All equipment has a limit to their operating range, a crane that is meant to lift 10 tones cannot lift 20 tones and if we try to do it, it will not only be unsafe, it will damage the crane itself. This analogy can exactly be applied to electrical equipment. Every electrical equipment is designed to specified load (current) and any overloading will meet the same fate as the crane. A tendency to increase output unknowingly increases the load beyond its capacity and the capacity of the feeding system making it unsafe. Moreover, since electrical parameters are always dynamic and flexible it becomes imperative to use overload relays with electrical equipment where ever possible. Here we will limit ourselves to overload relay about electrical equipment like motors, transformers, etc.

What is the Overload Relay?

Definition: Relay is a device that is supposed to operate under certain condition and if it operates under overloading conditions it is known as overload relay in electrical terminology. An overload relay is a device used to trip/indicate a condition of overload (over current) in electrical equipment and thus protect it. We can also call it an overload protection relay.

Overload Type Relay

Overload Relay Working/Functioning

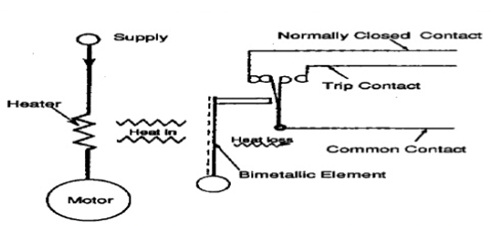

A thermal overload relay generally uses a strip which is made from two dissimilar metals (metals with different coefficient of expansion) Which are heated thru a small heating coil by the current going to the motor or any other appliance. The heater is designed to take only the permitted current. If the current exceeds the heat that is generated bends the bimetal strip due to the difference in expansion. Due to this bending, an actuating/trip lever gets operated and generates a trip command to the motor, thus protecting it. The distance between the trip lever and the bimetal strip is adjustable giving a range of trip settings.

In a three-phase motor, these relays also have a built-in feature that actuates the lever even when there is a large differential between the phase currents protecting the motor against single phasing also.

Overload Relay Types

We can have many types of overload relays but the most extensively used are:

- Thermal overload relays.

- Magnetic overload relays.

- Electronic overload relays

We shall take-up each one by one.

Thermal Overload Relay

As these relays are the most common ones, we shall be discussing them in detail.

Thermal Type

The flow of current in any conductor causes the generation of heat and the amount of heat thus generated depends on the conductivity of the material used. We also know that heat causes every material to expand depending upon their coefficient of expansion. A combination of these two phenomena is used in thermal overload relays.

Magnetic Overload Relay

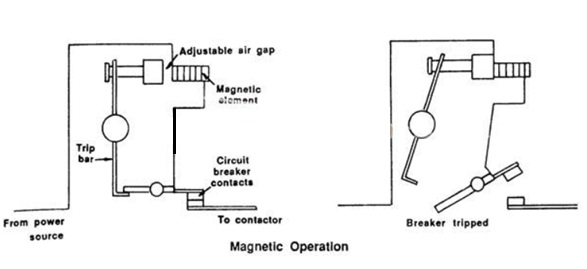

This type of relay is used in severe conditions of overloading which we may get due to some internal fault or short circuit and under such conditions, the tripping has to be almost instantaneous to avoid extensive damage. The principle of operation is the magnetic effect of current which is proportional to the magnitude of the current.

Magnetic Type

From the above diagram, it is clear as high current passes through the magnetic element it gets highly magnetized and pulls the core towards the coil. The core is attached to a trip lever which in turn disrupts the supply to the main contractor/circuit breaker thus tripping the supply to the gadget.

Also, we could have Dashpot type relays in which the plunger moves in a dashpot filled with oil, or we could have fusing element type OL relay which is smiler to a fuse element and uses the heating effect of current. These types of relays have now become obsolete.

Electronic Overload Relays

Electronic relays are now the order of the day and are gradually replacing all other relays. These relays are either microprocessor-based or numeric relays based on digital technology. Such relays come with many additional features like limiting the number of hot starts to a motor etc. The basic principle is to sample the current drawn by the gadget compare it with settings and then generating a trip signal. Overload relays are denoted by various symbols and do not have any common denotation. However, the most frequently used ones are simple, thermal type, and magnetic type.

Overload Relay Setting

Overload relay settings is a tricky part as there are many schools of thought on this, some say that it should be done at 70% of the full load current of the motor and some say it should be done at near full load current of the motor. However, many factors go into proper ranging and selecting the setting of overload relay. We shall be considering overload relay in a direct online configuration only.

- Let us first see the factors on which the current drawn by the motor after installation depends.

- Mechanical loading on the motor.

- The Quality of the supply i.e. the voltage variation the frequency variation and the combined effect of both.

- A service factor of the motor.

- To some extent environmental conditions and its upkeep.

Mechanical loading has a direct and major impact on the current drawn. As the quality of supply is not good, we have a large variation in voltage and frequency which also has an impact on the current drawn by the motor, but this variation could be up to say 10 to 15 percent. The service factor allows us to extra load the motor by 15%. The environmental conditions and upkeep (maintenance factor) have some nominal effects.

Considering all the above factors we have to select and set the overload relay. These factors are different for each application and therefore in my view, there cannot be any thumb rule for setting a relay. An overload relay should be set at about 10 to 15 percent above the actual load drawn by the motor. The purpose being to fully protect the motor and at the same time avoid the nuisance trappings. The range of the relay should be such that it allows a maximum setting of 10 to 20 percent above the full load current of the motor.

As an example, if we have to select the range of overload relay for a motor with a full load current of say 10 amperes it should be from 7 to 12 amperes or as near to it as possible.

Connection Diagram

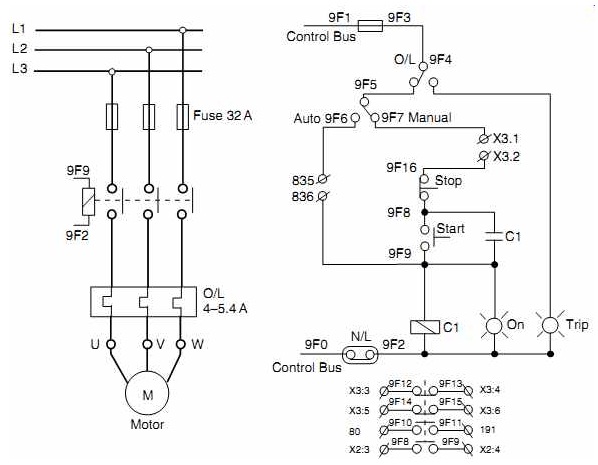

The overload relay connection diagram underneath shows the power and control connection diagram of the overload relay in a DOL configuration for a 2. KW Three-phase motor.

Connection Diagram

The connection diagram is self-explanatory showing the overload relay which is housed in a DOL starter and connected to the motor terminals. The circuit controls the tripping arrangement.

Overload Relay Applications

Overload relay is a protective device that should be used with every electrical device, but its use becomes very necessary with machines and appliances which frequently are subjected to overloading conditions. Some of them are given hereunder.

- Motors

- Transformers

- Generators

- Heaters

- Home appliances etc.

FAQs

1) What causes overload to trip?

Overloading (over current) causes the overload relay to trip.

2) What are the two basic types of relays?

The two-basic type of relays is thermal overload relays and magnetic overload relays.

3) How do you test the motor overload relay?

An overload relay can be tested by injecting specified current into it and then noting the time it takes in tripping. Comparing it with the characteristics required.

4) How many types of relays are there?

There are mainly three types of relays. Thermal overload relays, Magnetic overload relays, and electronic overload relays.

5) What is an electronic overload relay?

Electronic overload relays are those relays that use electronic devices like microprocessors, and other semiconductors.

Know more about RLC Circuit MCQs, Protective Relay MCQs. Electrical Contractor MCQs.

Know more about Distance Relay.

Thus, the overload relay is of utmost importance in the smooth and reliable operation of any electrical machine on the device. Thorough knowledge of it will make our maintenance systems not only reliable but safe also. Many advancements are taking place in this field, which is making overload relay more and more sophisticated and trustworthy.