An asynchronous motor is a most extensively used motor in the industry, It is almost impossible to think of an industry without using this motor, due to its operation at the sub-synchronous speed it is known as an asynchronous motor. Having assumed such an important role it becomes imperative to study it in detail. This article discusses an overview of the asynchronous motor like its definition, working, construction, differences, and applications.

What is Asynchronous Motor?

Definition: An alternating current motor in which the stator is not synchronized with the rotor and is free to rotate at a speed less than the synchronous speed due to the slip. This is because the rotating magnetic field does not couple with the induced field of the rotor. In this motor, torque is generated when the rotor is not in phase with the stator and the current induced in rotor follows Lenz’s law.

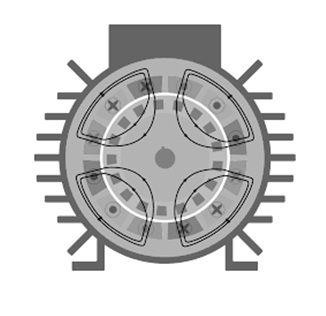

asynchronous-motor

However, if somehow the rotor gets aligned with the stator, it will create a locked rotor condition and torque will not exist. This motor always runs on a lagging power factor as the rotor lags behind stator. The power factor of this motor mainly depends on the design and load current, unlike the synchronous motor where it can be easily changed by changing the excitation current.

Working of Asynchronous Motor

This motor works on the principle of Lenz’s law which states that the direction of current induced in a conductor by changing the magnetic field is such that the magnetic field created by induced current opposes the changing magnetic field which produces it.

The changing magnetic field is created by the three-phase or splits phase current fed to stator winding and since this magnetic field cuts the rotor conductors producing induced current in the rotor which opposes the changing magnetic field of the stator. And thus, producing a rotating motion.

The working of this motor will be further as we discuss the construction and design.

Construction of Asynchronous Motor/Design of Asynchronous Motor

A three-phase asynchronous motor is available in two types

- Slip – ring type or wound rotor type

- Squirrel cage type or short-circuited rotor type

asynchronous-motor-construction

The first type ie, slip-ring-type consists of real winding in the rotor slots which is connected to the slip-rings. In this motor, we can introduce rotor resistance through the slip-rings and brushes. This enables us to alter the starting characteristics of the motor.

The squirrel cage type has rotor bars on the rotor which are short-circuited through rings on both sides. This type of motor has fixed starting characteristics that cannot be altered by adding any extra resistance.

The slip-ring type is maintenance prone as it has additionally slip-rings and brushes which are subjected to wear and tear. The other main parts of this are as under

- Stator

- Rotor

- Stator windings

- Rotor windings(for wound rotor type) and cage bars with shorting(for squirrel cage motor)

- In addition, this motor also has:

- Bearings

- End shields

- Motor fan with cover.

- Terminal box

The stator and rotor are made up of stampings of silicon steel this is done in order to reduce the losses due to eddy currents and hysteresis the stator can be connected to the three-phase supply either in delta or in star.

When we feed supply to the stator the current drawn gets divided into two components one being the excitation component and the other load component. The circulating magnetic field thus created produces circulatory motion in the rotor. All the parts listed above facilitate the rotational movement of the rotor.

Difference between Asynchronous Motor and Synchronous Motor

The basic difference between the two is the speed, the synchronous motor rotates at a speed which is the speed of a rotating magnetic field and is determined by 120 f/p where ‘f’ is the supply frequency and p stands for the number of poles.

Whereas an asynchronous motor has a speed which is always less than the synchronous speed due to slip. We can say that Nas = 120f/p-slip. Where Nas stands for asynchronous speed, or we can also say Nas<Ns, Ns is the synchronous speed.

The difference can be seen in various aspects:

| Specifications | Synchronous Motor | Asynchronous Motor |

Type

| Brushless motors, self-starting motors, and static exciter motors are the type of motors available in the synchronous range. | AC induction motor caged or wound rotor type is an asynchronous motor

|

Slip

| In a synchronous motor slip is zero | In this motor, a slip ring is not zero |

The Requirement of Additional Power Source

| In a synchronous motor, an additional power source is required to excite the motor | In the case of asynchronous motor, an additional power source is not required |

Slip ring and Brushes

| In a synchronous motor slip-rings and brushes are generally required | In this motor, slip-ring and brushes are not required.

|

Cost

| The cost of a synchronous motor is higher

| The cost of an asynchronous motor is lower. |

Efficiency

| The efficiency of a synchronous motor is higher | The efficiency of this motor is lower. |

Power Factor

| In this motor, the power factor can be changed by changing the excitation current | This motor always runs on lagging power factors which cannot be changed.

|

Speed

| In this motor, speed is independent of load | In this motor, speed reduces with the load.

|

Starting

| Synchronous motor is not self-starting, however, it can be started as a three-phase induction motor and after achieving near synchronous speed, it can be run as a synchronous motor.

| This motor is self-starting and can be easily started through suitable switchgear. |

Maintenance

| Synchronous motor is high in maintenance | An asynchronous motor is low in maintenance |

Torque

| Change of voltage does not affect torque of the synchronous motor | The torque of this motor is proportional to the square of the voltage.

|

Applications

| Synchronous motor is used where power requirement is high like in steel plants /Power plants etc. | These motors are used very widely for all smaller applications. This motor is also used as a synchronous condenser for power factor improvement.

|

Applications

- This motor finds widest applications in industry as it very reliable maintenance-free and cost-effective. Nearly 70% of power in the industry is utilized by these motors.

- One can hardly think of any industry which does not utilize these motors,

- Namely, Paper, metal, food, process industry like cement, fertilizer, Pumping, conveying, Etc

FAQs

1) What is the basic difference between synchronous and asynchronous motor?

The basic difference is asynchronous motor is a fixed speed motor (Synchronous), whereas an asynchronous motor speed is always less than the synchronous speed.

2) Why an asynchronous motor finds very wide use in the industry while the synchronous motor does not?

This motor is almost maintenance-free and cost-effective.

3) Can we change the power factor of an asynchronous motor?

No, the power factor of this motor cannot be changed, it will somewhat change with load only.

4) Can an asynchronous motor ever be run at a leading power factor as in synchronous motor?

No, this motor can never be run at a leading power factor.

5). What will happen to the motor torque in an asynchronous motor if the supply voltage varies?

In this motor, torque is directly proportional to the square of the voltage

6). what will be the effect of frequency change on an asynchronous motor?

The frequency change will affect the RPM of the motor to some extent.

7). Can we change the RPM of an asynchronous motor by any means?

Yes, we can change the rpm of this motor if we change the frequency and Voltage simultaneously keeping the ratio constant.

8). What will happen if an asynchronous motor is run in an overload condition?

If this motor runs in the overloaded condition it will draw excessive current and will cause motor burnout.

Thus, we can conclude from the above that an asynchronous motor is widely used in the industry and they offer many advantages over the other type of motors, with the advent of variable voltage variable frequency technology their role has further increased. These motors have evolved from low efficiency to very high efficiency. Here is a question for you, what is an induction motor?