The name of Hipot testing is taken from the “high potential” that they produce to achieve dielectric withstand & insulation resistance tests. So this testing has long been a standard process for different kinds of equipment. A lot of hipot testers also offer precise, low-resistance, high-current outputs and low-resistance measurements for testing ground bond integrity & ground resistance. At present, most advanced hipot testers use electronic source technology to promise compliance through IEC-61010, which clearly requires that the equipment of the voltage test shall be capable of maintaining the necessary voltage for a particular time period. This article provides brief information on Hipot Testing.

What is Hipot Testing?

An electrical safety test which is used to test a product/component to verify the efficiency of its insulation is known as Hipot testing. This test is also known as a dielectric-withstand test, high potential test, or pressure test. This dielectric strength test is helpful in deciding whether the wall of the ground handles the situation of a higher voltage or not. This test is also very useful in evaluating the insulation situation of test objects like transformers, relays, switchgear, bus-bar, generators, cables, lightning arresters, and many more.

This test can be performed from extremely low-voltage devices to very high-voltage devices. The hipot test is very helpful in determining terminal spacing issues, improper cable joints & terminations, crushed/nicked insulation, reduction within clearance and creepage, corrosive/ conductive contaminants, and braided shielding or stray wire stands.

Importance of Hipot Test

The Hipot test’s significance is, that it simply measures the electrical insulation range for the particular device. This test simply allows technicians to resolve whether the insulation handles transient over-voltages or not. This can be done for various devices over a particular amount of time. This test also helps in recognizing the issues with the insulation which is frequently finished with braided shielding, cuts, stray wire strands, tolerance errors, terminal spacing issues, corrosive contaminants, etc. There are many issues that occur during manufacturing like creepage or improper clearance distances which can be noticed through this testing. A Hipot test is essential to test the strain of an electronic device for security & excellence purposes.

Hipot Testing Procedure

The step-by-step procedure of Hipot Testing is discussed below.

- Step 1: First open switches/ CBs to separate the DUT from two ends

- Step 2: After that, a discharge rod is used to discharge all the conductors.

- Step 3: Place CAUTION labels or Barricades approximately the HV testing region

- Step 4: Attach Master Earthing Terminal (MET) of Hipot to a correct System Earthing

- Step 5: Attach the Operational Earthing Terminal to body earth or safety ground.

- Step 6: Make sure the correct connection.

- Step 7: The kit’s HV terminal must be allied to the conductive element of the test object.

- Step 8: Test all circuit phase conductors testing every phase to ground according to pre-determined time, current, and voltage setting.

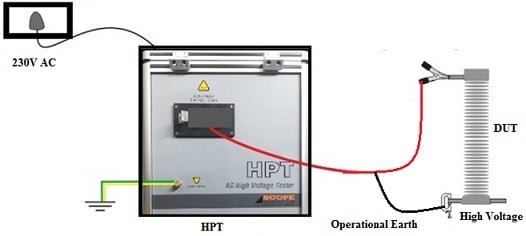

Hipot Connection to the DUT

When all these steps are followed, the following points are to be verified.

As an outcome of the voltage dissimilarity between the conductors, the flow of current would be monitored. No breakdown of either the solid insulation or air insulation must occur. In addition, the flow of current should not be above the 5mA peak. To PASS this test, the test object should be exposed to the smallest amount of stress of pre-decided Voltage for 1 min without any indication of breakdown. So in this way, Hipot testing can guarantee the security, excellence, and consistency of critical electrical equipment.

Hipot Test Formula

The Hipot test voltage is measured by using the following formula. Hipot voltages are mainly used for testing the insulation & confirm there won’t be an electrical breakdown.

To measure the hi-pot test voltage, a general rule of thumb is twice the working voltage + 1000V.

Hipot Test Formula = 2*(Working Voltage) + 1000V

For instance; if the working voltage is 120Volts, then the thumb test voltage rule will be 2*120 + 1000 = 1240Volts.

Generally, the hipot test is expressed in the form of AC/DC. So these hipot tests are equalized commonly using the following formula

Vdc = Vac (PEAK) = Vac(rms) × √2

The hi-pot test duration is normally 1 minute but according to the security standards, 1 to 2 secs are given for testing of the production line only if the voltage goes up by 20 percent as compared to the 1-minute test.

Hipot Testing for Cable

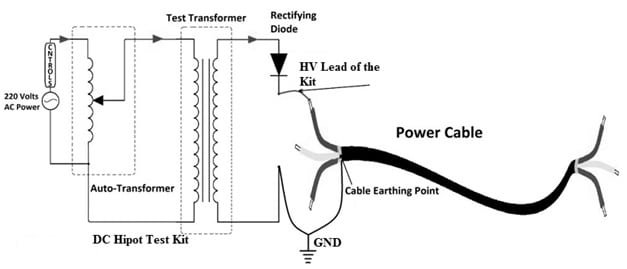

A Hipot test for cable is performed to ensure whether a power cable is well or not. This test is performed by using a Hipot Test kit which includes an auto transformer, test transformer some required components, and a power cable.

Hipot Test for Cable

Initially, the power cable which is to be tested is completely isolated from both ends. The cable’s all three phases are discharged with the help of earth rods so that it makes the cable free to work safely.

220V AC power is given as an input to the Autotransformer throughout a control box & the output of this transformer can be used for regulating the input voltage to the main windings of the transformer. Here the test transformer is used for increasing the voltage to the necessary test range.

In the above diagram, if the testing type is AC Hipot testing, then the terminal of the secondary winding for the test transformer is connected to the cable’s phase conductor. If the testing is DC Hipot testing, then the silicon rectifying diode can be connected simply with the test transformer’s secondary winding in series. The test transformer’s secondary terminal is connected to the cable’s phase conductor throughout the diode whereas the other terminal is connected directly to the ground with the cable armor.

As the connection shown in the above diagram, insulation among the Phase conductor as well as the ground is checked. Once the power cable is in service & charged state, then the cable’s armor is simply connected to the GND & the armor will be at ‘0’ potential.

So with the help of this connection, insulation between the phase conductor & also armor is also checked. So 220 volts of the input voltage is increased to the necessary test voltage that ranges from 6kv -60kv & the Hipot test is performed. The test voltage is increased based on the voltage & insulation level of the object to be checked.

A similar process is repeated for the power cable’s remaining two phases. In this manner, we could test the physical condition of insulation between phase & earth. In order to test the healthiness of insulation in between two phases, high voltage lead can be connected to one phase & other lead is simply connected to another phase & ground.

Similarly, the Hipot test for transformers is mainly used for determining whether a resistance welding transformer is stable electrically to be utilized within production. This kind of test is fairly quick & easy to complete in five minutes after being detached from the main power & the secondary. This test process tells us if there is any short internally, generally an insulation breakdown, otherwise if there is an open circuit within the secondary.

Difference between AC and DC Hipot Test

The difference between AC and DC Hipot Test includes the following.

AC Hipot Test | DC Hipot Test |

| AC hipot test can be done by simply providing a higher AC voltage on the test conductor & measuring the leakage current. | DC hipot is used to measure the cable’s insulation resistance by simply providing a higher voltage on the test device. |

| AC hipot test supplies are fairly large & heavy. | DC hipot test supplies are fairly small & less weight |

| AC Hipot test uses lower voltage. | DC Hipot test uses higher voltage. |

| This test uses AC voltage. | This test uses DC voltage. |

| The o/p current capability of the AC hipot test is higher. | The o/p current capability of this test is very low. |

| This test measures simply total current thus it does not give a precise measurement of leakage current. | This test gives a more precise leakage current reading by simply reading real current. |

| This test performs within both positive & negative voltage polarities. | This test does not execute polarity-based testing because it charges only insulation within a single polarity. |

| It is not cost-effective. | It is cost-effective. |

| It is not accepted by security agencies commonly. | It is accepted by security agencies commonly. |

| This cannot be utilized as a diagnostic test. | This can be utilized as a diagnostic test sometimes by comparing with other previous test results. |

Hipot Test Vs Megger Test

The difference between the Hipot Test and the Megger test includes the following.

| Hipot Test | Megger Test |

| The hipot test is a Dielectric Withstand Test used to measure the electric insulation level within a device by verifying whether that current will not supply between two particular ends under high voltages. | The Megger test is an electrical test used to determine the performance of insulation within electrical devices.

|

| A hipot test is also called a high potential test. | A megger test is also known as a megohmmeter test. |

| This type of test is used to test electrical insulation by simply providing high voltage for the equipment. | This type of test is used to test electrical insulation by simply providing low DC voltage to the equipment. |

| This test applies higher voltage for detecting insulation breakdowns or defects. | This test applies low DC voltage to determine the insulation resistance. |

| The voltage in this test is normally very high compared to the typical operating voltage. | The voltage in this test is normally very low compared to the typical operating voltage. |

| The hi-pot test verifies the sufficiency of electrical insulation for normally happening over-voltage transient. | This test is used to test insulation resistance. |

Safety Tips

Whenever working with any electrical instruments the output of that device is potentially unsafe voltages & currents so it is significant always to check that device regularly & encourage secure testing methods like; setting up a secure work area, training test operators correctly & setting up secure test processes.

So knowing and recognizing the safety hazards helps a manufacturer in protecting their workplace. The main safety points while doing the Hipot test are discussed below.

- Keep away unauthorized workers from the test region.

- Place the test station in a secure & orderly way.

- Do not create any illegal changes on the test instruments.

- Check any custom test fixtures and take the suitable ratings.

- Never touch the connections or product throughout a Hipot test.

- First, turn off the high voltage when any trouble occurs.

- Discharge any tested item correctly through DC before moving connections.

Advantages & Disadvantages

The advantages of the Hipot Test include the following.

- This test avoids injuries of electrical shock to operators.

- It decreases replacement costs or repair.

- It decreases the motor harm risk.

- It improves the life of the equipment.

- This test helps the manufacturers in identifying: corrosion or damaged insulation.

- This test usually involves either high potential testing or high voltage testing.

- The main benefit of this test is versatility.

- This test helps in detecting material & workmanship, insulation weak points, gap spacing in between conductors, dirt, contaminants & condensation within the insulation.

The disadvantages of the Hipot Test include the following.

- It measures the total leakage current only.

- It needs a big Hipot transformer because of measures the whole leakage current.

- It is not accepted always by security agencies.

- The DC hipot test cost is high as compared to the AC hipot test.

What causes hipot test failure?

Hipot test failure can lead eventually to an insulation breakdown.

What does a hipot test check?

The hipot test checks whether the ground wall handles an over-voltage or higher voltage situation or not.

Can high voltage damage cables?

If the level of voltage is adequately high such that it needs to arc in between conductors, it can harm cables.

Where is Hipot testing used?

Hipot testing is used to find cuts within the insulation, or crushed/nicked insulation. This type of testing can also be used on production lines in the manufacturing procedure.

Why dielectric test is performed?

The dielectric test is performed to decide the breakdown voltage on weak spots that occur by the effects of any type of dielectric. This test is used to verify compliance with the electrical security testing standards and confirm whether the component’s insulation adequately guards users against current shock.

Thus, this is an overview of Hipot testing (high-potential test) also called the Dielectric-Withstand test. This test is very helpful in evaluating the test object’s insulation condition like transformers, switchgear, relays, cables, etc. This test guarantees that current will not be supplied from one end to another end & specifies the capability of the insulation to resist overvoltage transient & high voltage. So, this test is an outstanding technique to notice any imperfection in an electrical product. To avoid the break of the electrical product’s insulation throughout operation can cause catastrophic injuries to man & machine, the Hipot test is performed generally during the manufacturing & installation procedure. Here is a question for you, what is the hipot testing voltage?