications in core industries like steel/cement etc.

- Due to its constant speed, it also finds some small applications in instruments/blowers, etc.

Thus, this is all about an overview of the synchronous motor which includes construction, working, types, V-curve, why it is not self-starting and its applications. Here is a question for you, what is the main function of synchronous motor?