Electric power is now the mainstay of many technologies and applications. This is the term that is used to know the energy transferred by the electric circuit. Through the electric power industry, power will be supplied to households and businesses. There are multiple approaches to power generation and every application requires various levels of power. The generation of power is handled by the electric power industry. There might be the chances of getting less amount of power or receiving huge loads of power which leads to complex situations. In this case, there has to be a device that works on checking the power quality and it is a “Power Analyzer”. This article is going to explain power analyzer design, connections, the working principle, and its related concepts.

What is Power Analyzer?

Power analyzers are the testing devices that hold more prominence in the electrical electronic domain because they operate to deliver power quality in various devices. Power quality is generally termed as compatibility between the source and load devices so that after checking the load’s power quality the device can perform properly. This resolves the issue of devices getting damaged that arise because of power issues. This device holds the ability to calculate various factors related to power utilization and generation of frequencies which range between 50 – 60 Hz and can be up to kilohertz.

When the quantity of power has a constant voltage supply that remains within specified limits, and its A.C frequency is constant which is near to the rated value having a smooth voltage curve, then the device possesses good power quality. But the power quality might differ because of service discontinuity, changes in voltage magnitude, harmonics increment in A.C power, and transient current. The power analyzer analyzes changes in voltage levels, stabilizations, swells, and many others in electric power.

Even there are multiple kinds of equipment used for measuring power, the power analyzers are manufactured to deliver the calculations necessary for analyzing devices that generate, covert, or utilize power. In this approach, a power analyzer provides an exact output that meets the requirement of electric engineers.

Working Principle

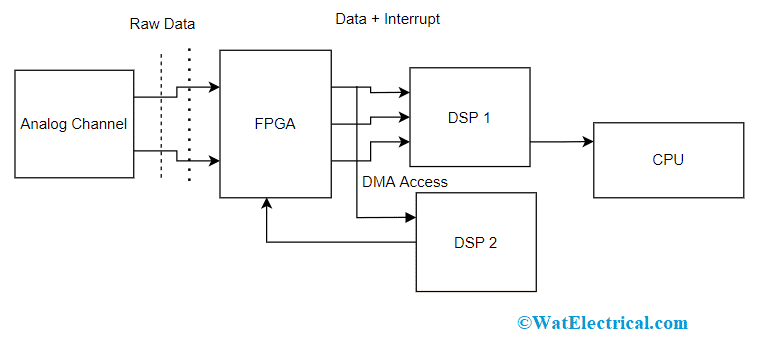

The working principle of the power analyzer can be known by looking at the below power analyzer circuit diagram.

Power Analyzer Circuit Diagram

A power analyzer generally includes two separate channels to provide input of voltage and current. The voltage input channel consists of an attenuator and the current input channel is included with an internal current shunt. The inputs from both the channels will undergo sampling and the sampled information is evaluated through a DSP processor. The device is also included with the FPGA unit where helps in interfacing all other sections. An individual CPU is also provided where this collects the input from the processor and displays output, stores the information, and also used for transmission of wireless channels.

This device is utilized for the measurement of energy flow in both the AC and DC current systems where there are separate considerations for the calculation of AC systems. The RMS time period of the electrical signal highlights every corresponding measurement achieved by the measuring device. This scenario seems to be intricate for AC calculations because RMS is usually represented as DC value. To know the exact RMS value of the AC signal, an average value needs to be measured for each AC frequency cycle. This is termed as the basic circuit’s frequency; the power analyzers can find out the digital frequency values to provide consistent RMS time periods at the time of power conversion.

This analyzer device also measures the current and voltage values of the system. General systems gain separate voltages through voltage dividers whereas a transformer is generally necessary for current calculation. This might consist of a coil that calculates the electric field in a wire that carries current.

When the voltage and current values are known by the power analyzer, then measuring power becomes easy.

Power Analyzer Measurements

- Based on the manufacturing type and model, power analyzers can measure multiple parameters. But the main operation of the device is to calculate the values of power, RMS-related values like peal value, mean and average values, current, phase, voltage, harmonics, and other factors.

- Few types of power analyzers are designed to know high power calculations and they might consist of high-powered sensors, while few measure the standby current constraints for different items of the devices.

- For the PA’s which are used in certain applications, they also have the logging abilities which corresponds that information onboard can be stored and later it can be downloaded. It is usually workable to communicate the information through USB or Ethernet so that additional analysis can be known.

- The devices can also be utilized for analyzing the devices that work for an extended period of time probably under multiple host conditions, and these information capabilities are most in use.

- Even power analyzers can be managed remotely. This allows the device to be located near to the item that is under test and the engineer and computer are placed at some other place. This is so beneficial when an item undergoes either vibration testing or temperature.

Apart from these, there are many other situations where a power analyzer is used for measurement.

Connection of Power Analyzers

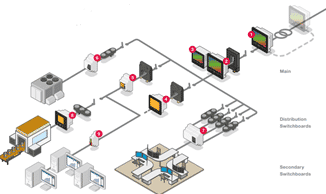

In the electric domain, the generation of power happens at a power generator. The generated power is then broadcasted to electric meters present at the user side through transmission lines. In order to have efficient monitoring, power analyzers are mainly installed at three locations which are at Mains, Secondary switchboards, and Distribution switchboards.

Mains – Here, the analyzers having enhanced performance, controlling voltage levels, and electrical variables are installed. These are mainly manufactured to have connections in medium or low-level voltage applications. These have the ability to provide info on analyzing additional features such as energy sources through impulses, heat, gas, or water meters.

Distribution Switchboards – Devices that are utilized for measuring electrical factors and energy utilization are located at distribution switchboards. These provide data corresponding to the significance of every electrical line along with stating any warning that appears.

Secondary Switchboards – Devices that are utilized for reading loads are located at the edge of secondary low voltage switchboards. These provide data pertaining to the utilization level and status of every electrical line or load.

As there exist various kinds of calculating electric parameters, the connection methods will also vary. In the direct current calculations, the circuit will be opened. And for indirect current, the connection is like that current transformer clamp has a connection with the wire to know the current value. Based on the operation, different types of PA’s are used.

For maintenance and analysis purposes, PA’s with clamps are needed where these need no additional connections. While the three-phase PA needs three clamps for measuring inputs.

Also, when the measuring current value lies within the maximum rated input value, then it has a direct connection with the current-carrying cable. Whereas the current value is more than the rated value, then it needs an external current transformer which is used for the conversion of the current into voltage.

The below picture depicts the power analyzer positioning.

Connections of Analyzer

Types of Power Analyzers

Here are the basic kinds of power analyzers explained by considering examples in each type

AC Power Analyzer – PA2100 is a type of AC power analyzer which allows multiple electrical power calculations to be considered concurrently at the time of testing. With this device, it is possible to known THD, power factor, voltage, harmonics, apparent power, and others. A few of the device characteristics are as below:

- Delivers accuracy of 0.2% even when there are distorted signals.

- It calculates inrush current

- The device has huge input bandwidth in the range of 5 – 250kHz

- Consists of LabView drivers

- Input impedance is in the range of 0.020 Ohms

DC Power Analyzer – N6705C is one of the DC power analyzers where it provides unbalanced productivity gains for the measurement of DC current and voltage values. This device is a package of an oscilloscope, four DC power supplies, a waveform generator, and a data logger. A few of the features of this DC power analyzer are:

- It requires no complex programming

- It has a large color graphics display

- It eliminates the requirement of collecting and configuring multiple devices

Advanced Power Analyzers

As mentioned in the introduction section itself the power analyzer not just measures power quality, it is used to calculate multiple mechanical energy values like speed, torque and also used for test bench and manufacturing purposes. The offers proper information for detailed investigations that allows the ability to know device performance and efficiency. Few of the additional measurement and approaches achieved through power analyzers consist of:

- Harmonic observations

- Can observe RMS time periods and basic power values

- Polar illustrations

- Fast Fourier Transforms

- Performance mapping

Power Analyzer Applications

The applications of power analyzer are:

- Used in ultrasonic cleaners, medical devices, and in induction heating

- Power factor modifications and harmonic calculations

- Employed in electronic devices like motor and DC drives, frequency inverters, UPS, triac, and thyristor regulators

- Four quadrant power systems

- Used for analyzing three-phase power transformers

- Used in household appliances like blenders, mixers, refrigerators, ovens, heaters, and many others

Know more about RL Circuit.

Know more about Power Systems MCQs.

On the whole, this is a detailed explanation on Power Analyzers. The article has provided a detailed analysis of the power analyzer working, its connection at various locations, circuits, types, and applications. Know how power analyzers are used in the devices that undergo vibration and temperature testing.