A transformer is an electrical device, used to enhance (step-up) or reduce (step down) the voltage & current in an AC system without a change within the frequency of AC in between electrical circuits. The output voltage in a step-up transformer is increased & the output current will be decreased whereas the output voltage in a step-down transformer is decreased & the output current will be increased to maintain the system’s input & output power equal. Generally, transformers work on the electromagnetic induction & mutual induction principle. Transformers are classified into two types based on their construction; shell type transformer and core-type transformer. This article discusses an overview of the shell-type transformer, their working, and their applications.

What is a Shell Type Transformer?

The shell-type transformer is a rectangular type electrical device where the core is surrounded by a significant part of the windings. This transformer has one central & two outer limbs where both the windings are arranged within the single limb. The main function of the two outer limbs is to complete the low reluctance path for magnetic flux. In this type of transformer, every winding is separated into subsections, wherever the high voltage winding & low voltage winding subsections are alternatively located on the central limb, so this winding is known as disc or sandwich winding.

Construction of Shell Type Transformer

The lamination of this transformer can be formed in the “E” & “I” shapes where these two shapes are simply connected in reverse directions with each other thus the maximum reluctance can be decreased at the joint. To eliminate the permanent joint, separately alternate coats are stacked

This type of transformer includes three main limbs with the whole current supplying within the middle limb whereas the remaining two limbs have limited flux. So its middle limb’s width can be enhanced to the external part. On the mile limb, both low and high-voltage windings are formed.

The low voltage winding can be arranged close to the core whereas the high voltage winding can be formed in the external element of the low voltage winding. So that the cost of insulation can be decreased & it is neatly arranged in between the windings. This winding’s shape is mostly cylindrical & core laminations are located on it.

Construction of Shell Type Transformer

Working

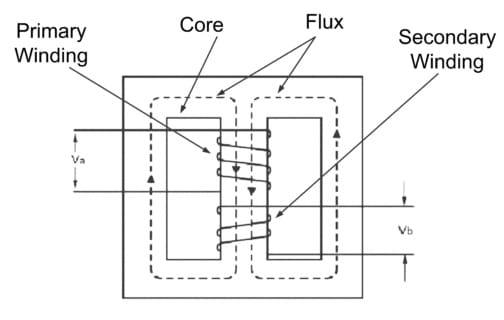

The working of shell type transformer is, that whenever alternating current supplies through the primary winding it will create a magnetic field in the region of the winding. This magnetic field will pass throughout the core & in the secondary winding it will induce a voltage where a load is connected.

This transformer’s core includes a series of laminated magnetic materials which are stacked jointly to make a closed magnetic circuit. This transformer’s laminations will help in decreasing the loss of energy because of eddy currents so these can occur whenever a magnetic field passes through a conductive material.

The windings of this transformer are arranged in the region of the core concentrically. So the primary winding is arranged on the external layer of the transformer whereas the secondary winding is arranged on the inside layer. These two windings are simply separated through an insulating layer which prevents any electrical short circuits in between them.

Winding of Shell Type Transformer

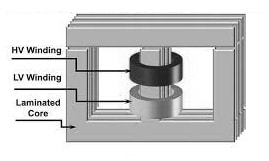

The winding of shell type transformer is HV & LV windings which are wounded longitudinally with the core. The HV windings are sandwiched between two LV windings. Since, both the windings are wounded on the surface of the central limb, and the required conductor quantity for windings of this transformer is low as compared to the core type transformer.

Here the necessity of insulation materials is more because the two windings are sandwiched on each other which could increase short-circuit faults. This transformer design is a bit complex as compared to the core type because of its winding structure. Any fault within the inner windings can only be attended to after eliminating all external windings thus the maintenance of winding is very hard in this transformer.

Windings

Cooling System

The shell-type transformer is made up of various components and every component has some particular cooling necessity. The power transformation process tends to produce a significant level of heat which is known as the efficient cooling system. The cooling system of shell-type transformers like forced air or forced oil cooling is significant because generated heat during transformer working cannot get dissipated simply from two windings because of surrounding limbs & yoke.

The air is pumped throughout the core & blown by a fan throughout the winding slots for cooling it down. Alternatively, oil is pumped simply into the core, wherever it mixes by the airflow to cool down the transformer windings. This oil can flow back to the reservoir through an inlet pipe.

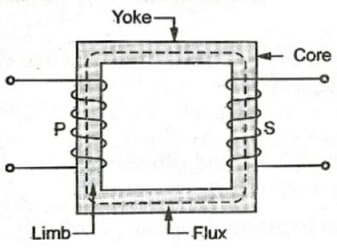

Limb of Shell Type Transformer

The limb of the type transformer is the vertical part wherever the windings are wounded. The limb core of this transformer is made up simply of many concentric windings, which are wound within a cyclic arrangement around the cylindrical core. This transformer includes a single central limb & two outer limbs. In this type of transformer, both the windings are arranged on the central limb whereas the two outer limbs are used to complete the low reluctance path for magnetic flux. The flow of current in the limb windings is maximum at one end & minimum at the other end.

Limb & Core of Transformer

The Core of Shell Type Transformer

The core is a significant component within the shell type of transformer which is mostly made with a ferromagnetic material like soft iron and also 3 to 5% small amount of silicon steel is included in this iron to increase the iron’s electrical resistivity thus decreasing eddy current losses. Here the silicon steel is mainly used for improving the core strength which helps in reducing the stress on the core.

Difference between Core Type and Shell Type Transformer

The difference between core type and shell type transformer include the following.

| Core Type Transformer | Shell Type Transformer |

| The lamination of this transformer is cut in the form of an L strip. | The lamination of this transformer is cut in the shape of the long L & E strips. |

| It needs more copper. | It needs less copper. |

| The cross-section shape of this transformer is square, three stepped & cruciform. | The cross-section shape of this transformer is rectangular. |

| It has three limbs. | It has two limbs. |

| It needs more insulation | It needs less insulation |

| The flux in this transformer is distributed equally on the core’s side limbs. | The central limb of this transformer carries the complete flux & side limbs carry half of the flux. |

| The windings of this transformer are arranged above the side limbs. | The windings of this transformer are arranged on the central limb |

| It has two magnetic circuits. | It has a single magnetic circuit. |

| It has more losses. | It has less loss. |

| This transformer has less mechanical strength. | This transformer has high mechanical strength. |

| Its average magnetic core length is longer. | Its average magnetic core length is shorter. |

| This transformer is preferred mostly for high power & high voltage applications. | This transformer is preferred mostly for low power & low-voltage applications. |

Advantages and Disadvantages

The advantages of shell-type transformers are discussed below.

- The core or iron losses of this transformer are less.

- This transformer’s efficiency is high.

- This transformer uses less copper conductor for its design thus this transformer cost is less.

- Its mechanical strength is good.

- Its size is compact.

- Its magnetic flux leakage is low.

- This transformer’s seismic-withstand ability is high.

- This transformer’s short circuit strength is very good.

- Its magnetic flux leakage control is good.

- These transformers have a larger surface area mainly for heat dissipation, which allows them to handle high power levels.

- These transformers have a longer lifespan.

- Its design is flexible & easily transportable.

- The cooling system of this transformer is excellent.

- The outflow of this transformer can be protected from magnetic flux.

The disadvantages of shell-type transformers include the following.

- This transformer repair is very difficult.

- These devices cannot provide normal cooling.

- This transformer uses Iron for its construction.

- Its production cost is high because of manpower costs.

- This transformer needs maintenance.

- Heat dissipation is not simple.

- It needs more insulation.

Applications

The applications of shell-type transformers include the following.

- Shell-type transformers are used for optimizing the cost of a circuit because the cross-sectional core of this transformer is square or rectangular which is very low cost.

- These transformers are used in low-voltage applications like; electronic circuits & converters within power electronics.

- Shell type transformer is used within electrical power transmission & distribution systems.

- These transformers are used most frequently in low & medium-voltage applications like industrial plants & power substations.

- These transformers are used in power transmission systems to increase or decrease the voltage of electrical power.

- Shell type transformer is used in industrial applications like welding, lighting & motor control.

- These transformers are used in railways for signaling & traction purposes.

- These transformers are used in renewable energy systems like solar power & wind power plants.

- This type of transformer is used within telecommunications systems for isolating various system parts and also provides power supply to various components.

What is the use of a shell-type transformer?

A shell-type transformer is used in low-voltage applications such as electronic circuits & power electronic converters.

What is a 3-phase shell-type transformer?

The transformer which is constructed by stacking three separate single-phase transformers is known as a 3-phase shell type transformer. This transformer’s three phases are independent as compared to the core-type transformer, while every phase has a separate magnetic circuit.

Which is better shell type or core type?

The shell type is preferred mainly for low voltage & low power applications whereas the core type is used mainly for high voltage & high power-based transformers. As compared to shell type, core type transformer cooling is better because of the directly exposed windings to the atmosphere.

Why shell type transformer used more widely?

Shell-type transformers provide a shorter magnetic path as compared to the core type. The leakage, flux & magnetizing current are low and it has more power transfer capacity.

Try to answer a few of these questions to know your understanding of Shell Type Transformer MCQs.

Thus, this is an overview of the shell-type transformer, construction, working, advantages, disadvantages, and its applications. This kind of transformer offers a shorter magnetic path as compared to the type of core. The leakage, magnetizing current & flux are lesser in this type of transformer as compared to the core type and also it has more power transfer capability. These transformers are frequently used wherever limited space is obtainable like in the railway industry, It is helpful to place these transformers above or below the carriages without enhancing the overall carriage height significantly. For trains, height is a particular concern because of aerodynamics & other considerations like passing below bridges. Here is a question for you, what is a core-type transformer?